ACI 210R-93 ACI Standard Erosion of Concrete in Hydraulic Structures

ACI 210R-93 ACI Standard Erosion of Concrete in Hydraulic StructuresMechanism of cavitation

Cavitation is that the formation of bubbles or cavities in an exceedingly liquid. In hydraulic structures, the liquid is water, and the cavities square measure stuffed with vapor and air. The cavities form wherever the native pressure drops to a price which will cause the water to vaporize at the prevailing fluid temperature.

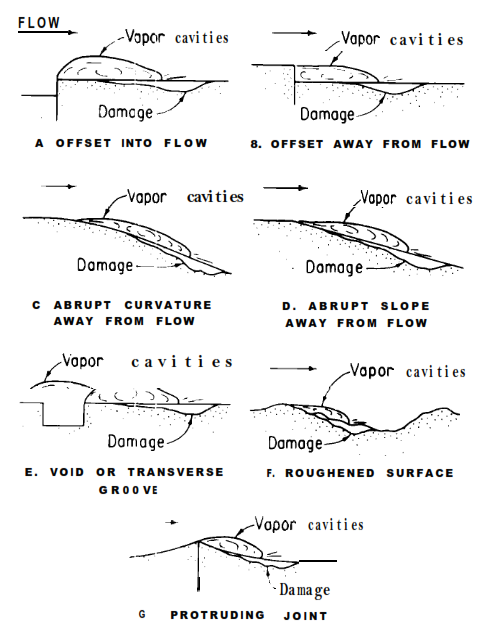

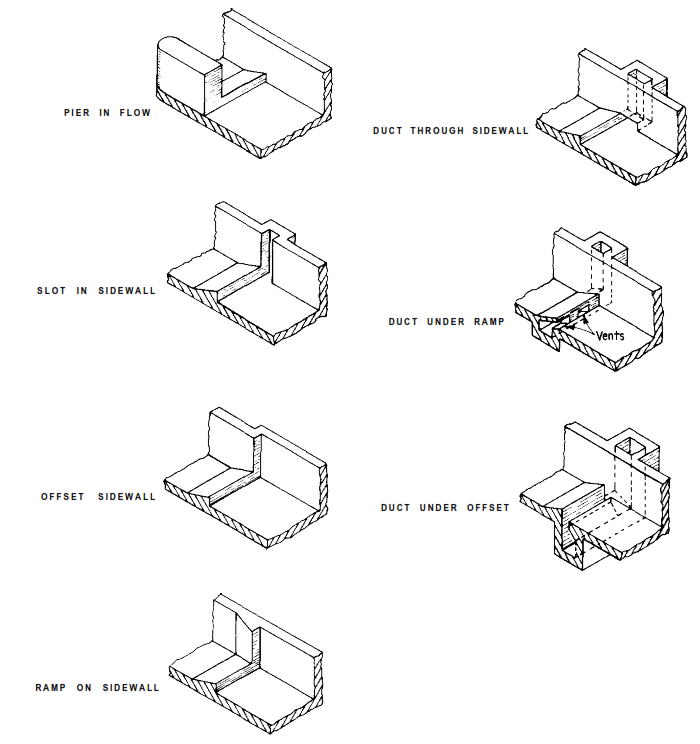

Fig. shows samples of concrete surface irregularities which can trigger formation of those cavities.

The pressure drop caused by these irregularities is usually abrupt and is caused by native high velocities and curved streamlines. Cavities usually begin to create close to curves or offsets in an exceedingly flow boundary or at the centers of vortices.

Cavitation situations at surface irregularities

Tunnel contraction

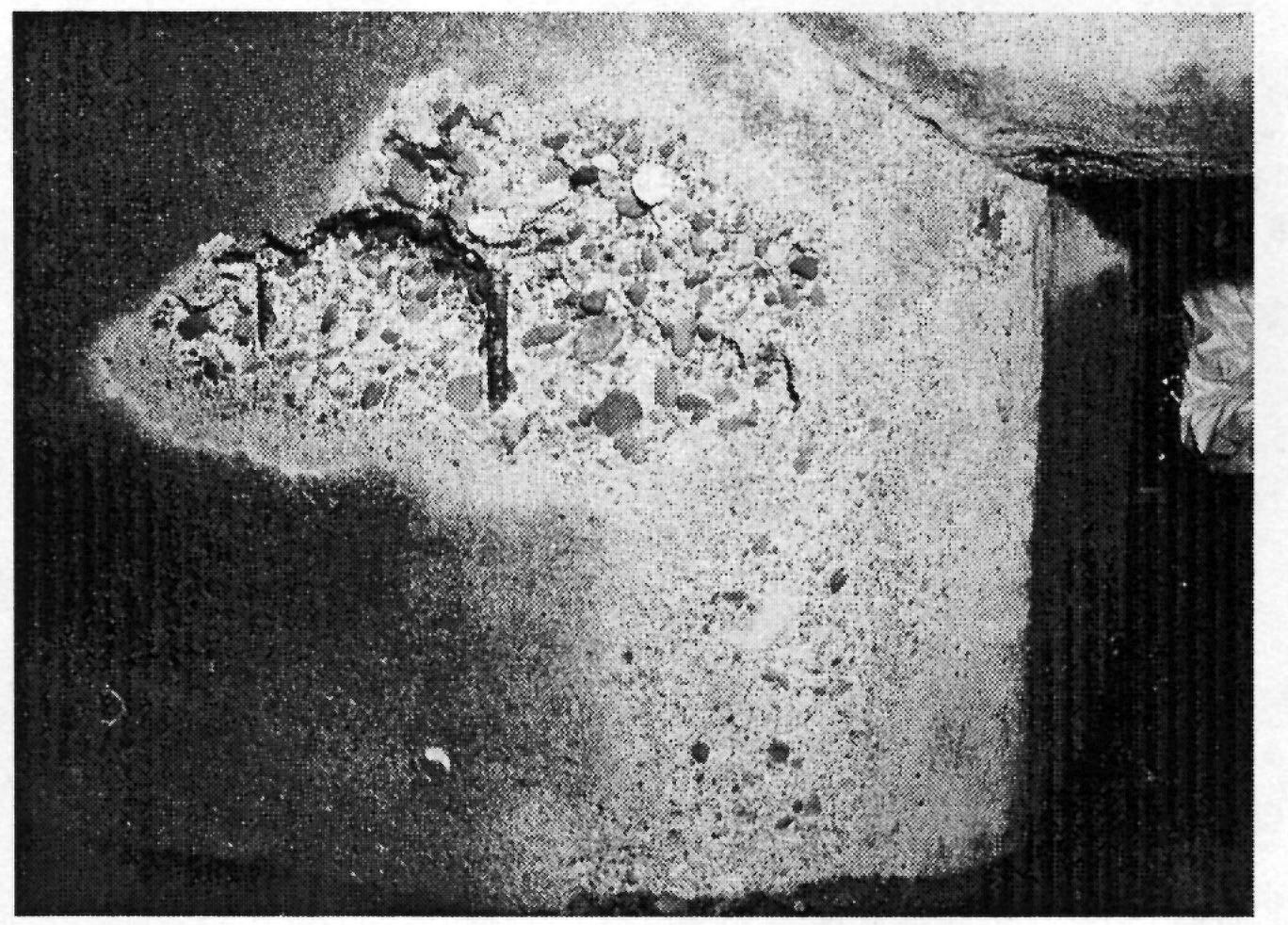

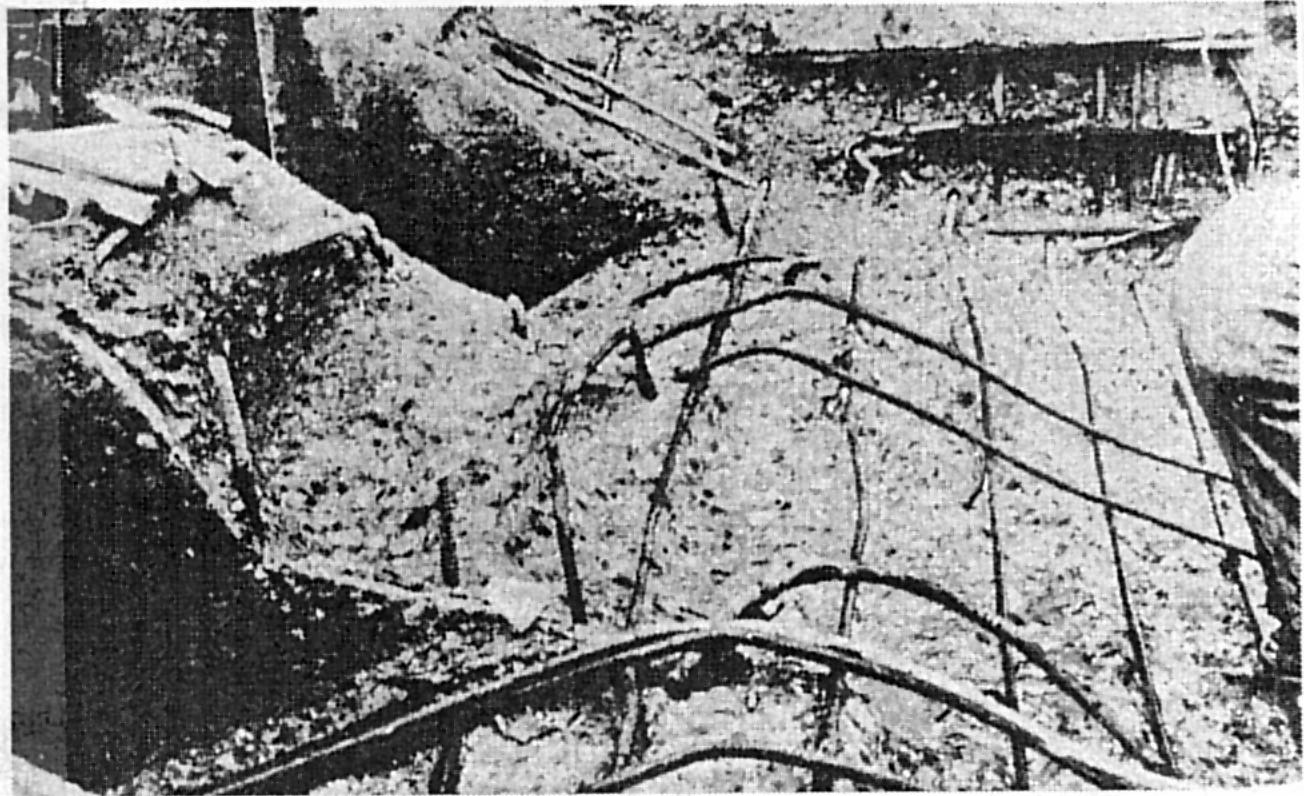

Cavitation erosion of intake lock at point of tunnel contraction wall of a navigation

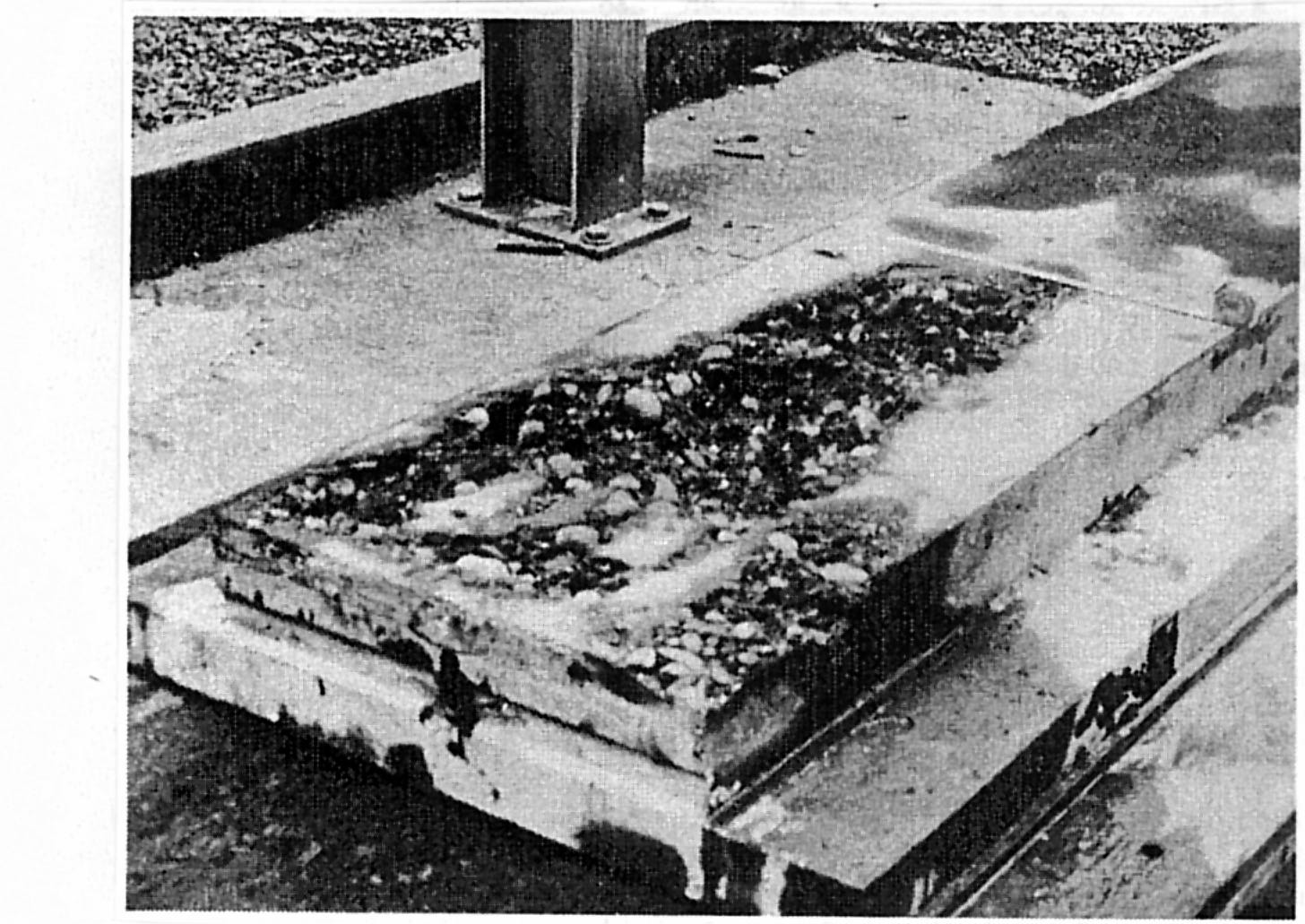

Concrete test slab fe aturing cavitation producing devices

Cavitation erosion pattern after 47 hours of testing at a 240 ft velocity head

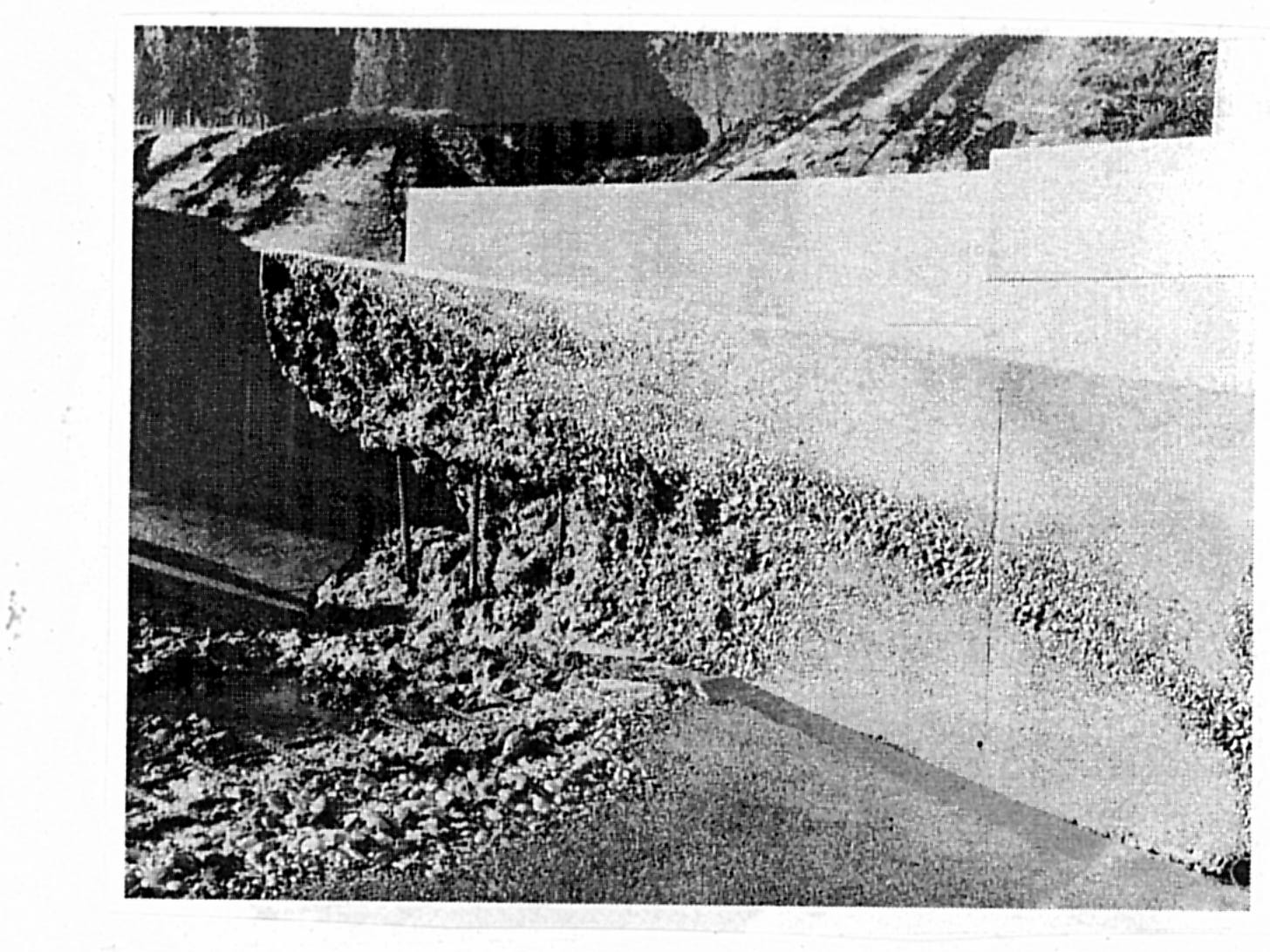

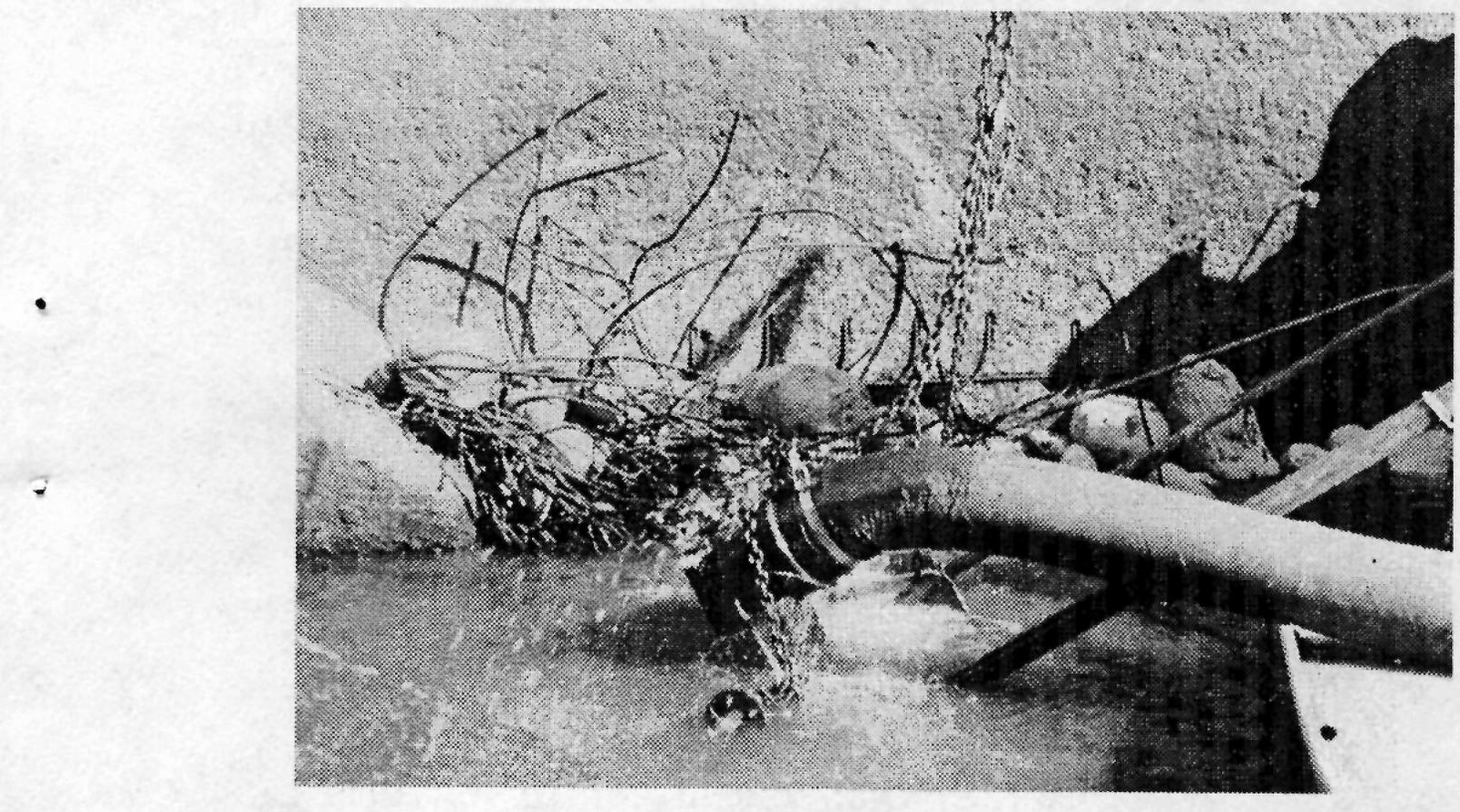

Cavitation erosion of discharge outlet training wall and flip bucket

Cavitation erosion of baffle block and floor in stilling basin

Abrasion damage to concrete baffle blocks and floor area

Abrasion erosion damage to stilling basin, Nolin Dam

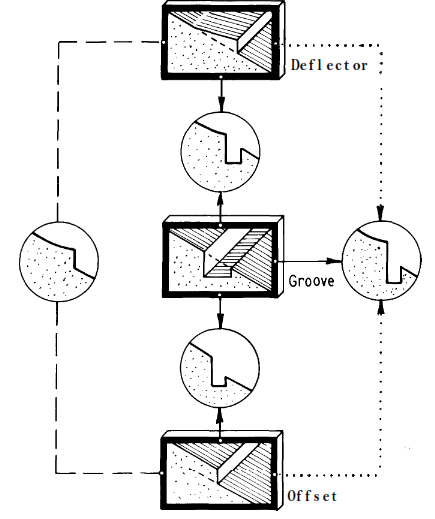

Types of aerators

Air supply to aerators

Recommended cement types to use in concrete when mixing water contains sulfates

Chapter 2-Erosion by cavitation

2.1-Mechanism of cavitation

2.2-Cavitation index

2.3-Cavitation damage

Chapter 3-Erosion by abrasion

3.1-General

3.2-Stilling basin injury

3.3-Navigation lock injury

3.4-Tunnel lining injury

Chapter 4-Eros particle by chemical attack,

4.1-Sources of chemical attack

4.2-Erosion by mineral-free water

4.3-Erosion by miscellaneous causes

PART 2-CONTROL of abrasion

Chapter 5-Control of cavitation erosion

5.1-Hydraulic style principles

5.2-Cavitation indexes for injury and construction tolerances

5.3 – Usi nanogram aeration to manage injury

5.4-Fatigue caused by vibration

5.5-Materials

5.6-Materials testing

5.7-Construction practices

Chapter 6-Control of abrasion erosion

6.1-Hydraulic concerns

6.2-Material analysis

6.3-Materials

Chapter 7-Control of abrasion by chemical attack

7.1-Control of abrasion by mineral-free water

7.2-Control of abrasion from microorganism action

7.3-Control of abrasion by miscellaneous chemical causes

PART3-MAINTENANCE AND REPAIR of abrasion

Chapter 8-Periodic inspections and corrective action

8.l-General

8.2-Inspection program

8.3-Inspection procedures

8.4-Reporting and analysis

Chapter 9-Repair ways and materials

9.1-Design concerns

9.2-Methods and materials

Chapter 1O-References

10.1-Specified and/or suggested references

10.2-Cited references