In electrical maintenance, foresight is the key to preventing catastrophic failures and ensuring safety. To unveil concealed issues within insulation systems, engineers and technicians often employ Megger insulation testers, particularly in multi-voltage testing scenarios.

In this comprehensive guide, we delve into the art of multi-voltage insulation testing. By applying DC voltages slightly exceeding the rated AC voltage of the equipment under examination, these tests can reveal latent insulation weaknesses without causing damage. We explore the practical application of this technique, the role of prescribed DC voltages, and the importance of meticulous observation.

Discover how recent advancements in insulation testing have paved the way for higher DC voltages without compromising safety. Learn how to harness the power of the ohmmeter method, which offers reproducible results compared to the complexity of multiple voltage choices. Through informative illustrations and explanations, we demystify the process of detecting changes in insulation stability and identifying non-linear conditions that may signify impending issues.

Join us on this journey into the world of multi-voltage Megger insulation testing, where meticulous observation and innovative techniques uncover hidden insights and enhance electrical equipment reliability. Whether you’re a seasoned professional or a newcomer to the field, this guide equips you with valuable knowledge to elevate your electrical maintenance practices.

Multi-Voltage Insulation Testing

In the world of electrical maintenance, foresight and precision are the keys to preventing disasters. One powerful technique that has emerged in recent years is multi-voltage insulation testing, which involves applying DC voltages slightly higher than the rated AC voltage of the equipment under scrutiny. This method has proven invaluable in detecting latent insulation weaknesses without causing any harm.

Let’s break down the steps for effective multi-voltage insulation testing, using an industrial or traction motor in the 300- to 1000-volt range as our case study:

- Start with a one-minute Megger instrument test at 500 volts, serving as your baseline for comparison.

- After thorough cleaning, conduct a second 500-volt test to assess the cleaning’s effectiveness.

- If the insulation resistance value is below par or if the 60-second/30-second resistance ratio isn’t greater than one at this point, consider a drying operation before raising the test voltage. To decide, compare the 1000-volt test results with those at 500 volts. If the 1000-volt test significantly lags behind the 500-volt one, drying is likely needed. If they’re roughly the same, you can delay the drying decision.

- Perform a Megger instrument test at 2500 volts. If there’s no substantial difference between the 500- and 2500-volt results, the motor’s insulation is likely in good shape. However, a significant difference suggests a need for more thorough reconditioning. If the insulation fails the 2500-volt test after steps 1, 2, and 3, it’s probable that the motor would fail in service, even with reconditioning based solely on low-voltage tests.

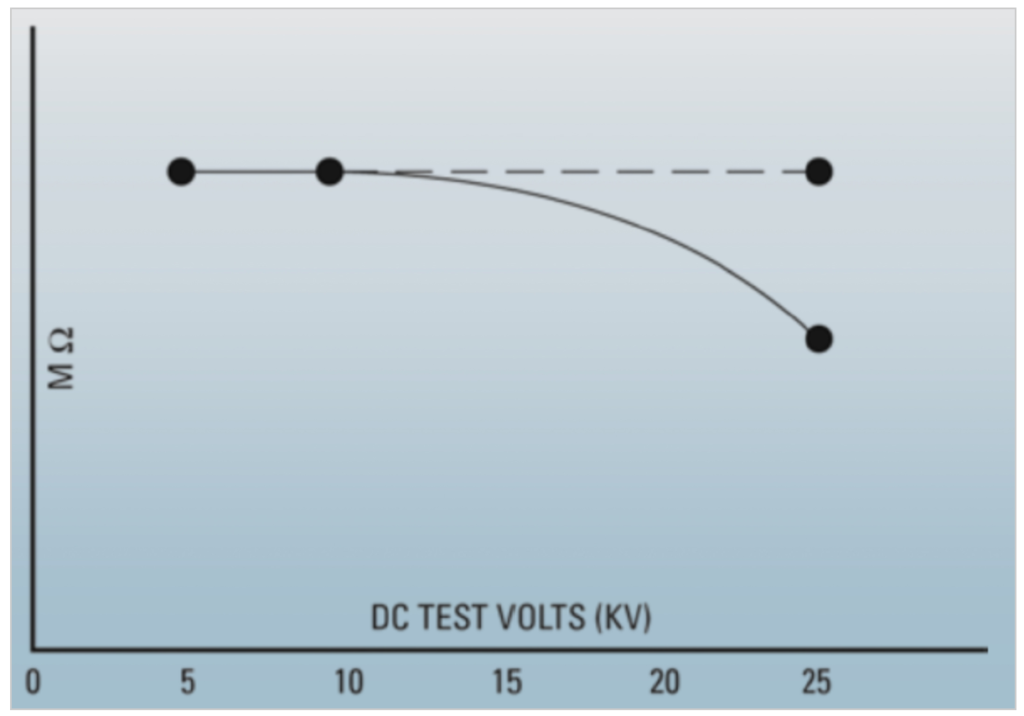

Beyond detecting insulation weaknesses, the multi-voltage method can identify excessive moisture in equipment rated at voltages equal to or greater than the highest voltage from your Megger instrument. Even though the instrument’s highest voltage doesn’t exceed the insulation’s rating, a two-voltage test can reveal moisture presence. Typically, a lower insulation resistance at the higher DC test voltage indicates moisture, with the applied voltages in a 1-to-5 ratio. A 25% change in insulation resistance with this voltage ratio often points to excessive moisture.

This method doesn’t rely on dielectric absorption but rather relates to the Evershed Effect. Like time-resistance measurements, multi-voltage insulation testing shines when done periodically or on a scheduled basis.

In summary, multi-voltage insulation testing is a valuable tool in your electrical maintenance arsenal. By following these steps and leveraging this technique, you can uncover hidden issues, assess insulation stability, and ensure the reliability of your equipment. Whether you’re an experienced professional or new to the field, this guide empowers you with knowledge to elevate your maintenance practices.

Related Articles:

What is Good insulation?

What Makes Insulation Go Bad?

How Insulation Resistance is Measured.

How to Interpret Resistance Readings.

Factors Affecting Insulation Resistance Readings.

Types of Insulation Resistance Tests.

Test Voltage vs. Equipment Rating.

AC Testing vs. DC.

Use of DC Dielectric Test Set.

Tests During Drying out of Equipment.

Effect of Temperature on insulation Resistance.

Effects of humidity.

Preparation of Apparatus to test.

Safety Precautions.

Connections for testing insulation resistance of electrical equipment.

Additional Notes About using A Megger Insulation Tester.

Interpretation-Minimum Values.

Minimum Values for Insulation Resistance.

Step-Voltage Method.

Use of a Guard Terminal.

Outdoor Oil Circuit Breaker.