For smooth operation and performance of Sliding Door, the proper installation guidelines should be followed:

WE RECOMMEND YOU EXAMINE THE MATERIALS PACKING LIST AND VERIFY HANDING OF DOORS,

OPENING SIZE AND QUANTITIES. BEFORE BEGINNING THE INSTALLATION, STUDY THE ERECTION

DETAILS AND THESE INSTRUCTIONS SO AS TO HAVE A CLEAR UNDERSTANDING OF ALL FACETS OF

INSTALLATION. WHEN PROPERLY INSTALLED AND MAINTAINED, YOURE AL KUHAIMI SLIDING DOORS WILL PROVIDE YEARS OF SATISFACTORY SERVICE.

Bottom Rolling Blast Resistance Sliding Doors Installation O&M Procedure

1. MOUNTING OF WALL BRACKET & TOP TRACK:

Determine the high point of the floor on the door side thru the entire opening width and the stacking space (opening width+ 600mm @ rear space & 200mm@ front space for single slide and½ opening width+ 600mm for Bi-Parting on both sides). Mark the centerline of the wall opening as this is the starting point of locating the wall bracket.

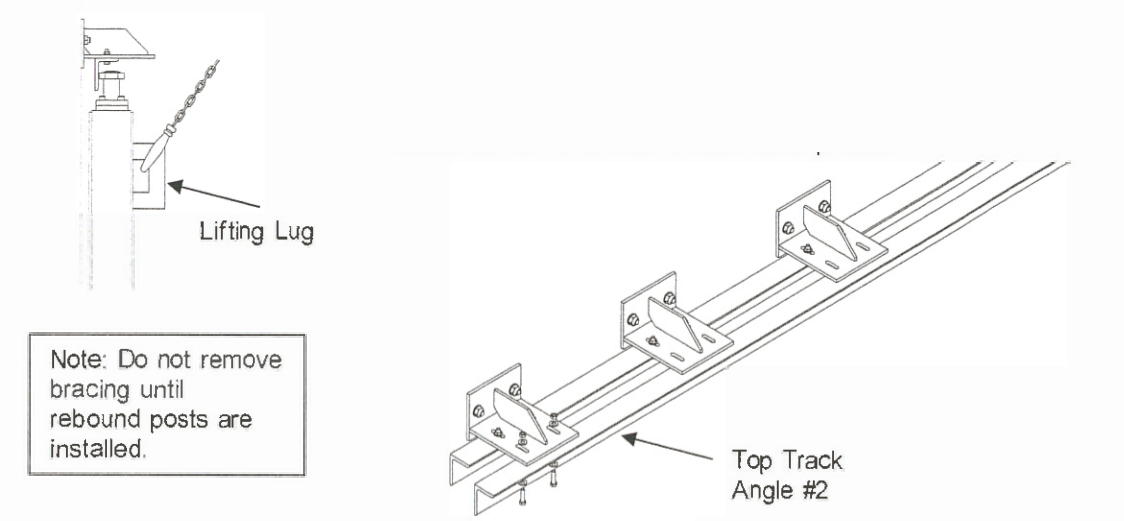

Assemble one top track angle to wall bracket, distance of wall bracket are already pre-drilled on the top track (Fig. 1) Once it is assembled mark the centerline of the top track.

Measure up the wall opening height plus 316mm (Fig. 2) (refer to approved shop drawing) as this is the centerline of the bolt and mark.

Locate the top track by aligning the centerline of top track to the centerline of opening. Using the top track as a template, mark the locations of the holes and drill the holes for M 16 stud Anchor. Make sure that the track is level. If the continuous track is installed out of level, it will not allow the door to slide freely. After the holes are drilled, install the_track with M16 Stud Anchor. See Below figure

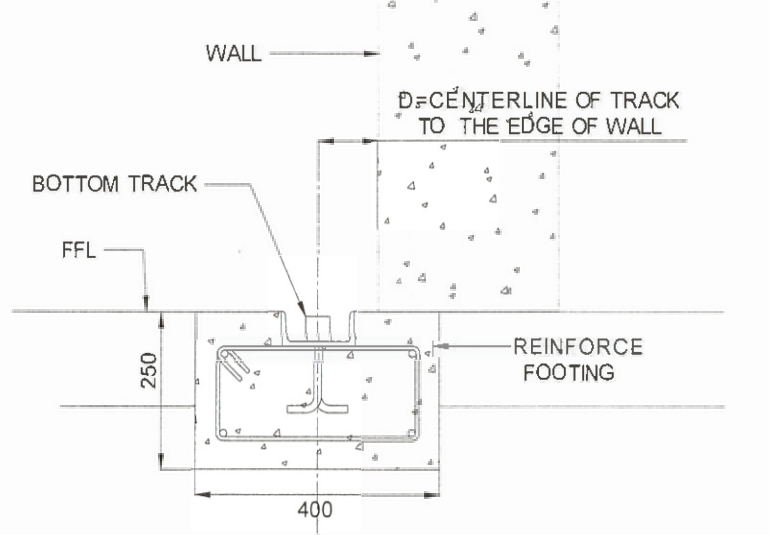

2. MOUNTING OF BOTTOM TRACK:

Install Bottom track assembly as indicated on the shop drawings. Bottom track must be installed true and level to permit smooth and easy to slide.

Check the alignment (centerline of the top track shall be aligned to the centerline of the bottom track and levelness of the bottom track prior to concrete casting. Dimension D, please refer to shop drawing

3. ASSEMBLY OF DOOR:

Note: For Bi-Parting sliding door, step 4 can be first prior to installation of door. Lift up the door panel using lifting lug. Ensure that the clearances shown on the drawing are followed.

Note:

1. Use appropriate Heavy lifting equipment (e.g. crane, forklift)

2. Lifting shall be removed after installation of the assembly.)

3. Ensure safety precaution during erection of door panel.

3. After the door panels are placed and properly braced . You can now start to fix the other side of top track.

4. INSTALL THE REBOUND POST.

Place the rebound post as shown on the drawing, mark and drill the holes for M16 stud anchor.

5. INSTALL THE DOOR STOP.

Remove all bracing and lifting lug and slide the door completely open and locate the door stopper as shown on the

shop drawings. Mark and drill hole for stud anchor. Install the door stop with M10 stud anchor.

6. OPERATION OF DOOR.

Check to make the certain door now rolls and slides freely. If the wall is rough or uneven, it may be necessary to

face it off to eliminate unnecessary rubbing of the door. In most cases minor track alignment can be made by the

adjustment slot in the wall mounted angle bracket.

7. FOR MOTOR OPERATOR.

Position the motor base as shown on the approved shop drawings taking into consideration the required

clearances mention in the motor installation instruction manual (if any). Fix the motor on to the concrete floor.

8. WIRE IN MOTOR OPERATOR: SEE ELECTRICAL SCHEMATIC

To maintain the integrity of the system, all electrical work must be performed by qualified technicians.

Once all of the above has been taken care of, you will be able to easily slide your door manually, when the door

moves easily manually, than you can hook up the operator to the door electrically. Follow the instruction stipulated

in the motor installation instruction manual or booklet found with the shipment of motor operator.

THE DOOR MUST MOVE FREEELY MANUALLY TO INSURE THE OPERATOR WILL GIVE YOU TROUBLE FREE SERVICE.

9. DOOR MAINTENANCE:

Very little maintenance is required to keep sliding door in fine operating condition. Ordinary maintenance is limited to periodic inspection to be certain all parts are functioning properly and freely. Attention should be given to be certain no obstructions are placed in the way of travel path of the door. Any damage to the door or door parts by inter-plant accidents should be repaired immediately to assure proper operation of the door.