This article is about BASIC CALIBRATION FUNCTIONS IN FLUKE PROCESS HART CALIBRATOR and focusing to the engineers, technicians and supervisors. You will find lot of documents related to this article. Just navigate our website www.paktechpoint.com and find more articles. Please! Do not forget to subscribe our You tube channel also. Thanks in Advance.

PLEASE SUBSCRIBE OUR PAKTECHPOINT YOUTUBE CHANNEL

BASIC CALIBRATION FUNCTIONS IN FLUKE PROCESS HART CALIBRATOR HART means Highway addressable remote transducer. It is hybrid (analog plus digital) open protocol for instrumentation industry . This HART is alternative to 4-20 mA signal and superimposed on 4-20 mA signal with additional indformation. This is called HART commmunication protocol.

Read also more about HART::::: HART Communication Protocol & its Application

Following points to be covered in this article.

·Identify and communicate with HART transmitters over the bus

·Read transmitter process variable value (PV)

·Read and change range value (LRV, URV)

·Review and change basic sensor configuration.

·Calibrate most input sensor sections

·Perform output trim (4-20 mA) on all transmitters with universal command implementation.

Command Sets, three types.

•Universal commands –Provides functions that are implemented in all field devices

»Read manufacturer and device type; read primary variable (PV); read current output and percent of span.

•Common practice commands –Provides functions that are common to many but not all field devices

»Read multiple variables; calibrate (set zero, set span); perform self-test; read or write dynamic variable assignments.

•Device-specific commands –Provides functions that are unique to a particular field device

»Start, stop or clear totalizer; read or write density calibration factor; choose primary variable (mass flow or density)

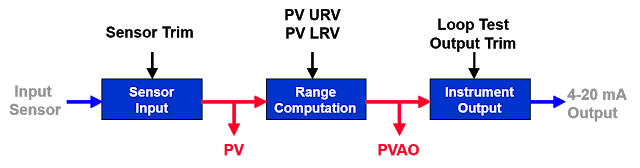

Smart transmitter •Three stages

–Sensor block

»Converts temperature signal to digital (A/D)

–Range computation

»Holds the programmed settings for zero (LRV) and span (URV)

»Outputs PVAO digital mA output signal

–Output section

»Receives the PVAO command and output the mA signal (D/A)

•Input and output section are individually calibrated to provide overall performance

744 HART Support

·Display, store and retrieve HART-specific data from an instrument.

·Automated HART calibration (trim) procedures for selected devices.

·Support for all Universal commands.

·Support for most Common-practice commands.

·RequiredDevice-specific commands for selected devices.

Calibrating with the 744 HART Process calibrator

1. Connect 744 HART requires only two additional connections.

2. Acquire transmitter characteristics

Simply press “HART” key

3. Execute “As-Found” test

Procedure template automatically filled out

4. Press “Adjust” Sensor

Trim and Output Trim performed automatically for supported devices

5. Execute automated “As-Left” test

Step 1 – Connect 744 •Connect mA measure/loop power the same as you would an Analog transmitter.

•Connector sensor input to calibrator source.

•Using HART cable connect serial port to instrument power input.

–polarity does not matter

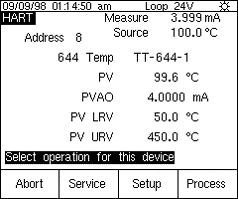

– Acquire the Transmitter

•Press “HART” key

–you may need to turn on Loop Power

–if in multi-drop configuration a particular device needs to be selected

•Press any key to clear warnings

•View device information

3 – Select the Measurement Parameter

•Select mode of operation

–MEAS mA for analog systems

–MEAS PV for digital systems

•Press “As-Found”

•Select “Instrument”

–Procedure template is almost complete

–fill in the tolerance, 0.25%

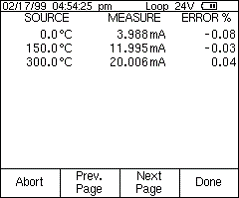

4a – As Found Test & Results

•Select the “Done” softkey

•Select “Autotest” to initiate the documented test

•From the post test summary, depress “Done” until the split screen reappears

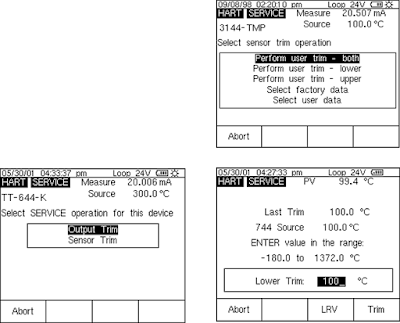

5- Adjust

•Press “Adjust”

–“Sensor Trim”

–“Perform User Trim – Both”

–Trim the LRV

–Continue to trim the URV

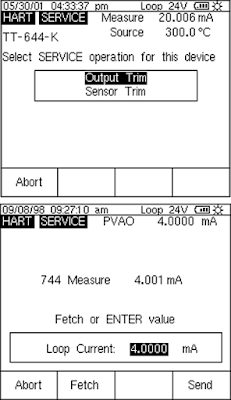

–“Output Trim”

–”Fetch” retrieves the current value being measured

–“Send” transmits to instrument and performs adjustment

–“Continue” and repeat the process for 20 mA

Like this: Like Loading...