Humidity, the measure of moisture content in the air, plays a crucial role in our daily lives and a wide range of industries. To accurately assess and control humidity levels, scientists and engineers have developed a fascinating instrument known as the hygrometer.

In this comprehensive technical guide, we explain into the invention, construction, working principles, types, applications, and advancements of hygrometers.

What is Hygrometer?

A hygrometer is a instrument used to measure the humidity or moisture content in the air or gas. It is an essential tool in various industries, research fields, and everyday applications where accurate humidity measurement is crucial. Hygrometers help monitor and control humidity levels, which can impact processes, product quality, comfort, and even human health.

1. Invention of the Hygrometer: Unveiling the Origins

The history of the hygrometer dates back to ancient times when philosophers and scholars pondered over the relationship between humidity and atmospheric conditions. However, it was the polymath Leonardo da Vinci who made significant contributions by conceptualizing a hygrometer based on the contraction and expansion of air due to moisture changes. Subsequently, inventors and scientists like Francesco Folli, Horace-Bénédict de Saussure, and John Frederic Daniell refined and developed various types of hygrometers.

2. Construction and Working Principle of Hygrometers

A hygrometer comprises essential components such as a sensing element, a mechanism to measure the changes, and a display system. The sensing element interacts with the surrounding air to quantify the moisture content. As humidity changes, the sensing element responds in a predictable manner, allowing the hygrometer to provide accurate readings.

3. Types of Hygrometers

Hygrometers come in diverse forms, each utilizing distinct principles:

| Hygrometer Type | Principle | Working Mechanism | Accuracy | Applications |

|---|---|---|---|---|

| Psychrometer | Evaporative cooling | Dry and wet bulb thermometers | Moderate | Weather stations, HVAC systems, meteorology |

| Hair Hygrometer | Hair length changes | Tensioned hair strands with lever mechanism | Limited | General humidity measurement, historical applications |

| Dew Point Hygrometer | Condensation on a cooled surface | Chilled mirror equilibrium | High | Industrial processes, meteorology, humidity-sensitive environments |

| Capacitive Hygrometer | Dielectric constant changes | Changes in capacitance between conductive plates | High | HVAC systems, industrial processes, consumer electronics |

| Electrical Hygrometer | Electrical resistance changes | Variation in resistance of hygroscopic material | Moderate to High | Laboratory settings, industrial processes, environmental monitoring |

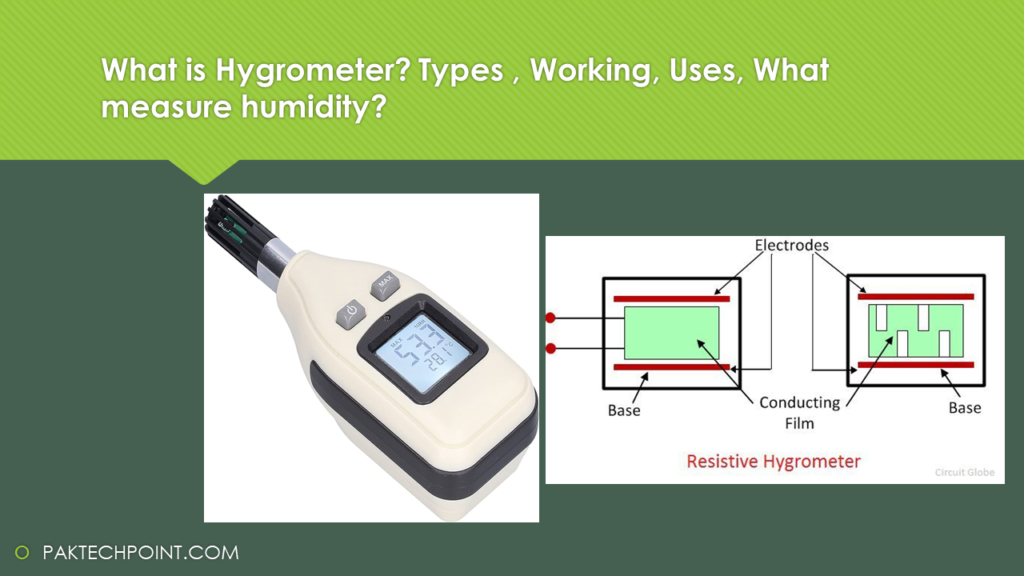

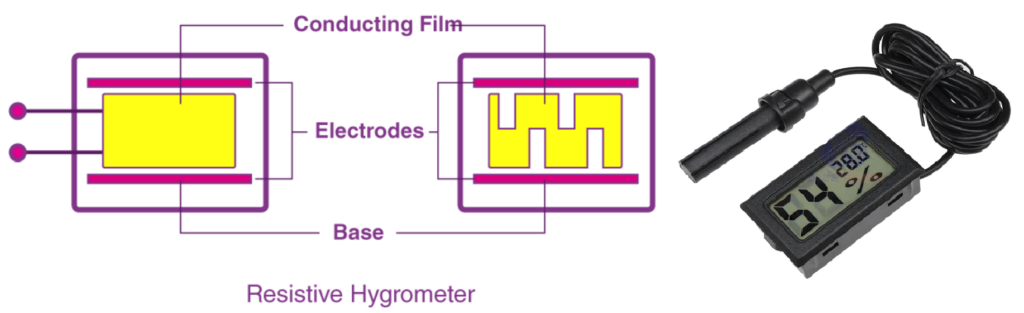

1. Electrical Hygrometers: Sensing Resistance Changes

Electrical hygrometers employ the remarkable property of certain materials to undergo changes in electrical resistance when exposed to humidity variations. How electrical hygrometers work, especially the distinction between resistive and capacitive types. These hygrometers indeed rely on changes in electrical properties to measure humidity accurately.

By analyzing the variations in electrical resistance or capacitance of specific materials, they provide valuable insights into the moisture content of the environment. This technology allows for precise and reliable humidity measurements in various applications, including industrial processes, laboratory settings, and environmental monitoring.

Two common approaches are used:

- Lithium Chloride Thin Layer: In this method, a thin layer of lithium chloride is integrated into the hygrometer’s design. Lithium chloride has a hygroscopic nature, meaning it absorbs moisture from the surrounding air. As it absorbs water molecules, the electrical resistance of the lithium chloride layer changes. By measuring this resistance alteration, the hygrometer deduces the humidity level.

- Semiconductor Device: Another electrical hygrometer variant employs a semiconductor device as the sensing element. Semiconductors exhibit altered electrical conductance in response to humidity shifts. This conductance modification is used to establish a correlation between humidity and electrical properties, enabling the hygrometer to provide humidity readings.

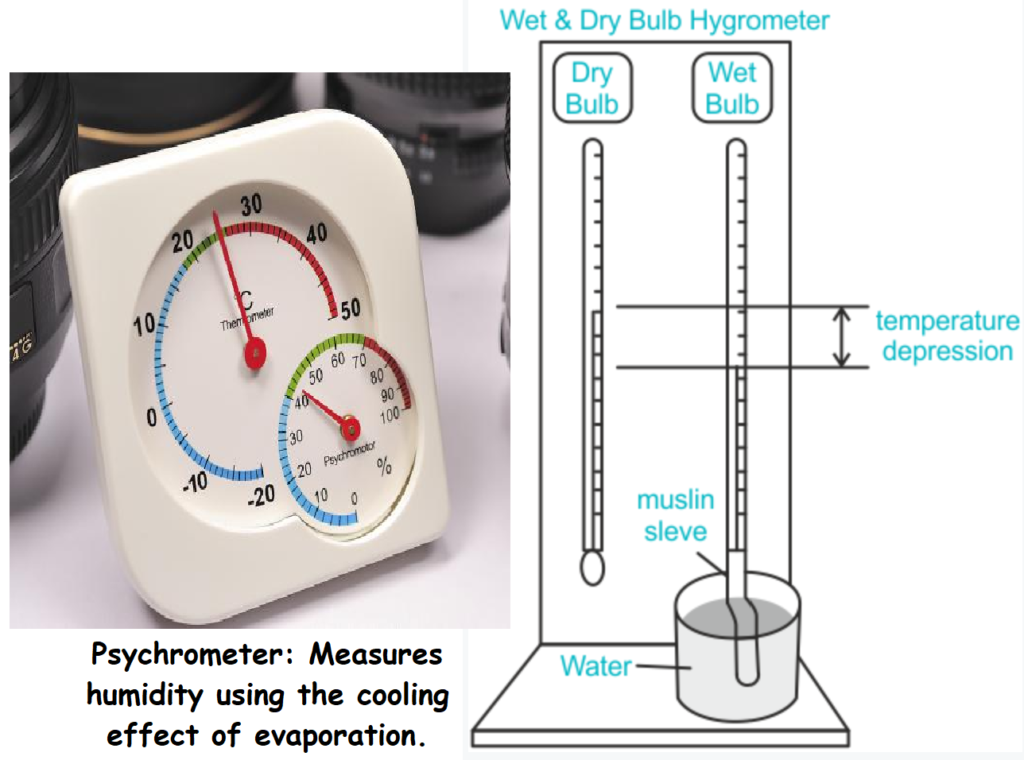

2. Psychrometer: Measures humidity using the cooling effect of evaporation.

A psychrometer is a specific type of hygrometer used to measure the relative humidity in the air. It consists of two thermometers, one being a wet-bulb thermometer and the other a dry-bulb thermometer. The dry-bulb thermometer measures the ambient air temperature, while the wet-bulb thermometer measures the temperature when a wet cloth or wick is placed around its bulb and air is circulated around it.

The principle behind a psychrometer is based on the cooling effect of evaporation. As water evaporates from the wet cloth around the wet-bulb thermometer, it absorbs heat from the surrounding air, causing the wet-bulb temperature to drop. The drier the air, the more water will evaporate, leading to a greater temperature difference between the dry-bulb and wet-bulb readings. This temperature difference is used to calculate the relative humidity.

Psychrometers are widely used in meteorology, HVAC (Heating, Ventilation, and Air Conditioning) systems, and other applications where accurate measurement of relative humidity is required. They provide a simple and effective way to determine humidity levels by comparing the dry and wet-bulb temperatures and using psychrometric charts or equations to derive the relative humidity value.

3. Hair Hygrometer or Mechanical Hygrometers: Organic Responses to Humidity

Utilizes the expansion and contraction of human or animal hair.

Mechanical hygrometers ingeniously rely on the expansion and contraction properties of certain organic materials to gauge humidity levels. Notably, substances like goldbeater’s skin (ox gut) and human hair are commonly used in this mechanism. When exposed to varying humidity conditions, these organic elements undergo changes in their dimensions.

Consider the classic example of a mechanical hygrometer equipped with a hair element. As humidity levels fluctuate, the hair strand responds by either expanding or contracting. This physical transformation of the hair element is translated into motion through a mechanical linkage system. A spring, often interconnected with the hair element, reacts to its movement, ultimately causing the needle on the dial to shift accordingly.

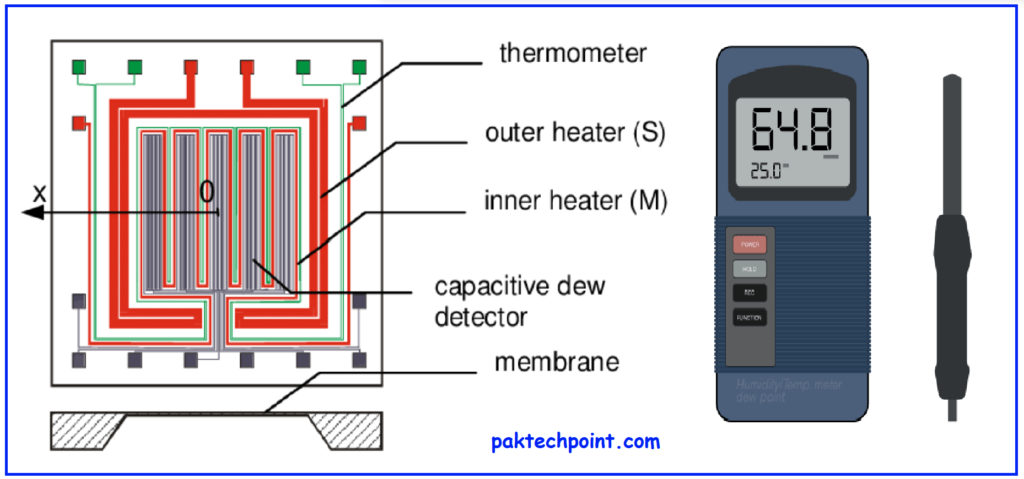

4. Dew Point Hygrometer: Determines humidity by detecting the temperature at which dew forms.

A dew point hygrometer, also known as a chilled mirror hygrometer, is an advanced instrument used to measure the dew point temperature of a gas or air mixture. This measurement is crucial in understanding the moisture content of the air, as the dew point temperature is the point at which the air becomes saturated and moisture starts to condense into dew or frost.

The principle behind a dew point hygrometer involves cooling a surface, often a mirror, until dew or frost forms on it. By monitoring the temperature at which this condensation occurs, the dew point temperature can be accurately determined. The process is controlled using electronic feedback mechanisms that ensure a dynamic equilibrium between the evaporation and condensation of moisture on the mirror.

Dew point hygrometers offer exceptional accuracy and precision in humidity measurement. They are commonly used in industrial and scientific applications where precise humidity control is essential. These hygrometers are particularly valuable in processes such as drying, air conditioning, and environmental monitoring, where maintaining specific humidity levels is crucial for optimal operation.

5. Capacitive Hygrometer: Measures humidity by assessing changes in capacitance.

A capacitive hygrometer, also known as a capacitive humidity sensor, is a type of hygrometer that measures humidity by utilizing changes in the electrical capacitance of a sensitive material in response to changes in humidity levels. This type of hygrometer is widely used due to its accuracy, compact size, and relatively low cost.

The working principle of a capacitive hygrometer is based on the fact that the dielectric constant of a material changes with the amount of moisture it absorbs. The sensor consists of two conductive plates with a moisture-absorbing material, often a polymer or ceramic, placed between them. As humidity levels change, the material absorbs or releases moisture, leading to changes in its dielectric constant and, consequently, changes in the capacitance between the plates.

The sensor is connected to a measurement circuit that detects the capacitance changes and converts them into humidity readings. These readings can be displayed on a digital screen or transmitted to other devices for analysis and control.

4. How Hygrometer Works in Instrumentation and Control Engineering?

This word derived from hydrogen. This is mostly used in Hydrogen generation system to detect the moisture quantity of hydrogen after hydrogen generation. The basic concept of moister detection is to use aluminium oxide moisture sensor in its construction. When water molecules passes through the aluminium oxide structure it absorbed and effects the electrical capacitance of the material.

Thus amount of water absorbed is related to the electrical impedance of the sensor. Generally in instrumentation and control system uses 4-20 mA current according to its range i.e -100 to 0 degree C dew point. This is normally interlocked with hydrogen generators when value reaches to set point, generator will shut down.

5. Advantages and Disadvantages of Hygrometers

Advantages:

- Provide valuable information for health, comfort, and industrial processes.

- Play a critical role in meteorology, agriculture, and material stability.

- Assist in preventing mold growth, preserving artifacts, and optimizing industrial processes.

Disadvantages:

- Some types may require calibration and maintenance.

- Accuracy can be affected by external factors like temperature changes.

6. Applications of Hygrometers

Hygrometers find applications in various fields:

- Meteorology: Monitoring weather conditions and predicting precipitation.

- Agriculture: Maintaining optimal conditions for plant growth and crop storage.

- Industrial Processes: Ensuring product quality, preventing moisture-related issues, and controlling drying processes.

- HVAC Systems: Regulating indoor air quality and comfort.

- Museums and Archives: Preserving historical artifacts and documents.

7. Modern Advancements in Hygrometer Technology

Advancements in technology have led to the development of advanced and modern hygrometers:

- Digital Hygrometers: Provide accurate and real-time readings with digital displays.

- Wireless Hygrometers: Transmit data wirelessly for remote monitoring and control.

- Microelectromechanical Systems (MEMS) Hygrometers: Offer miniaturization and integration capabilities.

Technical FAQs about Hygrometers

How do different types of hygrometers handle varying temperature conditions?

What is the impact of altitude on hygrometer readings?

How do hygrometers account for non-linear humidity responses in certain materials?

What calibration procedures are necessary to maintain hygrometer accuracy?

How do hygrometers handle humidity gradients within an environment?

Conclusion:

Hygrometers, with their diverse types and evolving technologies, remain invaluable instruments in understanding and controlling humidity. From the ancient concepts of Leonardo da Vinci to the cutting-edge MEMS hygrometers of today, these devices have transformed how we perceive and manage moisture in our environment. As technology continues to advance, hygrometers will play an even more critical role in industries, research, and our everyday lives.

Read Related Articles: