1 Introduction

2 References

3 Definition

4 Background

5 Benefits

6 Drawbacks

7 Do Your Homework Before

What is Adjustable Frequency Drive and Application

1. Adjustable Frequency Drive Introduction

The main purpose of this article is to help the candidate end user of an AFD to develop systematic approach to determine if the application qualifies for an AFD. On the other side, the advantages and disadvantages of adding power electronics system to the network is presented to complete the familiarity of the user with VFD utilization. This will provide a basic understanding of how AFDs work.

2. Adjustable Frequency Drive References

Industry Codes and Standards

Institute of Electrical and Electronics Engineers

IEEE 519 – 1992 Recommended Practices and Requirements of Harmonic Control in Electrical Power Systems

IEEE 1566 – 2005 Performance of Adjustable Speed AC Drives Rated 375 kW and Larger

International Electrotechnical Commission

IEC 146-1 -1 Semiconductor Convertors General Requirements and Line Commutated Convertors Specifications of Basic Requirements

IEC 61800-3 EMC requirements and specific test methods

IEC 61800-4 Adjustable Speed Electrical Power Drive Systems General Requirements – Rating Specifications for AC Power Drive Systems above 1 000 V a.c. and not exceeding 35 kV

IEC 61 800-5-1 Safety Requirements -Electrical, Thermal an Energy

IEC 61800-6 Guide for Determination of Types of Load Duty and Corresponding Current Ratings

National Electrical Manufacturers Association

NEMA 250-2003 NEMA Enclosure Types

ICS 7-2000 Industrial Control and Systems: Adjustable-Speed Drives

ICS 7.1-2000 Safety Standards for Construction and Guide for Selection, Installation, and Operation of Adjustable-Speed Drive Systems

3. Adjustable Frequency Drive Definition

AC: Alternating Current

AFD: (Adjustable Frequency Drive) a solid-state device that controls the speed of an AC motor by controlling the voltage and frequency of the power source of the motor.

Rectifier: A full-wave, solid-state rectifier converts three-phase frequency power from a standard or higher utility supply to either fixed or adjustable DC voltage. The system may include transformers if higher supply voltages are used.

Inverter: Switch the rectified DC on and off using electronics switches, and produce a current and voltage waveforms at the desired new frequency. The amount of distortion depends on the design of the inverter and filter.

Control: An electronic circuit receives feedback information from the driven motor and adjusts the output voltage or frequency to the selected values. Usually, the output voltage is regulated to produce a constant ratio of voltage to frequency (V/Hz). Controllers may incorporate many complex control functions.

IGBT: Insulated Gate Bipolar Transistor

GTO: Gate Turn Off Transistor

IGCT: Integrated Gate-commutated Thyristor

MOSFET: Metal–oxide–semiconductor/Field-effect transistor

RPM: Revolutions per minute

F: Power Supply Frequency

P: number of pair poles

KW: Kilowatts

KVAR: Kilovolts Amps Reactive

PFC: Power Factor Correction is technique used to increase power factor

PF: Power Factor is the ratio of KW/KVA

FLA: Full Load Amps

KVA: Kilovolt Amps

DC: Direct Current

AFE: Active front end AFD uses IGBTs in the rectifier circuit instead of diodes can operate in a four quadrant.

CIV: Corona inception voltage is the lowest voltage at which continuous corona occurs as the applied voltage is gradually increased.

4. Adjustable Frequency Drive Background

Most motor applications in the plants, oil and gas industry such as pumps, fans and compressor do not require a constant load. They are usually sized for a peak load that may account for only fraction of the hours of operation. Throttling valves, recycling valves vanes or

dampers may be employed to control capacity of a constant speed pump, fan or compressor.

These devices increase the head, thereby forcing the fan or pump to ride the curve to a point where it produces less flow (Figure 2). Power consumption is the product of head and flow. Throttling the output increases head, but reduces flow, and may provides some energy savings but not significantly. Another way to control the flow is to use adjustable frequency drive to control the motor speed.

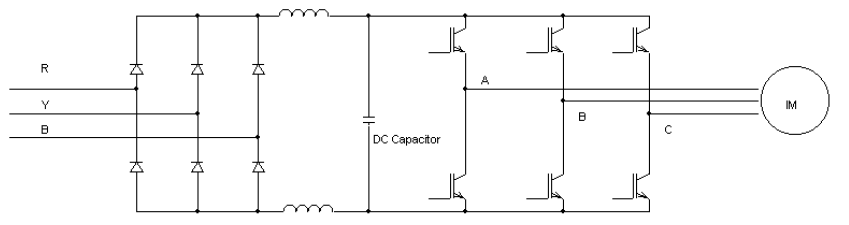

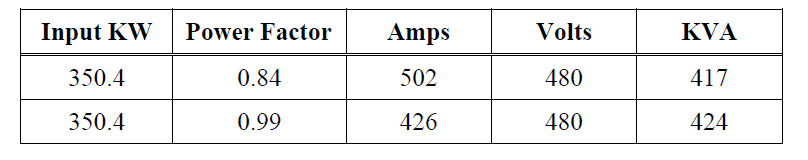

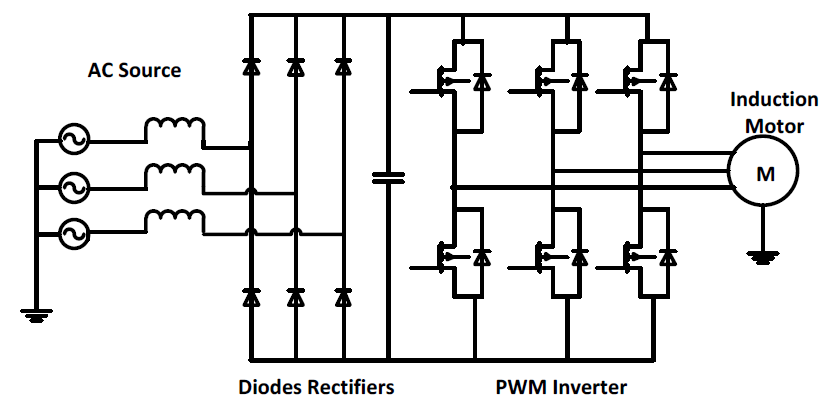

Figure 1 – Simple three phase constant voltage source inverter (Source-AFD-Load)

Adjustable frequency consists of two main blocks: rectifier and inverter with inductive or capacitive link in between (See Figure 1). The rectifier rectifies the AC power through a set of controlled (SCR, GTO..) or uncontrolled (diodes) devices. The inverter section invert the DC power into AC with the desired frequency using switching devices (IGBT, MOSFET, IGCT..) with the appropriate control scheme.

Constant voltage AFDs works on the concept of V/HZ curve where the voltage and power change in linear while the torque remains at the maximum value at the zero speed (zero frequency). When the voltage and frequency reach the rated values any change in speed will happen by changing the frequency (constant power period).

The torque will drop after that point and the motor will not provide the enough torque to rotate the load at higher speeds.

Another type of the AFD is known as Constant Current AF. While in the AFD in Figure 1 shows a Constant Voltage AFD through fixing the DC Common Bus, the Constant Current AFD use duple coils at DC Common Bus as shown in Figure 2. In constant current drives, a large inductor is placed between the input rectifier and the output bridge, so the current delivered is nearly constant.

Figure 3 – Simple three phase constant current AFD (Source-AFD-Load)

As seen in formula [1], the motor speed is directly proportional to the frequency of the supplied voltage; therefore changing the frequency of the AC supplied voltage control the speed of the motor and regulates the flow based on the required by the process.

RPM = (F x 120) / P [1]

Figure 4 – Pump and System Curves

5. Adjustable Frequency Drive Benefits

The advantages of using VFD are myriad; energy savings, low inrush, high power factor and low KVA will be the focus in the following subparagraphs:

5.1 Energy Savings

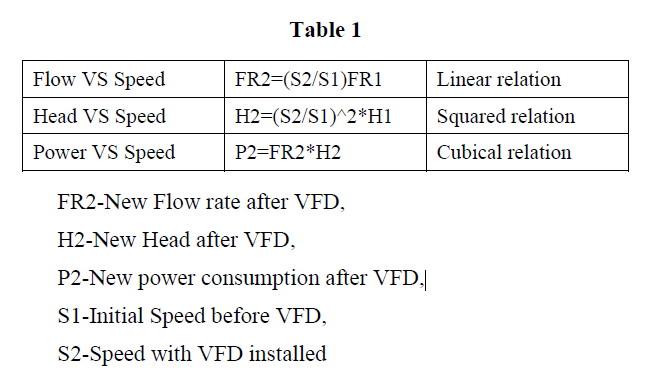

Let us take the fan as an example, the ideal fan (affinity) laws describe how speed affects flow, head and power consumption (See Table 1).

When using speed to reduce capacity, both the head and flow are reduced in a cubical relationship providing maximum energy savings and allow process control in an efficient manner.

5.2 Low Inrush Motor Starting

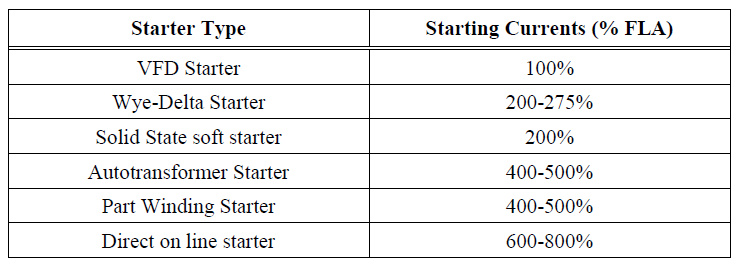

It is common for AC induction motors to draw 6 to 8 times their full load current when they are started direct on line. When large amounts of current are drawn on the transformers, a voltage drop can occur, adversely affecting other equipments on the same network. Some sensitive applications may even trip off line. Wye-delta, part winding, autotransformer, and solid state starters are often used to reduce inrush during motor starting. All of these starters deliver power to the motor at a constant frequency and therefore must limit the current by controlling the voltage supplied to the motor. The amount of voltage reduction possible is limited because the motor needs enough voltage to generate torque to accelerate. With maximum allowable voltage reduction, the motor will still draw two to four times the full load amps (FLA) during starting (See Table 2).

Unlike all other types of starters, the AFD uses frequency to limit the power and current delivered to the motor. The VFD will start the motor by delivering power at a low frequency. At this low frequency, the motor does not require a high level of current. The VFD incrementally increases the frequency and motor speed until the desired speed is met.

Table 2 – Comparison of Starter Types Based on Inrush

5.3 Unlimited Number of Starts

Because of a controlled start and low inrush when using VFD, unlimited number of starts and stops without harmful effects become feasible. This feature may be required for maintenance and testing.

5.4 High Power Factor

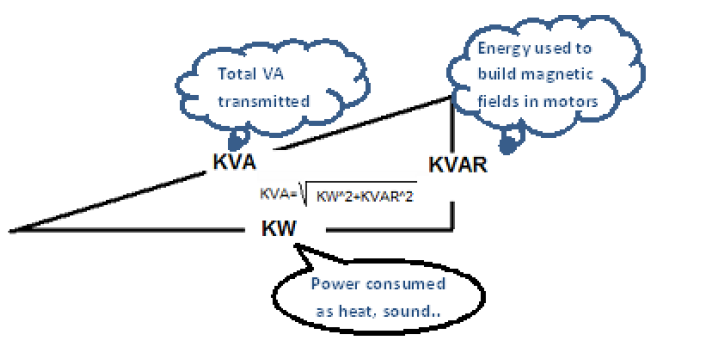

Power converted to heat, motion… etc., is called real power and is measured in kilowatts (kW). Power that charges capacitors or builds magnetic fields is called reactive power and is measured in Kilovolts Amps Reactive (KVAR). The vector sum of the kW and the KVAR is the Total Power (energy) and is measured in Kilovolt Amperes (KVA) (Figure 3). Power factor is the ratio of kW/KVA. Motors draw reactive current to support their magnetic fields in order to cause rotation. Excessive reactive current is undesirable because it creates additional resistance losses and can require the use of larger transformers and wires. Decreasing reactive current will increase power factor.

Figure 5 – Power Triangle

Typical AC motors may have a full load power factor (PF) ranging from 0.84 to 0.88. As the motor load is reduced, the power factor becomes lower. Power factor correction (PFC) capacitors can be added to reduce the reactive current measured upstream of the capacitors and increase the measured power factor. To prevent damage to the motor, power factor correction capacitors should not exceed the motor manufacturer’s recommendations. In most cases, this results in maximum corrected values of 0.90 to 0.95.

The VFDs include capacitors in the DC bus that perform the same function and maintain high power factor on the line side of the VFD. This eliminates the need to add power factor correction equipment to the motor or use expensive capacitor banks.

5.5 Low Full Load KVA

Total Power (KVA) is often the limiting factor in the amount of energy that can be transmitted through an electrical device or system. If the KVA required by equipment can be reduced during periods of peak demand, it will help alleviate voltage sags, brownouts, and power outages. This can lower electrical system cost and free up KVA capacity on existing systems.

When VFDs with active front ends (AFE) are used, the generator size can approach an ideal 1:1 ratio of kW/KVA because the power factor is near unity (1.0) and the harmonics produced by the VFD are extremely low. Lower KVA also benefits utilities. When the power factor is higher, more power (kW) can be delivered through the same transmission equipment.

5.6 Eliminating the need of gearbox

The gearbox normally used to speed up or speed down the shaft of the driven equipment. In the application of speeding up the driven equipment, the AFD is capable to generate frequencies from 2 – 400 Hz. In application of gas compression, the compressor is running at ranges from 5000-8000 RPM using a gearbox to speed up the compressor speed over the 3600 RPM. This requirement is achievable using a combination of high-speed motor and an AFD. Closer look should be taken at the motor integrity and harmonics effects in the case.

In lower speed applications, the drive could eliminate the gear box when it used to work below the 1800 RPM. Some precautions should be taken into the consideration such as lower cooling and the high vibration frequency.

5.7 Other Advantages

The following advantages might be gained and realized after installing the AFD as speed adjustment tool:

5.7.1 More controllability

5.7.2 Faster response to process requirements

5.7.3 More accurate adjustment

5.7.4 Possibility to utilize the setup for more applications (one pipeline could be used to ship more than one product)

5.7.5 Less mechanical stress on motor and driven equipment

5.7.6 Less pollution comparing to steam speed variation techniques with more availability

5.7.7 Less noise when compared to other speed adjustment tools like steam turbines or gas turbines.

6. Adjustable Frequency Drive Drawbacks

While VFD provides an excellent way to control a motor’s speed and gain energy savings, it generates some phenomenon that can affect the power such as noise, reduce the life of the cable, and even disrupt operation of other equipment in some cases. Understanding this phenomenon explains why conducting a study before making the decision helps maintain reliable, long-term operation. Below are the main impacts that can affect the system when using VFD.

6.1 Cable

The connection between the motor and the VFD is critical. Careful selection insures that it does not become the “weakest link” in the system. Reflected waves caused by a cable-to-motor impedance mismatch are prevalent in all VFD applications. The magnitude of the problem depends on the length of the cable, the rise-time of the PWM (pulse width modulated) carrier wave, the voltage of the VFD, and the magnitude of the impedance difference between the motor and cable.

Under the right conditions, a pulse from the VFD can add to a pulse reflected back from the motor to result in a doubling of voltage level, which could damage the cable. Because cable length is mostly determined by the layout of the application, while rise times vary with the VFD output semiconductor and the voltage of the VFD is determined by the application, the impedance of the cable relative to the motor will be the primary parameter that needs to be looked at. The characteristic impedance of a cable is calculated using the following formula, where:

Zc = SQRT(L/C) [2]

Zc = characteristic impedance, L = cable inductance, and C = cable capacitance

Cables with higher impedance tend to result in lower peak motor terminal voltages. Lower voltages across the motor terminals translate into the cable being exposed to lower voltages, increasing its life expectancy. In addition, this reduces the likelihood of either the cable or the motor reaching its corona inception voltage (CIV).

Corona discharge produces very high temperatures. If the insulation system of the cable is a thermoplastic material such as PVC, the phenomenon can cause premature cable burn-out or a short circuit due to a gradual, localized melting of the insulation. Furthermore, thermoplastic insulations should not be used for VFD applications instead “thermoset” insulation cables such as of CROSS-LINKED POLYETHYLENE (XLPE), a material with high impulse voltage breakdown levels is a recommended one.

Another cable related issue is the noise radiated from a VFD cable. It is proportional to the amount of varying electric current within it. As cable lengths grow, so does the magnitude of reflected voltage. This transient over voltage, combined with the high amplitudes of current associated with VFDs, creates a significant source of radiated noise. By shielding the VFD cable, the noise can be controlled. For this reason, unshielded cables in conduit are not a recommended method for connecting VFDs to motors. Finally, a round, symmetrical cable generates more uniform electrical characteristics in the cable gives the best electrical performance and resistance to harmful effects.

6.2 Shaft Grounding

The fast fall and rise times of the inverter devices and the varying widths of modulated pulses (PWM) do not allow for complete cancellation of the voltage waveforms like in a 60 HZ application. This imbalance result of the generation of a common mode voltage that occurs between the inverter and the ground. This common mode voltage in turn generates induced shaft voltages in the motor. These voltage transients also interact with the circuit impedance of the inverter, the three-phase power supply cables and the relative impedance of the motor to generate high frequency common mode currents (CMC). The latter seek the path of least impedance to ground while returning to the inverter. In many cases, these paths can become the shafts and bearings of the motor and all of its connected equipment. If the CMC become sufficient enough in magnitude, early deterioration of the bearings can result causing premature mechanical failure to the motor and connected equipment. For this reason appropriate shaft grounding should be carefully considered.

6.3 Structural Resonance

Resonance conditions can cause excessive vibration levels, which in turn are potentially harmful to equipment and environment. Pumps, their support structure, and piping are subject to a variety of potential structural vibration problems (resonance conditions). Fixed-speed applications often miss these potential resonance situations because the common excitation harmonics due to running speed, vane passing frequency, plunger frequency, etc., do not coincide with the structural natural frequencies. For VSD applications, the excitation frequencies become variable and the likelihood of encountering a resonance condition within the continuous operating speed range is greatly increased. For this reason, a pump intended for variable speed operation should be tested at multiple speed range.

6.4 Harmonics

Harmonics are unwanted currents that are multiples of the fundamental line frequency (60 Hz). Variable frequency drives is becoming common in the oil industry, especially for large gas compressors and oil pumps. The use of rectifiers and inverters for variable speed motor drives cause harmonics to flow in the power lines. Harmonics can impact electrical systems in a number of ways: Conductor insulation overheating, higher temperature rise in transformers and motors resulting in shorter life and instrumentation signal interference. Technology offers numerous techniques to mitigate this phenomenon. Detailed analysis should be performed before choosing the appropriate one and IEEE 519 – 1992 limit recommendations should be fulfilled.

6.5 Other Disadvantages

Installation of AFD has some other drawbacks that need to be studied and monitored carefully. These drawbacks include:

6.5.1 Needs careful maintenance programs

6.5.2 AFD might stop the process in case of failure if the bypass is not available

6.5.3 Minimal contamination could cause flashover or component failure

6.5.4 Air cooled AFDs increase the sound noise inside the substation

6.5.5 Water cooled AFDs require thorough water treatment schedule

6.5.6 Not designed for outdoor installation

6.5.7 Limited cable length between AFD and the motor

6.5.8 Air cooled AFDs necessitate increment in HVAC sizing.

7. Do Your Homework Before

Because of the energy saving campaign, ozone depletion consideration and other reasons, the use of VFD is being pushed without technical and economical investigation. This behavior is leading to an inefficient scenario and troublesome situations. In order to avoid the aforementioned, one has to conduct detailed analysis to insure the legitimacy of using AFD. A systematic approach detailing the required steps to be followed has been developed in the following sections:

a. Complete understanding: Develop a complete understanding of the process requirements and the machine to which you are connecting the AFD.

b. Load Profile: Develop a load/time profile for the targeted system. This step is critical for calculating accurate energy savings. For each component, list annual hours, all flow conditions.

c. Real Speed Change Need: Determine why the load operation needs to be changed. The need for the VFD should be based on the ability to change the load’s speed as required. In those applications where only one speed change is required, a VFD may not be necessary and soft starter may be adequate.

d. Engineering Specifications: Obtain complete engineering specifications and performance curves for the targeted machines.

e. High static pressure (head) consideration: Applications in which a minimum pressure must be maintained may not be suitable candidates for a VFD. For example, if high pressure is required even at low flow, it is may be not possible to significantly reduce pump speed.

f. Retrofitting/Motor Duty Consideration: General-purpose induction motors are not designed for repetitive voltage overshoots that exceed certain voltage and overshoots become likely. Repeated voltage stresses can lead to insulation breakdown and premature motor failure. To use an AFD with an existing general-purpose motor, additional filtering and transient protection should be considered. NEMA definite-purpose motors rated “Inverter Duty” are recommended for use with VFDs. These motors can withstand repetitive voltage spikes that are 3.1 times the rated RMS voltage and may be used when retrofitting is required.

g. Is it worth it: Smaller motors are not as efficient as larger ones, so the gain due to the VFD is not significant; however, since large motors consume much more power, even small increases in efficiency, over the life of the motor, can lead to appreciable savings.

h. Sizing: If more than one motor is driven, will they start up sequentially or simultaneously? Calculate the total peak currents of all motor loads under the worst operating conditions. Size your VFD according to this maximum current requirement under peak torque demands. The potential for damaging reflected waves is especially high when multiple motors are run from a single AFD.

i. Overheating concern: Cooling often depends on motor speed, such as with totally enclosed fan-cooled (TEFC) motors. Therefore, a motor should not be operated at less than 30% speed without additional cooling.

j. Environment consideration: AFD should be installed indoor (cooled, protected area). SAES does not support an outdoor installation, however in a situation of an old installation outdoor; the AFD should at least have the appropriate enclosure rating. Please refer to NEMA enclosure type “250-2003” for enclosure selection.

k. Harmonics and RFI Consideration: Additional line filtering is often required to reduce the propagation of harmonics and radio frequency interference (RFI) to other equipment. Short connection between the motor and the AFD help minimize RFI propagation. When connection is longer than 15 meters (50 feet), reactive filters are recommended. Motor leads should also be enclosed in a rigid conduit to reduce RFI.

l. Power Factor: If power factor corrections capacitors present on the motor loads to be connected to AFD, then, when these are switched, they typically generate power disturbances, and AFDs can be negatively impacted. Isolation transformers or line reactors may be necessary.

m. Ride through capability: If the power source occasionally switches to standby generators while the AFD is operating, this might happen, for example, when loads are switched to standby generators during a power outage. Some drives can handle a brief power outage (ride through), others cannot. Ride through is an optional feature to be requested.

n. Rotation of the direction: The phase sequence of the supply connection to the AFD does not affect the rotation direction of the drive. Changing the phase sequence between the drive and the motor will change the direction of rotation of the motor. Be sure to verify rotation of the drive to the equipment. Some equipment may be damaged if rotation is reversed. If a bypass contactor is used with a AFD, be sure that the rotation direction is correct during bypass operation.

o. Dynamic breaking consideration: If required, load breaking is usually accomplished in a power resistor across the DC bus to dump excess energy. This resistor is optional and available when requested.

p. Service Disconnect: Service disconnects at motor loads are very often used for maintenance purposes. Normally, removing a load from an AFD while operating does not pose a problem for the AFD. On the other hand, introducing a load to a AFD by closing a motor disconnect while the VFD is operational can be fatal to the AFD. When a motor is started at full voltage, as would happen in this case, high currents are generated, usually about six times the full load amps of the motor current. The VFD would see these high currents as being well beyond its capabilities and would go into a protective trip or fail altogether. A simple solution for this condition is to interlock the VFD run permissive circuit with the service disconnects via an auxiliary contact at the service disconnect. When the disconnect switch is closed, a permissive run signal restarts the VFD at low voltage and frequency.

r. Monitoring requirement: If downtimes and event logging are critical for the application for fault analysis and equipment history, monitoring tool may be required.

s. Bypass switch: Bypass switch is very helpful when fault occur and during maintenance. If the system is very critical and operation cannot afford to shut the device off then, bypass is the solution. Some units may go on automatic bypass mode during VFD fault to prevent load disruption.

t. Spinning or Coasting Load at start up: This is very often the case with fan applications. When a VFD is first started, it begins to operate at a low frequency and voltage and gradually ramps up to a preset speed. If the load is already in motion, it will be out of sync with the VFD. The VFD will attempt to pull the motor down to the lower frequency, which may require high current levels, usually causing an over current trip. Because of this, VFD manufacturers offer drives with an option for synchronization with a spinning load; this VFD ramps at a different frequency.

u. Reputation: A manufacturer that has a good ‘track record’ should eventually be chosen. Well established technology should be used unless there is a very good reason to try out some new technology.