Questions To Ask When Designing Or Specifying A Vibration Monitoring System

1. What Sensor Should I Select For Absolute Vibration Measurements?

Accelerometers offer the most flexibility in terms of frequency and dynamic range, but for that reason may measure more than is needed (high frequency and high acceleration events

that are not of interest). Velocity sensors can focus in on the cyclic vibration and offer a noise advantage since integration is carried out in the sensor and not the monitor. For best noise and sensitivity performance, utilise an electrodynamic based sensor which can drive long cables and offer excellent noise immunity.

2. What Sensor Should I Select For Relative Vibration Measurements?

Proximity probe systems can offer micrometre vibration measurement accuracy with noncontact probes. These are mounted relative to the shaft through various methods and are available in two main mechanical formats.

A straight mount format for simple bracketry and reverse mount for specific probe holder mounting where the shaft environment may be sealed. Be careful with selecting the cable length – proximity probes are available in typically 5m, 7m and 9m lengths depending on application.

3. Where Should The Sensor Be Fitted?

Proximity probes are offered up close to the shaft since they have limited range and are typically gapped at 1.0mm. Absolute vibration sensors should be mounted as close to the

bearing as possible, at a point that maintains good mechanical connectivity to the bearing. It is also typical in most applications to measure in both horizontal and vertical directions to

ensure all vibration signatures are captured.

4. What Electrical Interface Is Needed For The Sensor?

Proximity probes operate on a -24Vdc system and monitors provide the required interface. However, vibration sensors have a range of interfaces, the most common being IEPE which

powers the sensor through a current source arrangement. This offers good noise immunity and allows long cable runs between the sensor and monitor. Three –wire sensors have the

current source built in and are typically powered from +24V or +12V. Electrodynamic velocity sensors require no power supply at all as they are self-generating – however, care should be taken in terminating the sensor as different loads result in different sensitivities.

5. What Do I Need To Consider For The Sensor Environment?

Most sensors offer operation up to 120 deg C; above this, more specialised sensors are required. Both accelerometers and velocity sensors are available up to typically 450 degC

applications. Are the sensors mounted inside or outside of a building? Outside sensors may need to consider additional protection from the elements. Selecting a sensor with the

appropriate IP rating will assist in matching the sealing requirement. Customised designs are likely to be needed for high pressure environments such as Subsea which require specialised sealing and careful material selection.

6. What Distance Can I Have Between Sensors And Monitoring Equipment?

Most sensors are designed to be remote from the monitoring equipment, capable of providing accurate signals at distances above 300m. However, choice of cable impacts on

distance, as does the environment the cable is passing through. Individually screened twisted pairs or triads should be selected where possible for the sensor signals.

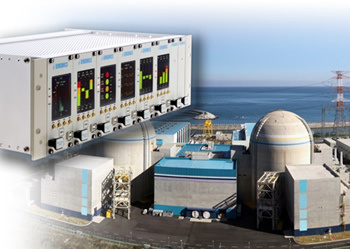

7. What Vibration Monitors Should I Select For Turbine Monitoring?

Turbine monitoring is usually quite a bit more complex than a standard motor or pump. In addition to vibration, it is typical to measure expansion of rotors, speed and maybe valve

position. Select a monitoring system with flexibility to suit these measurements. Rack-based is preferred for larger multichannel systems and and redundancy should be considered for

critical measurements.

8. What Power Supply Arrangement Should I Have For My Vibration Monitoring System?

This arrangement depends on the criticality of the monitoring. Rack-based systems are typical with dual redundant power supplies to protect against failure. The power supplies

should also be hot swappable. The source supply can be either 110/220 VAC or +24Vdc – dual redundancy is normally available for these inputs.

9. What Type Of Sensor Should I Use For A High Temperature System?

In turbines, engines and other high-temperature machinery, vibrations are monitored through a specialised velocity or acceleration sensor which will not have internal electronics.

For the accelerometer it is typical for the sensor to provide a charge output, therefore a separate low noise cable and charge amplifier will be needed to convert the signal to a

voltage or current. A non-contact eddy probe, or proximity probe (for displacement measurements) will not provide an accurate reading at temperatures above 120°C.

10. What Amplitude Sensitivity Range Is Required For My Monitoring System?

This depends on the amplitude of the vibrations produced by your machine at the point of measurement. Most acceleration sensors have a sensitivity between 10 – 100 mV/g. For high frequency vibrations it is usual to select a low sensitivity sensor since the acceleration levels can be excessive. High sensitivity sensors have a lower amplitude detection range, and should only be used in specialist applications with a low frequency operating range. If the peak g level is greater than the sensor’s acceleration range, there is a risk of amplifier

overload, which distorts the acceleration signal and produces inaccurate data.

11. How Do I Choose A Sensor With The Appropriate Frequency Range?

The sensor selection will depend on the operating frequency of your plant. If the frequency range is not already known, a test sensor can be placed on key locations of the machine.

Most rotating plant operates at a frequency of less than 100 Hz but harmonics of the running speed also need to be considered. Some auxiliary systems on the equipment can

have a higher operating frequency which may not be of interest. But generally, the sensor frequency range is determined by the make up of the plant (rotors, gearbox etc), the shaft

rotational speed, and the type of bearings that support the rotating shaft.

12. How Do I Guarantee Accurate Vibration Readings At High Temperatures?

High operating temperatures can affect the sensitivity of sensors to vibrations, and in some cases result in erroneous readings. In high sensitivity systems, sudden changes in

temperature – e.g. from hot air gusts or fluid spills – can cause components to react and affect your readings. To reduce sensitivity to these changes, install a thermal isolating sleeve

or mount with your sensor.

13. What Precautions Should I Take In Humid Environments?

Vibration sensors should be correctly sealed to prevent the entry of moisture – as this can affect the accuracy of your sensors and cause premature failure. If the plant is designed for

operation in wet or humid environments, all cabling and connectors should be equipped with the appropriate glands, jackets and coverings.

14. Are Vibration Monitoring Systems Suitable For Plant Operating In Hazardous Conditions?

Many rotating machines and turbines operate in the presence of flammable petrochemicals, gases or combustible particles. In such volatile conditions, piezoelectric devices are capable of generating large voltages with the potential for an explosion risk. Fortunately, modern vibration sensors are designed to be intrinsically safe for these applications, with limits placed on the thermal and electrical energy produced by each sensor. This mitigates against the risk of explosion or fire, but sensor type and safety barrier selection are key to meeting the required regulations, so if in any doubt please check with the equipment manufacturer.