Ship propulsion refers to the mechanism or system used to generate thrust and propel a ship through water. It is a critical aspect of ship design and operation, influencing the vessel’s speed, maneuverability, fuel efficiency, and overall performance. Ship propulsion systems can vary significantly based on factors such as the vessel’s size, purpose, operating environment, and technological advancements.

What is Ship Propulsion?

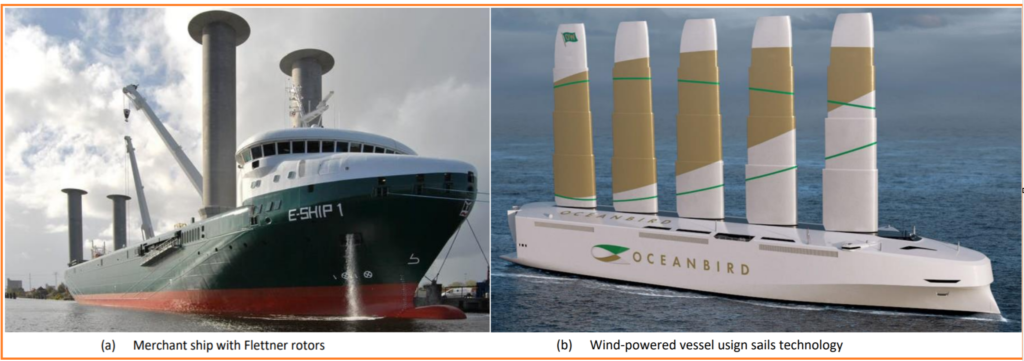

Ship propulsion depends upon generating thrust by causing a stream of water (and sometimes air) in the opposite direction of the ship’s motion. Various methods can be used, including wind power, such as flettner rotors or sails, to propel the ship forward. Marine propellers, the most common propulsion devices, are typically made from corrosion-resistant materials like aluminum-stainless steel alloys, nickel alloys, aluminum-bronze alloys, which offer high strength and lighter weight.

Propellers Types

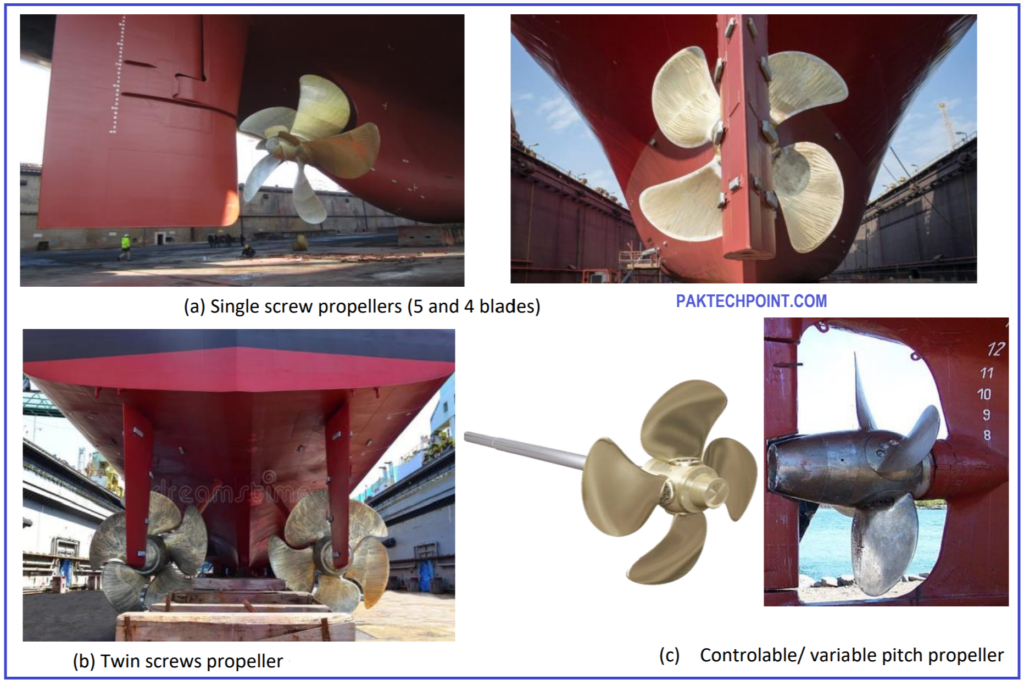

Propellers can be classified based on the number of blades or blade pitch. Screw propellers, the famous type, feature helicoidal blades rotating through the water. This rotation creates a pressure difference between the forward and rear surfaces of the blades, generating thrust to propel the ship forward. Modern ships, especially passenger vessels and LNG carriers, often employ twin propellers, using two propellers to produce thrust.

Most marine screw propellers have fixed blades, producing consistent thrust and torque at a given RPM. However, controllable or variable pitch propellers offer blade adjustment capability, allowing for varied thrust and torque output at the same RPM by adjusting the pressure difference between the blades. This flexibility in blade adjustment can optimize performance and efficiency in different operating conditions.

Propeller classification based on number of blades

| Propeller Type | Technical Characteristics |

|---|---|

| 3 Blade | – Low manufacturing cost – Material: aluminum alloy – Excellent high-speed performance – Better acceleration compared to other types – Less efficient at low speeds |

| 4 Blade | – Higher manufacturing cost than 3 blade propellers – Material: stainless steel alloys – Good strength and durability – Effective low-speed handling and performance – Provides good holding power in rough seas – Offers good fuel economy |

| 5 or 6 Blade | – Higher manufacturing cost – Minimal vibration – Excellent holding power in rough seas – Low pressure field over the propeller decreases |

Propeller classification based on pitch

| Propeller Type | Technical Characteristics | Advantages | Limitations |

|---|---|---|---|

| Fixed Pitch | – Blades permanently attached to the hub | – Reliable operation | – Fitted in ships with limited maneuverability demands |

| Variable Pitch | – Blade rotation and pitch variation possible | – Good maneuverability and efficiency | – High risk for oil pollution due to potential hydraulic oil leaks |