In the world of metallic piping systems for pressure piping systems, SAES-L-110 sets forth specific limitations and guidelines. This standard serves as a comprehensive reference, extending and complementing the provisions outlined in the ASME B31.1, B31.3, B31.4, and B31.8 piping codes. This article is about technical specification of Pipe Joints and Components.

SAES-L-100 focuses on an array of critical aspects, including the selection and usage of metallic pipe fittings, bends, miters, laps, and branch connections within the domain of plant piping and pipelines. It’s important to note that specialized components like tube fittings and other specialty fittings are beyond the scope of this standard. This article also explains about SAES-L-110.

SAES-L-110Welded Joints in Piping Systems

The integrity and reliability of welded joints in metallic piping are of paramount importance, and SAES-L-100 lays down the foundation for ensuring their conformity. Let’s delve into the specific provisions concerning these welded joints:

5.1 Pipe Welds

- Welds within metallic piping must adhere to the exacting standards outlined in SAES-W-011, SAES-W-012, SAES-W-013, and other referenced standards.

- For joined pipes with a wall thickness ratio less than or equal to 1.5, the joint design must align with the respective ASME B31 design code.

- If the wall thickness ratio exceeds 1.5, the end preparations and geometry should comply with ASME B16.25, focusing on “Butt Welding Ends.”

- In cases where the wall thickness of the fitting or pipe at the welding end differs from the matching pipe, resulting in unequal external and/or internal diameters, the welded joint design shall adhere to the specifications in Figure 434.8.6-2 (a) of ASME B31.4.

5.2 Socket Welds

- The application of socket-welded joints in hazardous services should not exceed 1½-inch for new construction. An extension to 2 inches may be considered for maintenance, minor field modifications, and alignment with existing equipment connections.

- Socket-welded joints are discouraged for sour service. However, when their use is unavoidable, the maximum size allowed shall be 1-inch.

- Socket weld joints are strictly prohibited in locations prone to high vibration, such as high-velocity gas control valves and reciprocating pumps.

- Prior to welding, a specific axial gap requirement, depicted in Figure 328.5.2C of ASME B31.3, must be maintained, with a maximum of 3 mm and a minimum of 1.5 mm. This requirement applies to new socket weld installations for new construction, maintenance, and modification.

5.3 Fillet Welds

- The utilization of sleeve couplings, as per Standard Drawing AE-036760-001 and AB-036090-001, is restricted primarily to cement-lined pipes used in specific water services like firefighting piping systems and oily water service.

These meticulous regulations and guidelines ensure that welded joints in metallic piping systems meet the highest standards of safety and performance, aligning with the objectives of SAES-L-100.

Prohibited Piping Joints and Components

In accordance with SAES-L-100, specific piping joints and components are strictly prohibited within pressure piping systems. These proscribed elements are as follows:

a) Caulked Joints: Caulked joints, typically sealed with a caulking material or compound, are explicitly forbidden within the scope of SAES-L-100. These joints lack the reliability and structural integrity required for pressure piping systems.

b) Soldered, Brazed, and Braze-Welded Joints: Soldered, brazed, and braze-welded joints, while suitable for certain applications, do not meet the stringent requirements of pressure piping systems governed by SAES-L-100. These joints may not provide the necessary strength and leak-tightness for high-pressure environments.

c) Expanded Joints: Expanded joints, characterized by a slip-on design that employs an O-ring for pressure sealing, are not permitted. Such joints may not offer the robustness and safety required for pressure piping systems.

d) Bell-Type and Packed Joints: Unless otherwise explicitly specified in this standard document, the use of bell-type and packed joints is prohibited. These joints may lack the necessary sealing effectiveness and structural integrity needed for pressure piping systems.

By prohibiting these specific piping joints and components, SAES-L-100 ensures the safety, reliability, and compliance of pressure piping systems with the highest standards and requirements.

Threaded Joints

Threaded joints in piping systems are subject to specific guidelines and limitations according to SAES-L-100. Here’s an overview of the regulations regarding threaded joints:

7.1 Taper Pipe Thread (NPT): Threaded joints in metallic piping systems shall adhere to the taper pipe thread standard (NPT) as outlined in ASME B1.20.1, unless specific connections necessitate otherwise. It’s important to note that threaded connections for fire services must comply with SAES-B-017.

7.2 Hazardous Services: In hazardous services, the maximum allowable size for threaded connections is 1½ inches for standard fittings and valves. For maintenance, minor field modifications, or compatibility with threaded specialty devices like scraper signals and access fittings for corrosion monitoring, a maximum size of 2 inches is permitted. Threaded connections are not suitable for hydrogen service due to safety concerns.

7.3 Non-Hazardous Services: For non-hazardous services, threaded connections are permitted up to 3 inches for standard fittings and valves. However, on special items like fire hydrants, a maximum size of 4 inches is acceptable. Larger sizes can be approved by the assigned Chairman of the Piping Standards Committee for specific applications.

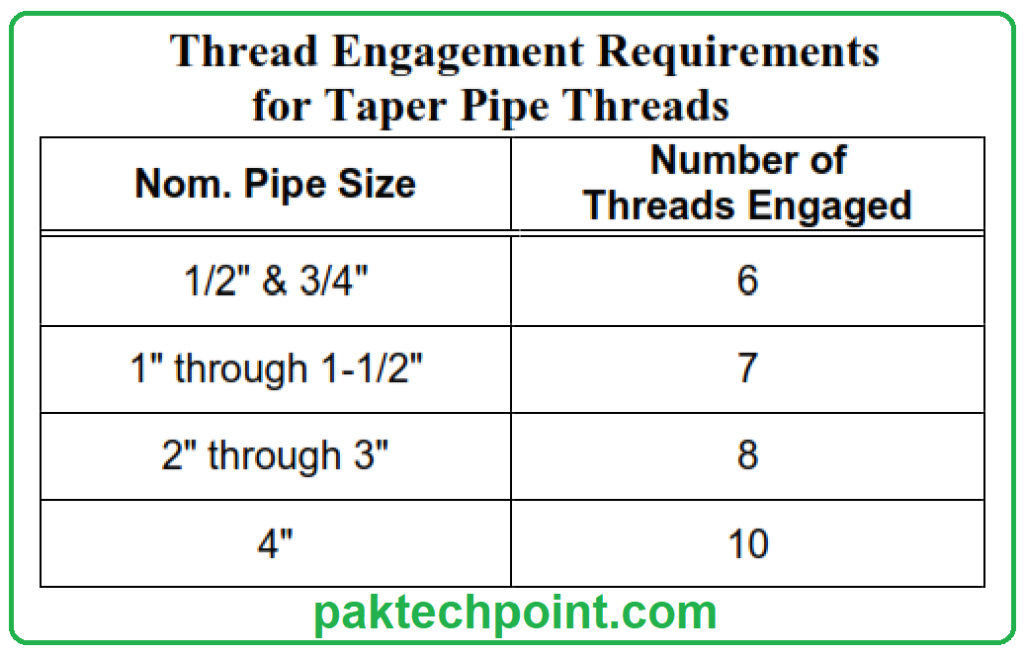

7.4 Thread Engagement: The minimum length of engaged threads on pipes must adhere to ASME B1.20.1 for taper pipe threads. Additionally, the minimum number of engaged pipe threads should meet the specifications outlined in following Table.

7.5 PTFE (Teflon) Tape Limitation: It’s essential to avoid using PTFE (Teflon) tape for threaded connections subjected to service temperatures exceeding 204°C. This limitation ensures the reliability and effectiveness of the joint under high-temperature conditions.

Commentary Note: Threaded joints should generally be avoided in scenarios where crevice corrosion, severe erosion, or cyclic conditions are anticipated, as their effectiveness and integrity might be compromised.

By adhering to these regulations, threaded joints within piping systems can be employed safely and effectively, ensuring the overall reliability and performance of the system.

Flanged Joints

Flanged joints in piping systems are subject to specific considerations and precautions outlined in SAES-L-100. Here’s an overview of the regulations regarding flanged joints:

8.1 Avoiding Flanged Connections: The use of flanged connections should be minimized when butt-welded joints can be employed. This avoidance is particularly relevant in the following scenarios:

- Services and locations prone to leaks (e.g., cyclic or vibration services).

- Situations where leaks could pose a significant hazard (e.g., potentially toxic materials).

- Services that are challenging to control effectively.

Specific cases include:

a) Steam in ASME class 900 pressure rating.

b) The fully restrained portion of cross-country pipelines and underwater pipelines.

c) Locations where piping will be subjected to substantial bending or external loads.

d) On buried piping systems.

8.2 Fire Hazardous Areas: Flanged connections with long exposed bolts, except for standard spectacle plates and blinds, should not be used in fire hazardous areas unless the bolting is adequately protected by a fire-resistant shield. Such protection is illustrated in Standard Drawing AC-036404-002 or an equivalent method, as referenced in SAES-B-006.

8.3 Flange Selection: The selection of flanges must adhere to the guidelines outlined in SAES-L-109, ensuring that the appropriate flange types and materials are chosen for specific applications.

By following these regulations and considerations, the use of flanged joints in piping systems can be made safer and more effective, with due attention to factors such as safety, reliability, and fire hazard prevention.

Seal Welding of Threaded Joints

Seal welding of threaded joints is a crucial practice to prevent leakage in specific services and applications within the context of SAES-L-100. Here are the key guidelines and requirements for seal welding of threaded joints:

9.1 Purpose of Seal Welding: Seal welding is employed to prevent leakage in threaded joints. It’s important to note that seal welding is not intended to contribute to the strength of the threaded joints.

9.2 Required Seal Welding: Seal welding of all threaded joints up to the first block valve is mandatory in the following services and applications:

a) All hydrocarbons.

b) Systems using ASME Class 300 and higher flange ratings for boiler feed water, condensate, and steam.

c) Services involving toxic materials such as chlorine, phenol, hydrogen sulfide, etc.

d) Services involving corrosive materials such as acids, caustics, etc.

e) Piping for oilfield chemicals (e.g., corrosion inhibitors, emulsifiers, electrolytes, etc.).

f) Piping subjected to vibration, whether continuous or intermittent.

9.3 Exceptions for Seal Welding: Seal welding is not required for the following services and applications:

a) Thermowells.

b) Bar stock plugs located downstream of a seal-welded block valve.

c) Special devices like access fittings and scraper signals.

d) Joints that need frequent disassembly and are downstream of a seal-welded block valve, such as sample connections.

e) Instrument piping downstream of the primary instrument isolation valve.

f) Pipe union ring threads and joints with elastomer o-rings.

g) Threaded joints downstream of a seal-welded root valve that discharge directly to an open drainage system or the atmosphere.

h) Extended body valves with integrally reinforced welding ends per API STD 602.

9.4 Seal Welding Specifications: In cases where seal welding is required, the seal weld should be a fillet weld originating from the outer diameter of the female part. It should have a smooth finish with slight concavity, as allowed by ASME B31. The weld should cover all exposed threads without undercut.

9.5 Prohibited Materials: The use of PTFE (Teflon) tape or joint compounds is not allowed in threaded connections that require seal welding.

By adhering to these guidelines and requirements, seal welding of threaded joints can effectively prevent leaks in critical services and applications, ensuring safety and reliability in the piping system.

Pipe Fittings General Requirements

In the realm of metallic piping systems, specific requirements and standards must be met for pipe fittings to guarantee compatibility and compliance. Here are the general stipulations for pipe fittings:

10.1 Compatibility and Limitations:

- All metallic pipe fittings must be fully compatible with the adjoining pipe. They must adhere to the limitations outlined in SAES-L-136, especially when applied to carbon steel line pipe.

10.2 Approved Manufacturer:

- Pipe fittings should be procured exclusively from manufacturers approved in accordance with SAES-L-101.

10.3 Carbon Steel Fittings:

- Carbon steel fittings must meet the requirements specified in 02-SAMSS-005, ensuring that they adhere to industry standards and regulations.

10.4 Additional Requirements for Low-Temperature Service:

- For services operating within a design minimum temperature range of minus 18°C to minus 45°C, pipe fittings must comply with additional requirements, the specifics of which can be found in the relevant standards and guidelines.

By adhering to these general requirements for pipe fittings, you can ensure the compatibility and compliance of these crucial components within your metallic piping systems. This, in turn, promotes the safety and efficiency of your overall infrastructure.

Threaded and Socket Welding Fittings

When it comes to threaded and socket welding fittings in steel piping systems, adherence to specific standards and guidelines is critical to maintain safety and compliance. Here are the key requirements for these fittings:

11.1 Compliance with ASME B16.11:

- For steel piping in hazardous services, threaded and socket welding fittings must conform to ASME B16.11 standards, specifically Class 3000, Class 6000, or higher, as applicable.

11.2 Pipe Unions in Hazardous Services:

- Pipe unions used in hazardous services are limited to Class 3000 threaded or socket welding forged steel unions, following MSS SP-83 standards. Materials should be either carbon steel per ASTM A105, ASTM A350, or alloy steel per ASTM A182. It’s important to note that pipe unions should not be installed between the main pipe run and the root valve.

11.3 Limitations on Bushings:

- Threaded bushings with one size reduction are not allowed. When bushings are permitted, only hex head steel bushings are acceptable. Flush steel bushings are not permitted.

11.4 Forged Steel Welding Bosses:

- Welding bosses must be forged steel and should adhere to ASTM A105, ASTM A350, or ASTM A182 standards, as applicable. Refer to approved design standards, such as Standard Drawings AE-036175-001 or AD-036643-001.

11.5 Integrally Reinforced Welding Outlets:

- Integrally reinforced welding outlets, such as Weldolets, Threadolets, and Sockolets, in Class 3000, 6000, or higher, are acceptable when they abut the pipe wall with a full penetration weld.

11.6 Malleable Iron Fittings:

- Malleable iron screwed fittings must conform to ASME B16.3 Class 150 standards. They should be galvanized and are limited to use in non-hazardous services. Pipe unions in this category must be Class 300.

11.7 Pipe Plugs:

- Solid body, bar-stock, or forged steel plugs in accordance with ASME B16.11 standards are required for use in metallic piping systems.

Adhering to these specific requirements ensures the proper selection and use of threaded and socket welding fittings in steel piping systems, contributing to the safety and reliability of the overall infrastructure.

Steel Butt Welding Fittings

The selection and use of steel butt welding fittings in piping systems involve strict adherence to standards and guidelines. Here are the key requirements for these fittings:

12.1 Material and Purchasing Requirements:

- Carbon steel buttweld fittings must adhere to specific material and purchasing requirements. For fittings falling under ASTM A234 Grade WPB and MSS SP-75, compliance with the requirements of 02-SAMSS-005 is mandatory.

12.2 Conformity to 02-SAMSS-005:

- All steel butt welding fittings should conform to the provisions outlined in 02-SAMSS-005.

12.3 Integrally Reinforced Welding Outlets:

- Integrally reinforced welding outlets, if not listed in the SAMS Catalog, must follow a design that has been approved by the Chairman of the Piping Standards Committee. Additionally, refer to SAES-L-350 for any post-weld heat treatment requirements related to welding outlets.

12.4 Miter Elbows and Bends:

- Miter elbows are not permitted in piping systems. In cases where miter bends are deemed necessary, prior approval from the Chairman of the Piping Standards Committee is required.

Adherence to these stringent specifications ensures the proper selection and use of steel butt welding fittings, contributing to the integrity and safety of the piping infrastructure.

Branch Connection Types and Fittings

Branch Connection Types and Fittings in Piping Systems

Selecting the appropriate branch connection type and fittings in piping systems is crucial for ensuring structural integrity and operational safety. Here are the key considerations for branch connections:

13.1 Selection of Tee Branch Connection Type and Fittings:

- When choosing the tee branch connection type and fittings for new construction of metallic piping, reference Chart 1 for guidance.

- If a branch connection with reinforcement is selected as per paragraph 13.1.1, ensure that the size of the reinforcement pad complies with the applicable code.

13.2 Laterals and Crosses:

- Crosses are not allowed in piping systems. Instead, laterals should be used only when mandated by Saudi Aramco standards, particularly for low-pressure systems (pressure less than 150 psig), such as flare lines.

- Laterals must be designed to have a bursting strength that is at least equivalent to the bursting strength of the adjacent pipe.

- When fabricating laterals by welding the branch pipe directly to the run pipe, they should adhere to relevant codes and incorporate complete encirclement reinforcement. These laterals should be shop-fabricated in line with 01-SAMSS-010 and subjected to a minimum hydrotest pressure of 90% SMYS (Specified Minimum Yield Strength).

13.3 Branch Connections on Tees, Elbows, and Reducers:

- Branch connections on tees, elbows, and reducers, such as those for drain and vent connections, are generally not allowed.

- In situations where avoiding these connections is not feasible, the piping design should undergo a thorough review and gain approval from the Chairman of the Piping Standards Committee to ensure compliance with safety and integrity standards.

Careful consideration of branch connection types and fittings is essential to maintain the reliability and safety of piping systems, especially in the context of various construction scenarios and operational requirements.

![Limitations on Pipe Joints and Components | SAES-L-110 [PDF]](https://paktechpoint.com/wp-content/uploads/2023/08/image-145-984x1024.png)

This article is sourced from following documents.

Industry Codes and Standards Sourced for Article

American Petroleum Institute

API SPEC 6A – Wellhead and Christmas Tree Equipment

API STD 602 – Compact Steel Gate Valves – Flanged, Threaded, Welding, and Extended-Body Ends

American Society of Mechanical Engineers

ASME B16.11 – Forged Steel Fittings, Socket-Welding and Threaded

ASME B1.20.1 – Pipe Threads, General Purpose (Inch)

ASME B16.25 – Buttwelding Ends

ASME B16.3 – Malleable Iron Threaded Fittings

ASME B16.9 – Factory-Made Wrought Buttwelding Fittings

ASME B31.1 – Power Piping

ASME B31.3 – Process Piping

ASME B31.4 – Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids

ASME B31.8 – Gas Transmission and Distribution Piping Systems

ASME SEC VIII D2 Pressure Vessels, Alternative Design

American Society for Testing and Materials

ASTM A105 – Standard Specification for Carbon Steel Forgings for Piping Applications

ASTM A182 – Standard Specification for Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings, and Valves.

and Parts for High-Temperature Service

ASTM A234 – Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service

ASTM A350 – Standard Specification for Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components

Manufacturers Standardization Society

MSS SP-43 – Wrought Stainless Steel Butt-Welding Fittings

MSS SP-75 – Specification for High Test Wrought Butt Welding Fittings

MSS SP-79 – Socket-Welding Reducer Inserts

MSS SP-83 – Steel Pipe Unions, Socket-Welding and Threaded

MSS SP-95 – Swaged (d) Nipples and Bull Plugs

MSS SP-97 – Integrally Reinforced Forged Branch Outlet Fittings Socket Welding, Threaded, and Buttwelding Ends

International Standardization Organization

ISO 15156 – Petroleum and Natural Gas Industries Materials for use in H2S-Containing Environments in Oil and Gas Production.