LV/MV Motor Control Center (MCC) Testing Procedure | Method Statement

Current transformer (CT) test procedure:

a- Test objective:

– This test is considered as one of the main test, it’s aimed to test:

- Current transformer ratio.

- Current transformer polarity.

- Burden of current transformer.

- Knee point of current transformer.

- Current transformer winding resistance.

- Magnetization curve of current transformer.

- Megger test (insulation test).

b- Required Equipment:

- Current transformer (CT) analyzer.

- Megger.

c- Mechanical check and visual inspection:

- Check tightness of all connection.

- Check ferrules.

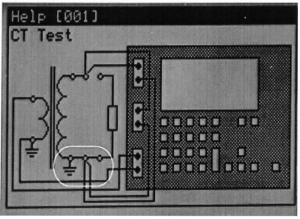

d- Current transformer analyzer connection:

- CT analyzer has 4 leads, two should be connected to primary side which contains primary side of CT and other two should be connected to secondary side of CT which you want to check its ratio.

- After connecting CT analyzer through laptop and using CT analyzer software, test can be started and result can be printed out for CT ratio, CT polarity, CT burden, CT knee point & CT winding resistance.

- This result should be compared with current transformer factory test and be sure that result within acceptable tolerance.

- To measure the burden: Inject 1 ampere on secondary side of CT, and using multi-meter you can measure voltage calculate burden by multiply voltage and current and compare it with CT Buden.

- To test insulation: Using megger by 1 kilo volt injection for 1 minute, this test should be done between primary to secondary, Primary to ground and secondary to secondary.

- See figure.1 which shows CT analyzer connection for CT TEST.

Voltage transformer (VT) test procedure:

a- Test objective:

– This test also is considered as one of the main test and its purpose is to test:

- Voltage transformer ratio.

- Voltage transformer polarity.

- Voltage transformer winding resistance.

- Megger test (insulation).

b- Required equipment:

- CPC100.

- Multi-meter (Fluke).

c- Mechanical checked and visual inspection:

- Check tightness of connection.

- Check ferrules.

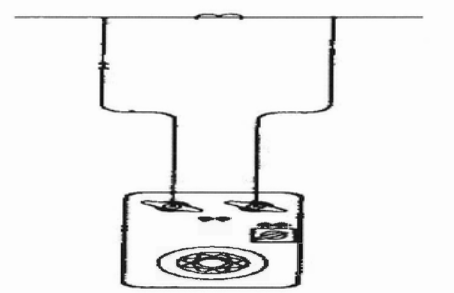

d- Voltage transformer test connection:

- Connect two leads from CPC device to primary side of voltage transformer and other two lead of CPC with secondary side of VT, then press start from VT page of CPC.

- Using CPC with same connection but from different page, you can measure winding resistance.

- To check the loop burden: inject the rated secondary voltage and measure the current. Burden will be the injected voltage measured current and then compare it with VT burden.

- Insulation test: Using megger to test insulation by 1 kilo volt injection for 1 minute, this test should be done between primary to secondary, primary to ground and secondary to ground.

- See figure.2 which shows connection of VT Test.

Trip Time test for Molded Case Circuit Breaker (MCCB) and megger test:

a- Test objective:

This test aimed to test the trip time for circuit breaker in case of over current or short circuit and to be sure that tripping time within acceptable range.

b- Required equipment:

- Primary injection tester. (Or special test kit to test the CB)

- Megger

c- Timing and megger test connection:

- To test trip time: there are three setting in each MCCB first setting is (long = ‘L’), second is (Short=’S’) and third is (Instantaneous=’I’).

- To test (L): adjust L on min. setting which is considered percentage from rated current, inject the setting current using primary injection tester and measure the time to be tripped, compare the value of tripping time with the value of setting time if its within acceptable tolerance or not.

- To test (S): adjust Son min. setting which is considered percentage from rated current, inject the setting current using primary injection tester and measure the time to be tripped, compare the value of tripping time with the value of setting time if its within acceptable tolerance or not.

- To test (I): adjust I on min. setting which is considered percentage from rated current, inject the setting current [if the value of injected current can be injected by tester as in some cases the min value of (I) is equal to 10 and rated current is 500 A, so to test you should inject 5000 ampere which isn’t applicable] using primary injection tester and measure the time to be tripped, compare the value of tripping time with the value of setting time if its within acceptable tolerance or not.

- To start megger test: this test is applicable for CB which rated current greater than 100 Amp. when breaker open inject 5 KV for 1 minutes, between the same pole (red-red, yellow-yellow and blue blue) and when breaker close inject 1 KV for 1 minutes between pole and ground, between pole to pole.

Contact resistance test for bus bar and circuit breaker:

a- Test objective:

- For contact Resistance, this test is aimed to measure the resistance of bus bar and for circuit breaker after being installed in the site to avoid high resistance which may be results from welding or installing in the site.

- For high potential this test is aimed to measure and test the withstand of the insulations and isolators against the high voltage without break down.

b- Required equipment:

Micro-ohm meter Contact resistance device.

c- Contact resistance test connection

- Contact resistance device has 4 leads, two for current and others for voltage, it depend on current injection on bus bar or circuit breaker then sense the voltage and calculate resistance by divide voltage on current (ohm’s law)

- Connect current leads between the device which you want to measure its resistance, connect voltage leads on the same terminals of current then hold your hand on contact resistance pushbutton, after few second the result will be displayed.

- See figure.3 which shows connection of Contact Resistance Test.

High potential for MV MCC bus bar and contactor:

a- Test objective:

For high potential this test is aimed to measure and test the withstand of the insulations and isolators against the high voltage without break down.

b- Required equipment:

High potential test kit.

c- High potential AC test:

- Insulation test by megger for 1 minute 3 phases line to line and line to ground.

- Applying high potential AC voltage on the bus bar or contactor line to line and line to ground.

- Take the record of passing current in mille Amperes from the high potential test kit.

- Insulation test by megger for 1 minute 3 phases line to line and line to ground.

- Compare the insulation test results to gathers before and after high potential test.

Miniature Circuit Breaker (MCB):

a- Test objective:

This test aimed to test the trip time characteristic of MCB if it’s within limits or no and check MCB auxiliary contact if it is available.

b- Required equipment:

- Sverker (used as current source).

- Multi-meter.

c- Mechanical checked and visual inspection:

- Check tightness for all wires.

- Check ferrules.

- Check for physical damage or defect.

d- Test connection and procedure:

- Connect sverker (which used as current source) direct to MCB, check MCB type and its rated current value.

- Inject from sverker twice of its rated current and measure the trip lime in which MCB will be tripped, compare the measured trip time with its acceptable limit from MCB manual depending on its type.

- Auxiliary contact should be checked in both condition of MCB (open/close) and check that auxiliary contact change its status from being open to close or vise, depending on its nature Normally open or Normally close.

Auxiliary relay test:

a- Test objective:

This test aimed to test relay’s output contact, pick-up and drop off voltage, operating and resetting time.

b- Required equipment:

- Sverker (used as Voltage source and used its voltmeter).

- Multi-meter [used as Ammeter].

- Miniature Circuit Breaker 2Pole (MCB).

c- Mechanical check and visual inspection:

- Check tightness for all wires.

- Check ferrules.

- Check for physical damage or defect.

d- Test connection:

i- Check output contact:

Our Auxiliary relay has several points, 2 used for Coil, before injecting any voltage on Auxiliary relay’s Coil, check contacts at its normal condition which mean Normally Open (NO) contact is being opened and Normally Closed (NC) contact is being closed, Inject the desired control voltage of Aux. coil {which is normally 120 volt AC), at which Aux. relay will pick up that’s mean its contact will change its position i.e NO contact will be closed and NC contact will be opened.

ii- Pick-up and drop off current and voltage:

- Pick up voltage can be measured using voltmeter when the coil voltage is increased gradually from 0 volt , the Aux. relay will operate (i.e Contacts change its normal status No will be closed and vice versa) at a certain voltage. This voltage is called pick-up voltage, Record the reading of voltmeter and Ammeter which is pick-up voltage and current.

- Drop-off voltage can be measured using voltmeter when the coil voltage on an operate relay is decreased gradually, the relay will release (i.e its contact will return to its normal status) at a certain

voltage. This voltage is called drop-off voltage, Record the reading of Ammeter which is drop-off current.

iii- Operating and resetting time:

- Adjust voltage source at the coil operation voltage of Aux. relay (in our case 120 v AC), To get operating time, adjust sverker at (on+time location) and switched MCB ON, To get resetting time, readjust voltage source at 120 volt AC and switch MCB OFF.

iv- Burden test:

- Adjust voltage source (sverker) at 120 volt AC, select on position and make MCB ON.

- Record reading of Ammeter.

- Calculate burden by multiplying coil operated voltage and reading of Ammeter.

Ammeter and voltmeter test:

a- Test objective:

This test is aimed to calibrate and adjust the reading of ammeter and voltmeter test.

b- Required equipment:

FREJA 300.

c- Mechanical checked and visual inspection:

- Checked tightness of all connections.

- Checked ferrules.

- Inspection for physical damage or defects.

d- Test connection and procedure:

- Set the VT ratio (for voltmeter) and CT ratio (for ammeter).

- Inject different values (min. 3 values) of current (in case of ammeter) and voltage (in case of voltmeter) and compare the injected values with reading values, calculate error in each reading and check that its percentage error within the acceptable range.

Current transformer loop:

a- Test objective:

This test aimed to check all current transformer loop, starting from first panel and distributed in thewhole switchgear depending on scheme, check shorting facility in terminal block [if exist].

b- Required equipment:

- FREJA (used as current injection).

- Multi-meter.

- Mini- clamp.

c- Mechanical check and visual inspection:

- Check tightness of all connection.

- Check ferrules for the whole looping.

- Check the single earth point.

d- Test connection

- Connect three phase current from FREJA to secondary side of current transformer, inject three phase current by different values and use mini-clamp to measure current in each phase and follow the loop until the last point.

Voltage transformer loop:

a- Test objective:

This test is aimed to check the whole loop of VT starting from first panel and distributed in the whole substation depending on scheme (i.e. metering or protection purpose)

b- Required equipment:

- FREJA.

- Multi-meter.

c- Mechanical check and visual inspection:

03 Check all voltage transformer loops.

d- Test connection:

Connect FREJA which considered as voltage source to secondary side of VT, inject three phase voltage with different values on each phase and then use multi-meter to measure the voltage on the whole loop starting from first panel to different location depending on the function of each VT.

Primary injection test:

a- Test objective:

This test aimed to check that the selected ratio of current transformer is correct and current transformer relay setting is OK and considered as back-up test of CT loop.

b- Required equipment:

-

- Primary Injection Tester.

- Multi-meter.

- Mini-clamp.

- Power-clamp meter.

c- Mechanical check and visual inspection:

Check that all current transformer terminal block is tightened and normalized.

d- Test connection:

-

- Connect Primary Injection Tester to inject current on bus bar including current transformer.

- Start injection of current, using power clamp we can measure the injected current to make sure that injected current which appear on screen of primary injection tester is same as the actual injected current, then using of mini-clamp, we can measure the current at each point of the loop and read the primary current value on each relay.

MCC Function test:

a- Test objective:

This test is considered as a major test or combined test for the whole work in MCC panels and finalizing phase for MCC panels.

b- Required equipment:

No equipment used.

c- Mechanical checked and visual inspection:

Inspect for the whole panel if any missing or damage device which can be resulted from installation.

d- Test procedure:

- Check the circuit of closing command for contactor.

- Check the circuit of opening command for contactor.

- Check mechanical interlock.

- Check interlock of closing the contactor.

- Check alarm signal from source up to relay.

- Check inter trip between upper voltage level CB and switchgear CB, between lower voltage levels CB and switchgear CB.

- Confirm the relay logic.

Protection relay (Main relay):

a- Test objective:

This test aimed to test function of main relay according to approved final setting for each one, but here we generally discussed main function which should be exist in most of approved final setting.

b- Required Equipment:

-

- FREJA 300.

- Multi-meter.

- Wires.

c- Mechanical check and visual inspection:

-

- Check for physical damage or defects.

- Check case earth.

- Check indication and LEDs.

- Check test switch for correct operation either shorting CT if exist or isolation of binary inputs/outputs.

d- Burden test

-

- Adjust voltage source at 120 volt AC.

- Record reading of Ammeter in case of all binary output deactivated and in case of binary output activation.

- Calculate burden in case of normal operation (all binary output deactivated) and abnormal operation (in case of binary output activated) by multiplying voltage and reading of ammeter.

- Compare the result with existing burden exist in relay manual.

e- Test connection and test procedure:

i. Binary input/output check:

-

- To test binary input: Apply rated binary input DC voltage on each input and verify the status of the input through relay’s software or from relay’s LCD [if exist].

- To test binary output: Using relay’s software you can force binary output to close for certain time and using multi-meter you can measure binary output contact resistance it should be around zero which indicates binary output being closed.

ii. Measurements

-

- Set CT ratio and VT ratio which used to the relay by studying the scheme.

- By using FREJA we inject secondary rated voltage and secondary rated current

- Record the primary value reading at relay’s screen.

iii. Instantaneous earth fault (50N):

-

- Pickup and drop off test: gradually increase secondary current to each phase separately in steps, until the LED which you used to indicate inst. Earth fault to operate this is considered pick-up value.

The current must be reduced in the same manner until the LED reset and then this considered as drop-off value. - LED reset and then this considered as drop-off value.

- Limits: then calculate the error and compare the error value with acceptable tolerance error that exists in manual of relay.

- Timing test: set each phase separately to amount of current equal to 22ls, then inject this value of current and measure the time taken to close binary output of the relay which indicates that inst. E.F.

- Limits: then calculate the error and compare the error value with acceptable tolerance error that exist in manual of relay.

- Pickup and drop off test: gradually increase secondary current to each phase separately in steps, until the LED which you used to indicate inst. Earth fault to operate this is considered pick-up value.

iv. Time delayed earth fault (51 N):

-

- Pickup and drop off test: gradually increase secondary current to each phase separately in steps, until the LED which you used to indicate inst. Earth fault to operate this is considered pick-up value. The current must be reduced in the same manner until the LED reset and then this considered as drop OFF value.

- Limits: then calculate the error and compare the error value with acceptable tolerance error that exists in manual of relay.

- Timing test: set each phase separately to amount of current equal to 2’2ls, then inject this value of current and measure the time taken to close binary output of the relay which indicates that inst. Earth fault.

- Limits: Limits: then calculate the error and compare the error value with acceptable tolerance error that exist in manual of relay.

Timing test for MV MCC Contactors and megger test:

a- Test objective:

This test aimed to test the closing/opening time for contactors and to make sure that there is no pole discrepancies between poles (red, yellow and blue) and contactors closing/opening time within acceptable range according to factory test result.

b- Required equipment

-

- SVERKER 670

- Megger

- Miniature Circuit Breaker 2Pole (2MCB)

c- Timing and megger test connection

-

- Connect the line 120V AC supply Through 1 pole MCB and the neutral direct to Contactor coil for closing (in case of measurement of closing time) circuit or opening (in case of measurement of opening time) circuit, for switching device that should be tested.

- To get closing/ opening time, the other pole of MCB will make start initiation for the SVERKER to measure the time and then put sverker at (on+time location) and switch MCB ON and then the main poles of contactor will make stop.

- The displayed time of contactor closing / opening is time between start and stop initiation. To start megger test when contactors open inject 2.5 KV for 1 minutes between the same pole (red red, yellow-yellow and blue-blue) and when breaker/contactors close inject 2.5 KV for 1 minutes between pole and ground, between pole to pole.

Contact resistance test for contactors:

a- Test objective:

This test is aimed to measure the resistance of contactor after being installed in the site to avoid high resistance which may be results from welding or installing in the site.

b- Required equipment

Micro-ohm meter Contact resistance device.

c- Contact resistance test connection:

-

- Contact resistance device has 4 leads, two for current and others for voltage, it depend on current injection on contactors then sense the voltage and calculate resistance by divide voltage on current (ohm’s law).

- Connect current leads between the device which you want to measure its resistance, connect voltage leads on the same terminals of current then hold your hand on contact resistance pushbutton, after few second the result will be displayed.

- The contactor shall be removed during test for visual inspection.

- See figure.3 which shows connection of Contact Resistance Test.

RTD Relay Check:

a- Test objective:

This test is aimed to measure the resistance of temperature of MOTOR.

b- Required equipment:

Variable Resistance.

c- Test procedure:

-

- Connect +ve probe of resistor to the end of RTD Relay.

- Connect -ve probe of resistor to the end of RTD Relay.

- Adjust the resistance at certain value.

- As per relay manual check the corresponding temperature value which will meet this resistance.

- Set the trip and alarm setting into relay and check it actual.