This article is about Civil Grouting Repair Works and focusing to the engineers, technicians and supervisors. You will find lot of documents related to this article. Just navigate our website www.paktechpoint.com and find more articles. Please! Do not forget to subscribe our You tube channel also. Thanks in Advance.

Civil Grouting Repair Works

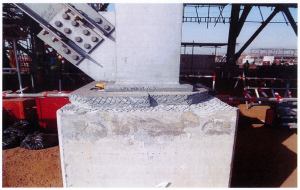

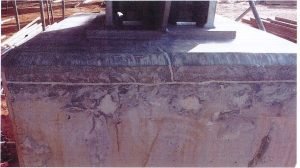

A. HOLLOW SOUND /DEBONDED CONRETE

1. CLEAN, IDENTIFY AND MARK THE PEDESTALS WITH SUSPECTED HOLLOW SOUND I DEBONDED CONCRETE.

2. AFTER IDENTIFICATION AND MARKING, REMOVE THOSE MARKED DEFECTIVE CONCRETE AREA.

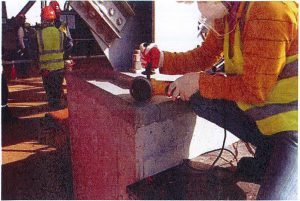

3. CUT THE MARKED AREA USING EDGE DIAMOND CUTTING TOOL.

4. CHIP OFF THE CONCRETE USING CONCRETE NAIL TO AVOID DAMAGE ON THE SURROUNDING AREAS.

5. AFTER CHIPPING OFF THE CONCRETE, CHECK AND ANALYZE THE EXTENT OF THE DETERIORATED OR DEBONDED GROUT CONCRETE.

6. CONTINUE CHIPPING OFF ALL DEFECTIVE GROUT CONCRETE UNTIL NO SIGNIFANT TRACES OF DEBONDED CONCRETE IS VISUALIZED.

7. REPLACE THE CHIPPED OFF DETERIORATED CONCRETE WITH A NEW CONCRETE ISL (MASTERFLOW 526). APPLICATION PROCEDURE SHALL BE DONE AS PER MANUFACTURER’S RECOMMENDATION.

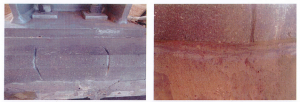

B. CRACKS

1. CLEAN AND IDENTIFY THE SURFACE CRACKS AND WIDENED IT TO A WIDTH OF 5mm TO 10mm TO CHECK THE DEPTH OF ITS DEFECT.

2. IF THE DEPTH OF THE DEFECT IS LESS THAN 25mm, USE NITOMORTAR TC2000 TO SEAL THE CRACKS. FOLLOW THE MANUFACTURER’S RECOMMENDATION ON THE APPLICATION OF THE REPAIR MATERIAL AS PER TECHNICAL DATA SHEET.

3. ANY RIDGES LEFT BY THE TROWEL CAN BE BRUSHED OUT WHILE THE MATERIAL IS STILL WET OR GROUND DOWN WITH SAND PAPER AFTER DRYING OF THE EPOXY MATERIAL.

Please read also: Civil Concrete Paving Work – CIVIL