Geotextile fabrics have revolutionized civil engineering and environmental conservation alike. Used widely for applications including erosion control, soil stabilization and drainage improvement – geotextile fabrics made of permeable polyester or polypropylene geosynthetics provide enhanced soil interaction while remaining stable and durable – meeting multiple challenges encountered during construction projects or restoration efforts.

Geotextile fabrics have become an effective solution to control erosion and ground stabilization, with applications including road construction, drainage improvement and landscape preservation. Geotextile fabrics offer sustainable erosion control and stabilization solutions. Ultimately they play a crucial role in keeping our planet greener by improving soil health.

- With their superior strength and permeability, geotextile fabrics have quickly become indispensable components in today’s civil engineering projects.

- The geotextile fabric market is experiencing impressive expansion, driven by technological innovations and increased emphasis on sustainable construction practices.

- Geotextile fabrics provide a practical yet sustainable solution, meeting various ground-related challenges while supporting environmental preservation.

![What is Geotextile Fabrics? Technical Guide [PDF]](https://paktechpoint.com/wp-content/uploads/2023/09/image-421.png)

This article presents an overview of geotextile fabrics’ significance and applications within construction and environmental preservation, with particular attention paid to sustainability and innovation. With their increasing popularity and rapid technological advances enhancing their potential use in civil engineering and environmental preservation. Their future looks bright.

An Introduction to Geotextile Fabrics

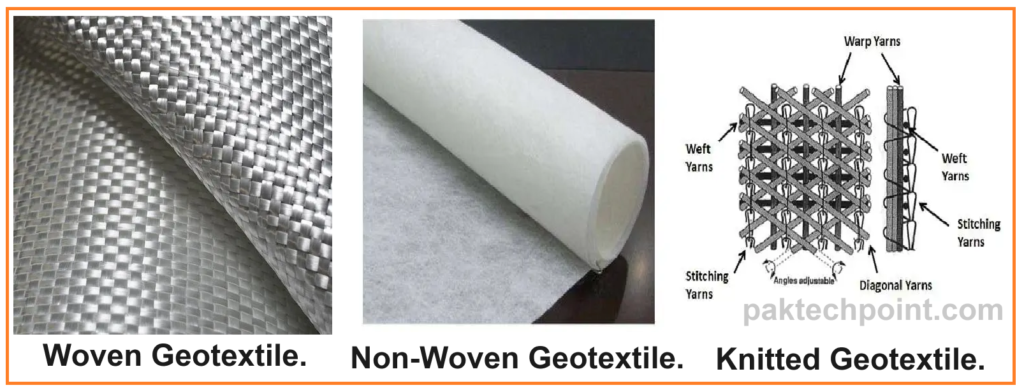

Geotextile fabrics come in three basic forms: woven, non-woven and knitted; each form serving its own specific function. Woven geotextiles are known for their high strength and are commonly employed in road construction and soil stabilization applications; non-woven geotextiles with high permeability can provide drainage/filtration functionality while knitted geotextiles offer deformability / adaptability features for use in areas that require deformation / adjustability / deformability applications.

Construction of Geotextile fabrics

Geotextile fabrics are specialty fabrics constructed primarily of materials such as polypropylene and polyester that have high water permeability properties. They can be divided into woven and non-woven varieties with each having distinct production methods and applications, depending on their intended use.

1. Non-Woven Geotextile Fabrics

Non-woven geotextile fabrics consist of fibers or filaments bonded together randomly to form an extremely robust and flexible fabric, suitable for various applications.

2. Woven Geotextile Fabrics

Woven geotextile fabrics are produced through interweaving yarns, fibers, filaments, strips or other elements at right angles along their length and crosswise dimensions using textile processes. This intertwining method, commonly referred to as the “simple pattern” method, results in a flat structure. Woven geotextile fabrics are widely used in construction due to their biaxial resistance as well as high resistance with minimal deformation by virtue of the structure and features of strips used during production – making them an excellent option for reinforcing roads, slopes walls and foundations.

Category of Woven Geotextile Fabrics:

Single Filament Geotextile Fabrics:

These are produced from meshing together one long length textile fiber, providing uniform strength and stability across their entirety.

Multiple Filament Geotextile Fabrics: These geotextile fabrics are created from meshes of multiple long textile fibers woven together for increased strength and versatility.

Short Fiber Yarn Geotextile Fabrics:

These geotextile fabrics are composed of an interlaced mesh of short cut fibers ranging in length (up to 15cm) for flexibility and adaptability across applications.

Erosion Control Is Key for Success

Erosion control is one of the main applications of geotextile fabrics. They play an essential part in protecting soil layers and limiting loss due to water flow, helping ensure landscape sustainability while mitigating environmental degradation. Geotextiles act as protective barriers by absorbing energy from running water or wind flow – effectively reducing soil erosion on slopes or embankments.

Soil Stabilization and Reinforcement

Geotextile fabrics are an invaluable asset when it comes to soil stabilization. By segregating various soil types and evenly disbursing loads, geotextiles prevent intermixing of distinct layers and increase bearing capacity of the soil – something essential in road, railway and foundation construction where ground stability must be paramount.

Filtration and Drainage Solutions

Geotextile fabrics are an outstanding way of effectively draining and filtering soil. Their quick expulsion of excess water from soil, thus decreasing hydrostatic pressure and improving soil stability. Their permeable nature allows water to pass while simultaneously restricting movement of particles – fulfilling both functions simultaneously for increased infrastructure longevity.

Sustainability and Environmental Benefits

Geotextiles are an example of sustainable engineering solutions. Their ability to mitigate soil erosion and promote efficient drainage contributes significantly to environmental preservation, while using geotextiles reduces resource consumption such as aggregates. Plus, using geotextiles enhances lifespan and durability of structures thereby decreasing repairs/reconstructions costs, thus cutting carbon emissions associated with construction activities.

Installation and Maintenance Services

Installing geotextile fabrics requires careful attention to ensure optimal performance and longevity. Fabric should be installed smoothly without wrinkles and securely fastened in place to avoid movement. Maintenance costs tend to be minimal, consisting mostly of periodic inspections for damages or obstructions in drainage systems and regular checks to make sure everything works optimally.

Market Development and Projections for Growth

Geotextile fabric market growth has experienced exponential expansion due to an increasing demand in construction and environmental applications. Continuous innovations and advancements in geotextile technologies are expanding their uses further and making geotextile fabrics indispensable components in modern building and environmental conservation projects. Furthermore, growing awareness about environmentally friendly construction materials further promotes their adoption as essential elements in future civil engineering endeavors.

Geotextile fabrics represent an impressive feat of innovation in civil engineering, seamlessly merging functionality and sustainability. Their versatile applications range from erosion control and soil stabilization, drainage and filtration systems as well as environmental management to erosion prevention and control. Geotextiles’ combination of strength, permeability, and durability makes them the go-to solution for numerous ground-related challenges, ensuring structural stability while contributing to environmental preservation. With increasing awareness regarding sustainable construction practices, geotextile fabric markets look set for significant expansion; making geotextiles a vital element in civil engineering as well as ecological restoration projects.

Geotextile Fabric: Uses and Applications

Geotextile fabrics feature biaxial resistance, providing strength in both directions of production. This characteristic makes woven geotextile fabrics ideal for construction projects where high resistance and low deformation are key features of success.