What is FCAW?

FCAW stands for Flux-Cored Arc Welding. It is a welding process that uses a continuously fed consumable tubular electrode containing a flux core. FCAW is similar to Gas Metal Arc Welding (GMAW), also known as MIG (Metal Inert Gas) welding, in that it uses a wire electrode to create the weld. However, there are some key differences between the two processes:

- Flux Core: In FCAW, the electrode contains a flux core that generates a shielding gas when it reacts with the heat of the arc. This shielding gas protects the weld pool from atmospheric contamination, just like the externally supplied shielding gas in GMAW.

- No External Gas: Unlike GMAW, which requires an external shielding gas (typically argon, CO2, or a mixture), FCAW is known as a “self-shielded” process because it generates its shielding gas internally from the flux core. This makes FCAW more suitable for outdoor welding where wind can disperse an externally supplied shielding gas.

- Versatility: FCAW can be used for both semi-automatic and automatic welding processes, and it is suitable for a wide range of materials, including carbon steel, low-alloy steel, stainless steel, and some non-ferrous metals.

- Deep Penetration: Flux-cored welding typically provides deeper penetration into the base material compared to some other welding processes, making it suitable for thicker materials.

- High Deposition Rates: FCAW can achieve high deposition rates, making it a productive welding process in industrial applications.

- Versatility in Positions: FCAW is versatile in terms of welding positions. It can be used for flat, horizontal, vertical, and overhead welding, making it suitable for a variety of welding projects.

FCAW is commonly used in industries such as construction, shipbuilding, pipeline welding, and manufacturing, where its ability to handle thicker materials, outdoor conditions, and high deposition rates is advantageous. However, like any welding process, it requires proper training and safety precautions to ensure quality welds and the safety of the welder.

1. FCAW Scope

This article establishes general practices for Flux Cored Arc Welding (FCAW).

2. FCAW References

Reference is made in this article to the following documents.

American Society of Mechanical Engineers (ASME)

Section IX Welding and Brazing Qualifications

American Welding Society (AWS)

AWS A5.20 – Specification for Stainless Steel Electrodes for Flux Cored Arc Welding.

AWS A5.22 – Specification for Stainless Steel Electrodes for Flux Cored Arc Welding and Rods for Gas Tungsten Arc Welding.

AWS A5.29 – Specification for Low Alloy Steel Electrodes for Flux Cored Arc Welding.

Flux Cored Arc Welding (FCAW) Complete Guide

FCAW process produces the fusion of metals by heating them with an arc between a continuously fed filler metal (consumable) electrode and the work. Shielding is provided by a flux contained within the tubular electrode and may or may not be supplemented by an externally shielding gas.

Fundamentals. The feature that distinguishes FCAW process from other arc welding processes is the enclosure of fluxing ingredients within a continuously fed electrode. Both the particular operating characteristics of the process and the resulting weld properties are controlled by the flux being encased in a metallic sheath.

Safety. Follow safe practices prescribed.

One significant safety factor in FCAW is the amount of smoke and fume produced. This process produces more smoke than shielded metal arc welding process with covered electrode; however, much more weld metal is deposited per unit of arc time. Proper positioning of the welder’s head and the use of a curved front welding hood will greatly reduce the smoke/fume that will reach the breathing zone.

The use of forced ventilation devices is usually necessary as much for general shop atmosphere as for the welder’s well being. Several manufacturers have also introduced welding guns equipped with fume extractors built into them. The exhausting nozzle encircles the gun nozzle and is ducted to an exhaust pump and filter cannister. The disadvantage is the weight that is added to the gun.

FCAW Features

The heat generated by the arc melts the surface of the base metal and the end of the electrode. Shielding is obtained from the disintegration of ingredients contained within the flux cored electrode. Additional shielding may be added by gas supplied through the nozzle to the arc area.

In addition to producing a shielding gas, the flux ingredients provide deoxidizers, ionizer, scavenging agents, and frequently alloying elements. These also form a glass-like slag, which, being lighter than the weld pool, floats on the surface and acts as a protection blanket. The electrode is fed into the arc automatically from a spool or coil. The arc is thus maintained automatically and travel can be manual or by a carriage.

Applications. Higher productivity is the chief appeal of FCAW for many applications. With the advent of the ‘metal core’ electrode types, there is little slag to remove and deposition rates are further improved. The process is used to produce weldments conforming to the ASME Code.

With the availability of small diameter electrode 0.889/1.143 mm (0.035/0.045 in) piping applications down to 76.2 mm (3 in) diameter and open root weld preparation are realistic, but high skill is required. Out-of-position welding is possible with 15.2 mm (0.60 in) diameter and smaller electrodes.

Equipment. In semiautomatic welding, the equipment is generally the same as that used for GMAW processes, see SES W07-F01. If large diameter wire [3.2 mm ( 1/8 in) diameter] is contemplated, then a power supply of 500-650 amperes may be necessary for maximum productivity. Gun-to-cable assemblies generally are much heavier than those used in GMAW applications. The controls shall be capable of voltage adjustment in increments of one volt.

4. Gasless Electrode

Self Shielding Electrodes. Electrodes have been developed that are self shielding for many applications. One disadvantage is the amount of spatter produced.

5. Shielding Gases

CO2. Carbon dioxide is the most widely used shielding gas for FCAW process on mild steel. Low cost and deep weld penetration are the two major advantages of this gas. A disadvantage is the amount of spatter produced.

Gas Mixtures. Gas mixtures used in this process combine the separate advantages of two or more gases. The higher the percentage of inert gas in mixtures with CO2 or oxygen, the higher will be the transfer efficiencies of the deoxidizers contained in the wire core. The mixture commonly used is 75 percent argon, 25 percent CO2. . When welding with this mixture, the arc transfer mode approaches a spray type. When using CO2 , the transfer is globular.

The argon-CO2 mixture is mainly used for out-of-position welding because of better arc characteristics and hence greater welder appeal. The selection of shielding gas is critical in FCAW and the electrode manufacturer or his literature shall be consulted prior to making a selection. The mechanical properties of the weld deposit depend to a large degree upon the shielding gas.

6. Process Control.

A constant voltage power source of the proper size is used to melt the electrode at the rate that maintains the preset output voltage (or arc length). Welding current is proportional to electrode feed rate for a specific electrode extension. If other welding variables are held constant:

a. lncreasing current increases electrode deposition rate.

b. Increasing current increases penetration.

c. Increasing current excessively produces convex weld beads with poor appearance.

d. Reducing current too much produces large droplet transfer and excessive spatter.

e. Reducing current too much can result in nitrogen pickup and result in porosity in the weld bead when welding with self shielded flux cored electrode.

Stick Out. Normally the contact tip to work distance (the stick out plus arc length) is 19 to 38.1 mm and for gasless wire 19 to 95.3 mm. As electrode extension increases, welding current will decrease and vice versa. Too long a stick out produces an unstable arc with excessive spatter. Too short an extension will cause excessive arc length at a particular voltage setting.

7. Electrodes.

Mild steel FCAW electrodes are classified on the basis of whether or not carbon dioxide is required as a separate shielding gas, the type of current, their usability for welding position and number of weld passes, and the chemical composition and as-welded mechanical properties of deposited weld metal. Electrodes are designed to produce weld metals having specified chemical compositions and mechanical properties when the welding and testing are done to the specification requirements. Electrodes are produced in standard sizes ranging from 0.89 to 3.97 mm (0.035 to 5/32 in) diameter. Special sizes may also be available. Weld properties may vary appreciably depending upon: electrode size, welding amperage, plate thickness, joint geometry, preheat and interpass temperatures, surface conditions, base metal composition and admixture with the deposited metal, and shielding gas. Many electrodes are designed primarily for welding in the flat and horizontal positions.

They may also be suitable for use in other positions if the proper choice of welding current and electrode diameter are made. Selected electrodes with diameters below 2.38 mm (3 / 32 in) and welding currents on the low side of the manufacturer’s recommended range may be used for out-of-position welding.

8. Description and Intended Use of flux Cored Electrodes.

There are many different classifications of flux cored electrodes in AWS A5.20. The suffix in each classification (1 to 14, G and GS), indicates a general grouping of electrodes that contain similar flux or core components and which have similar usability characteristics. Some classifications are listed as being suitable for multiple and single-pass welding, while others are said to be suitable only for single-pass welding. An electrode that is suitable for multiple-pass welding may also be suitable for a single pass welding.

The user shall understand that the classifications listed for single-pass welding are more highly deoxidizing and can be used on base metals that have some rust or mill scale. When these electrodes are used for more than a single pass, these deoxidizers can build up as alloying elements and act to increase the strength and hardness of the weld metal.

These same effects will also be observed when an electrode classified with CO2 shielding gas is used with a less reactive gas (argon or combinations containing argon, for example).

EXXT-1 and EXXT-1M Classifications.

Electrodes of the EXXT-1 group are classified with CO2 shielding gas.

However, other gas mixtures (for example argon-CO2 ) may be used to improve the arc characteristics, especially for out-of-position work, when recommended by the manufacturer. Increasing the amount of argon in the argon-CO2 mixture will increase the manganese and silicon contents in the weld metal. The increase in manganese and silicon will increase the yield and tensile strengths and may affect impact properties.

Electrodes of the EXXT-1M group are classified with 75-80% argon/balance CO2 shielding gas. Their use with argon/CO2 shielding gas mixtures having reduced amounts of argon or with CO2 shielding gas may result in some deterioration of arc characteristics and out-of-position welding characteristics. In addition, a reduction of the manganese and silicon contents in the weld will reduce yield and tensile strengths and may affect impact properties.

Both the EXXT-1 and EXXT-1M electrodes are designed for single and multiple pass welding using DCEP polarity. The larger diameters [usually 2.0 mm (5/64 in) and larger] are used for welding in the flat position and for welding fillet welds in the horizontal position (EX0T-1 and EX0T-1M). The smaller diameters [usually 1.6 mm] and smaller are generally used for welding in all positions (EX1T-1 AND EX1T-1M).

The EXXT-1 and EXXT-1M electrodes are characterized by a spray transfer, low spatter loss, flat to slightly convex bead contour, and a moderate volume of slag which completely covers the weld bead. Most electrodes of this classification have a rutile base slag and produce high deposition rates.

EXXT-2 and EXXT-2M Classifications.

Electrodes of these classifications are essentially EXXT-1 and EXXT-1M with higher manganese or silicon, or both, and are designed primarily for single-pass welding in the flat position and for welding fillet welds in the horizontal positions. The higher levels of deoxidizers in these classifications allow single-pass welding of heavily oxidized or rimmed steel.

Weld metal composition requirements are not specified for single-pass electrodes, since checking the composition ofthe undiluted weld metal will not provide an indication of the composition of a single-pass weld. These electrodes give good mechanical properties in single-pass welds.

The manganese content and the tensile strength of the weld metal of multiple-pass welds made with EXXT-2 and EXXT-2M electrodes will be high. These electrodes can be used for welding base metals which have heavier mill scale, rust, or other foreign matter that cannot be tolerated by some electrodes of the EXXT-1 or EXXT-1M classifications. The arc transfer, welding characteristics and deposition rates of these electrodes are similar to those of the EXXT-1 or EXXT-1M classifications.

EXXT-3 Classification.

Electrodes of this classification are self shielded, used on DCEP, and have a spray-type transfer. The slag system is designed to make very high welding speeds possible. The electrodes are used for single-pass welds in the flat, horizontal, and vertical (up to 20 degree incline) positions( downward progression) on sheet metal. Since these electrodes are sensitive to the effects of base-metal quenching, they are not generally recommended for the following:

(i) T or lap joints in materials thicker than 4.8 mm.

(ii) Butt, edge, or corner joints in materials thicker than 64 mm.

The electrode manufacturer shall be consulted for specific recommendations.

EXXT-4 Classification.

Electrodes of this classification are self shielded, operate on DCEP, and have a globular-type transfer. The slag system is designed to make very high deposition rates possible and to produce a weld that is very low in sulphur, which makes the weld very resistant to hot cracking. These electrodes are designed for low penetration beyond the root of the weld, enabling them to be used on joints which have been poorly fitted, and for single and multiple-pass welding.

EXXT-5 and EXXT-5M Classifications.

Electrodes of the EXXT-5 classification are designed to be used with CO2 shielding gas; however as with the EXXT-1 classification, argon-CO2 mixtures may be used to reduce spatter.

Electrodes of the EXXT-5M classification are designed for use with 75-80% argon/balance CO2 shielding gas.

Electrodes of the EX05-5 and EX0T-5M classifications are used primarily for single and multiple-pass welds in the flat position and for welding fillet welds in the horizontal position. These electrodes are characterized by a globular transfer, slightly convex bead contour, and a thin slag that may not completely cover the weld bead.

These electrodes have a lime-fluoride base slag. Weld deposits produced by these electrodes typically have impact properties and hot and cold crack resistance that are superior to those obtained with rutile base slags. The EX1T-5 and EX1T-5M electrodes, using DCEN, can be used for welding in all positions. However, the operator appeal of these electrodes is not as good as those with rutile base slags.

EXXT-6 Classification.

Electrodes of this classification are self shielded, operate on DCEP, and have a spray-type transfer. The slag system is designed to give a good low-temperature impact properties, good penetration into the root of the weld, and excellent slag removal, even in a deep groove. These electrodes are used for single and multiple-pass welding in flat and horizontal positions.

EXXT-7 Classification.

Electrodes of this classification are self shielded, operate on DCEN, and have a small droplet transfer to a spray-type transfer. The slag system is designed to allow the larger sizes to be used for high deposition rates in the horizontal and flat positions, and to allow the smaller sizes to be used for all welding positions. The electrodes are used for single- and multiple-pass welding and produce very low sulphur weld metal which is very resistant to cracking.

EXXT-8 Classification.

Electrodes of this classification are self shielded, operate on DCEN, and have a small droplet or spray-type transfer. The electrodes are suitable for all welding positions and the weld metal has very good low temperature notch toughness and crack resistance. The electrodes are used for single and multiple-pass welds.

EXXT-9 and EXXT-9M Classifications.

Electrodes of the EXXT-9 group are classified with CO2 shielding gas. However, gas mixtures of argon-CO2 are sometimes used to improve usability, especially for out-of-position applications.

Increasing the amount of argon in the argon-CO2 mixture will affect the weld metal analysis and mechanical properties of weld metal deposited by these electrodes, just as it will for weld metal deposited by EXXT-1 and EXXT-1M electrodes. Electrodes of the EXXT-9M group are classified with a 75-80% argon/balance CO2 shielding gas mixtures having reduced amounts of argon, or with CO2 shielding gas, may result in some deterioration of arc characteristics and out-of position welding characteristics.

In addition, a reduction of the manganese and silicon contents in the weld will result, which will have some effect on properties of weld metal from these electrodes, just as it will on properties of weld metal deposited by EXXT-1 and EXXT-1M electrodes.

Both the EXXT-9 and EXXT-9M electrodes are designed for single and multiple-pass welding. The larger diameters [usually 2.0 mm and larger] are used for welding in the flat position and for welding fillet welds in the horizontal position. The smaller diameters [usually 1.6 mm and smaller] are often used for welding in all positions.

The arc transfer, welding characteristics, and deposition rates of the EXXT-9 and EXXT-9M electrodes are similar to those of the EXXT-1 or EXXT-1M classifications. EXXT-9 and EXXT-9M electrodes are essentially EXXT-1 and EXXT-1M electrodes that deposit weld metal with improved impact properties.

Some electrodes in this classification require that joints be relatively clean and free of oil, excessive oxide, and scale in order that welds of radiographic quality can be obtained.

EXXT-10 Classification.

Electrodes of this classification are self shielded, operate on DCEN, and have a small droplet transfer. The electrodes are used for single-pass welds at high travel speeds on material of any thickness in the flat, horizontal, and vertical (up to 20 degree incline) positions.

EXXT-11 Classification.

Electrodes of this classification are self shielded, operate on DCEN, and have a smooth spray-type transfer. They are general purpose electrodes for single and multiple-pass welding in all positions. Their use is generally not recommended on thicknesses greater than 19 mm (in) unless preheat and interpass temperature controls are maintained. The electrode manufacturer shall be consulted for specific recommendations.

EXXT-12 and EXXT-12M Classifications.

Electrodes of these classifications are essentially EXXT-1 and EXXT-1M electrodes which have been modified to improve impact toughness and to meet the lower manganese requirements of the A-1 Analysis Group in the ASME Section IX. They, therefore, have an accompanying decrease in tensile strength and hardness. Since welding procedures influence all weld metal properties, users should check hardness on any application where a required hardness level is a requirement.

The arc transfer, welding characteristics, and deposition rates of the EXXT-12 and EXXT-12M electrodes are similar to those of the EXXT-1 and EXXT-1M classifications.

EXXT 13 Classification.

Electrodes of this classification are self shielded, operate on DCEN, and are usually welded with a short-arc transfer. The slag system is designed so that these electrodes can be used in all positions for the root pass on circumferential pipe welds. The electrodes can be used on all pipe wall thicknesses, but are only recommended for the first pass. They generally are not recommended for multiple-pass welding.

EXXT 14 Classification.

Electrodes of this classification are self shielded, operate on DCEN, and have a smooth spray-type transfer. The slag system is designed with characteristics so that these electrodes can be used to weld in all positions and also to make welds at high speed. They are used to make welds on sheet metal up to 4.8 mm thick, and often are specifically designed for galvanized, aluminized, or other coated steels, Since these welding electrodes are sensitive to the effects of base-metal quenching, they are not generally recommended for the following:

(i) T- or lap joints in materials thicker than 4.8 mm.

(ii) Butt, edge, or corner joints in materials thicker than 6.4 mm.

Consult the electrode manufacturer for specific recommendations.

EXXT-G Classifications.

This classification is for multiple-pass electrodes that are not covered by any presently defined classification. Except for chemical requirements to assure a carbon steel deposit and the tensile strength, which is specified, the requirements for this classification are not specified. They are those that are agreed to by the purchaser and the supplier.

EXXT-GS Classifications.

This classification is for single-pass electrodes that are not covered by any presently defined classification. Except for the tensile strength, which is specified, the requirements for this classification are not specified; they are agreed upon by the purchaser and the supplier.

9. Low alloy steel electrodes.

Flux cored electrodes are commercially available for welding low alloy steels. They are described and classified in AWS A5.29. The electrodes are designed to produce deposited weld metals having chemical compositions and mechanical properties similar to those produced by low alloy steel SMAW electrodes.

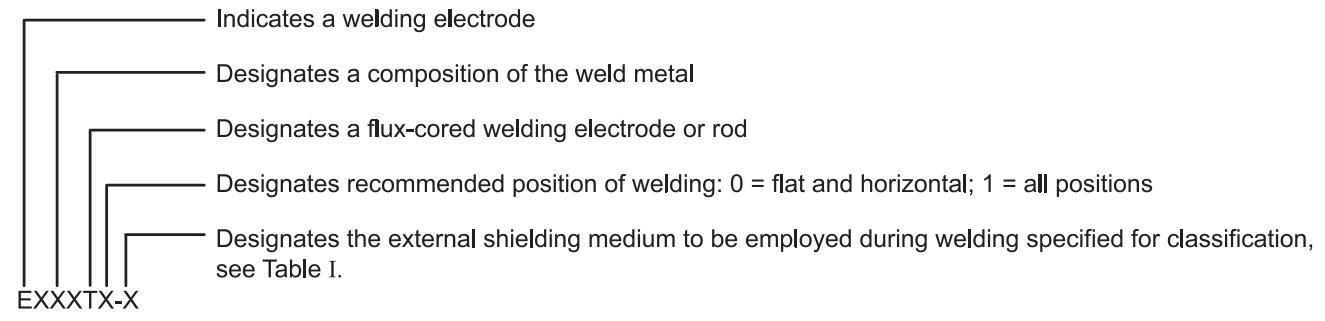

They are generally used to weld low alloy steels of similar chemical composition. Some electrode classifications are designed for welding in all positions while others are limited to flat and horizontal fillet positions only. Like the mild steel electrodes, there is an identification system used by AWS to describe the various classifications. Figure 1 illustrates the components of these designations.

4.10 AWS A5.29 lists five different classifications of low alloy steel FCAW electrodes.

Their descriptions and intended uses are summarized below.

EXXT1-X: Electrodes of the EXXT1 group are classified with CO2 shielding gas. However, gas mixtures of argon-CO2 may be used where recommended by the manufacturer to improve usability, especially for out-of-position applications.

These electrodes are designed for single- and multiple-pass welding. The EXXT1 electrodes are characterized by a spray transfer, low spatter loss, flat to slightly convex bead configuration, and a moderate volume of slag, which completely covers the weld bead.

EXXT4-X: Electrodes of the EXXT4 classification are self shielded, operate in direct-current reverse polarity, and have a globular-type transfer. The slag system is designed to give characteristics that make possible very high deposition rates and desulfurization of the weld metal to a very low level, which helps make the weld deposit very resistant to penetration. This enables them to be used on weld joints with poor fit-up and for single- and multiple-pass welding in the flat and horizontal positions.

EXXT5-X: Electrodes of the EXXT5 group are designed for use with CO2 shielding gas (argon-CO2 mixtures may be used where recommended by the manufacturer as in the EXXT1 types) for single- and multiple-pass welding in the flat position, and for horizontal fillets. Certain EXXT5 electrodes are designed to weld on DCEN with argon-CO2 mixtures for out-of-position welding. These electrodes are characterized by a globular transfer, slightly convex bead configuration, and a thin slag, which may not completely cover the weld bead. Weld deposits produced by electrodes of this group have improved impact properties and crack-resistance in comparison with the EXXT1 types.

EXXT8-X: Electrodes of the EXXT8 classification are self shielded and operate on DCEN. The slag system is designed to give characteristics that make it possible to use these electrodes for all-position welding. The slag system is also designed to produce very good low temperature impact properties in the weld metal and to desulfurize the weld metal to a very low level, which helps resist weld cracking. They are used for single- and multiple-pass welding.

11. Stainless Steel Electrodes.

The classification system of AWS A5.22 prescribes requirements for flux cored corrosion resisting chromium and chromium-nickel steel electrodes. These electrodes are classified on the basis of the chemical composition of the deposited weld metal and the shielding medium to be employed during welding.

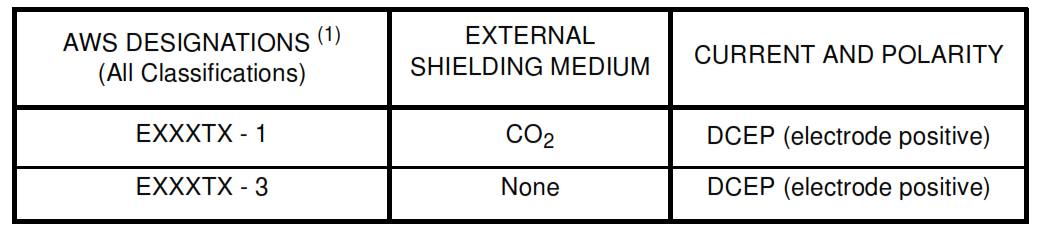

Table I identifies the shielding designations used in the classification and indicates the respective current characteristics.

Table I – Shielding Designations and Welding Current

Characteristics for Stainless Steel Flux Cored Electrodes

(1) The classifications are given in AWS A5.22. The letters ‘XXX’ stand for the chemical composition. The ‘X’ after the ‘T’ designates the position of the

operation. A ‘0’ after T indicates flat or horizontal operation. A ‘1’ after T indicates all positions operation.

11.1 With the EXXXTX-1 classifications using CO2 shielding, there is some minor loss of oxidizable elements and some increase in carbon content. With the EXXXTX-3 classifications, which are used without external shielding, there is some loss of oxidizable elements and pickup of nitrogen which may be significant. Low welding currents coupled with long arc lengths (high arc voltages) may cause excessive nitrogen pickup. Nitrogen stabilizes the austenite and therefore, may reduce the ferrite content of the weld metal.

11.2 The requirements of the EXXXTX-3 classifications are different from those of the EXXXT-1 classifications because shielding with a flux system alone is not as effective as shielding with both a flux system and a separately applied external shielding gas. The EXXXTX-3 deposits, therefore, usually have a higher nitrogen content than the EXXT-1 deposits. This means that to control the ferrite content of other weld metal, the chemical compositions of the EXXXTX-3 deposits shall have different Cr/Ni ratios than those of the EXXXTX-1 deposits.

11.3 The mechanical properties of deposited weld metal are specified for each classification. Properties include minimum tensile strength and ductility. Radiographic soundness requirements are also specified.

11.4 Although welds made with electrodes meeting the AWS specification requirements are commonly used in corrosion or heat-resisting applications, it is not practical to require electrode qualification tests for corrosion or scale resistance on welds or weld metal specimens. Special tests which are pertinent to an intended application shall be established by agreement between the electrode manufacturer and the user.

5. FCAW Inspection

The amount and type of inspection required depends upon the service conditions and hazards to personnel and property. It is the responsibility of the originator to define the inspection requirements. Inspection shall be in accordance with applicable code(s).

FIGURE 1 – Identification System for Low Alloy Steel FCAW Electrodes