Main keywords for this article are Cable Tray Installation Details With Pictures, Cable Tray Installation Details DWG, Cable Tray Installation Drawings, Cable Tray Support Span Calculation, Cable Tray Support Brackets.

CABLE TRAY INSTALLATION DETAILS WITH PICTURES

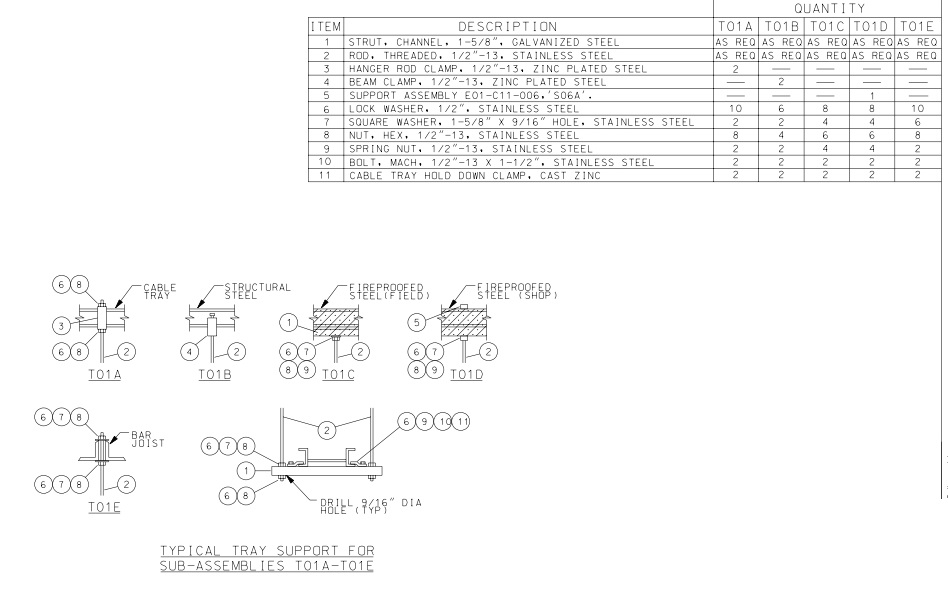

CABLE TRAY TRAPEZE SUPPORT ASSEMBLY STRUT

CABLE TRAY CLAMP ASSEMBLY

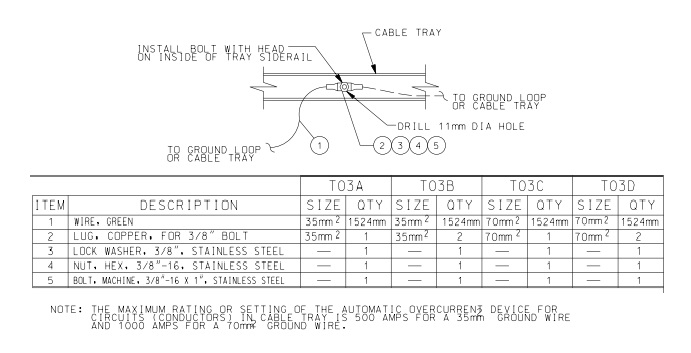

CABLE TRAY GROUNDING ASSEMBLY

ALUMINUM CABLE TRAY HINGED – SPLICE PLATE ASSEMBLY

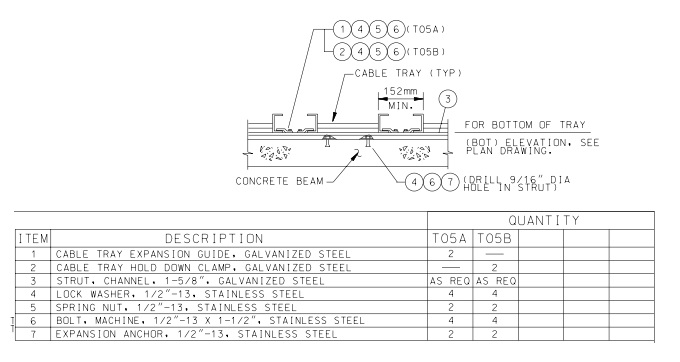

CABLE TRAY CLAMP ASSEMBLY – ASSEMBLY CONCRETE BEAM

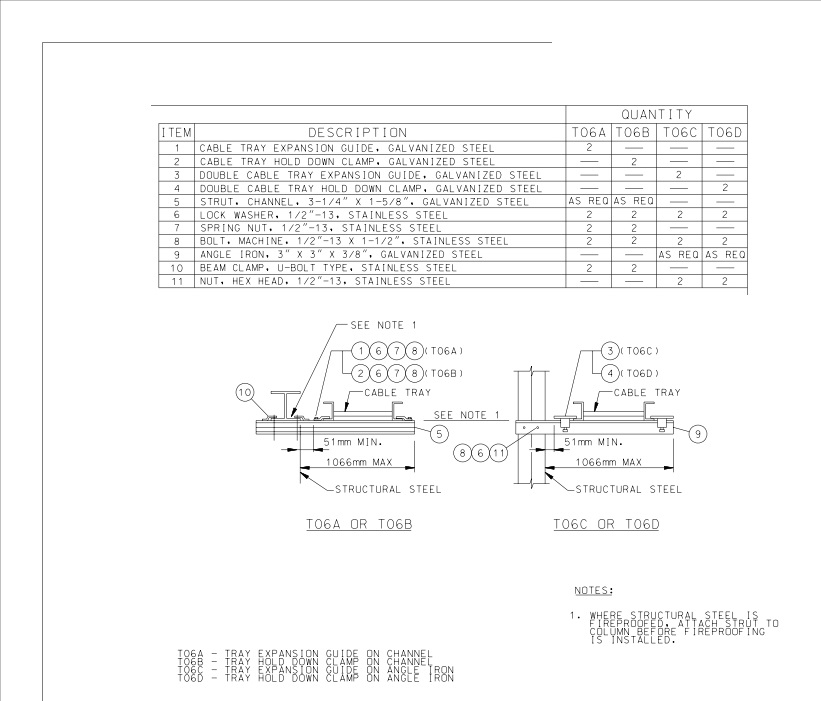

CABLE TRAY SUPPORT FROM VERTICAL – STRUCTURAL STEEL ASSEMBLY

NOTES:

1. WHERE STRUCTURAL STEEL IS FIREPROOFED, ATTACH STRUT TO COLUMN BEFORE FIREPROOFING IS INSTALLED.

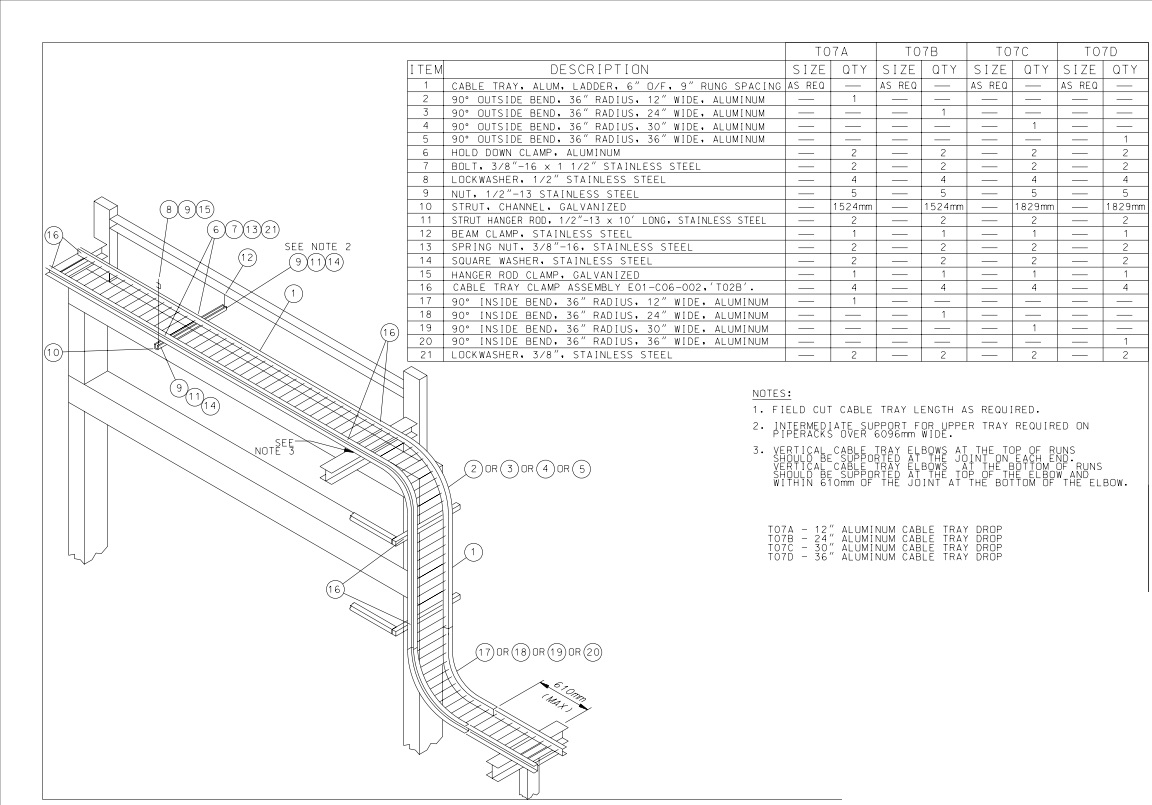

TRAY DROP ASSEMBLY SPAN DROP – TOP OR FRONT ONLY

NOTES:

1. FIELD CUT CABLE TRAY LENGTH AS REQUIRED.

2. INTERMEDIATE SUPPORT FOR UPPER TRAY REQUIRED ON PIPERACKS OVER 6096mm WIDE.

3. VERTICAL CABLE TRAY ELBOWS AT THE TOP OF RUNS SHOULD BE SUPPORTED AT THE JOINT ON EACH END. VERTICAL CABLE TRAY ELBOWS AT THE BOTTOM OF RUNS SHOULD BE SUPPORTED AT THE TOP OF THE ELBOW AND WITHIN 610mm OF THE JOINT AT THE BOTTOM OF THE ELBOW.

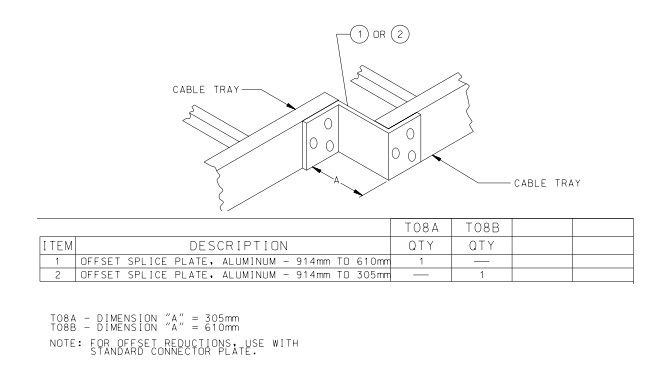

ALUMINUM OFFSET SPLICE PLATE – ASSEMBLY

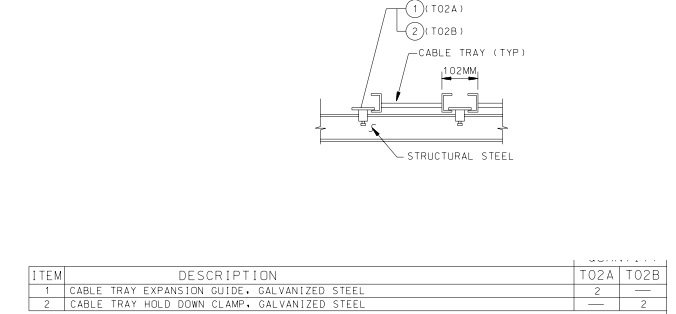

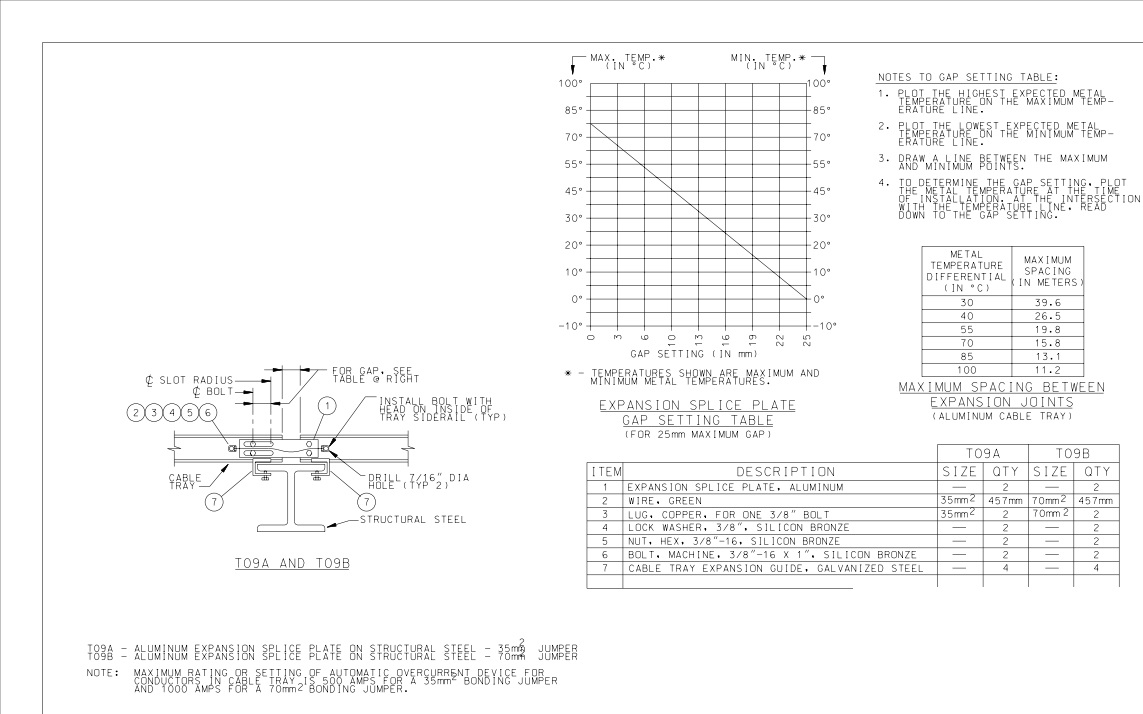

ALUMINUM EXPANSION SPLICE PLATE – ASSEMBLY

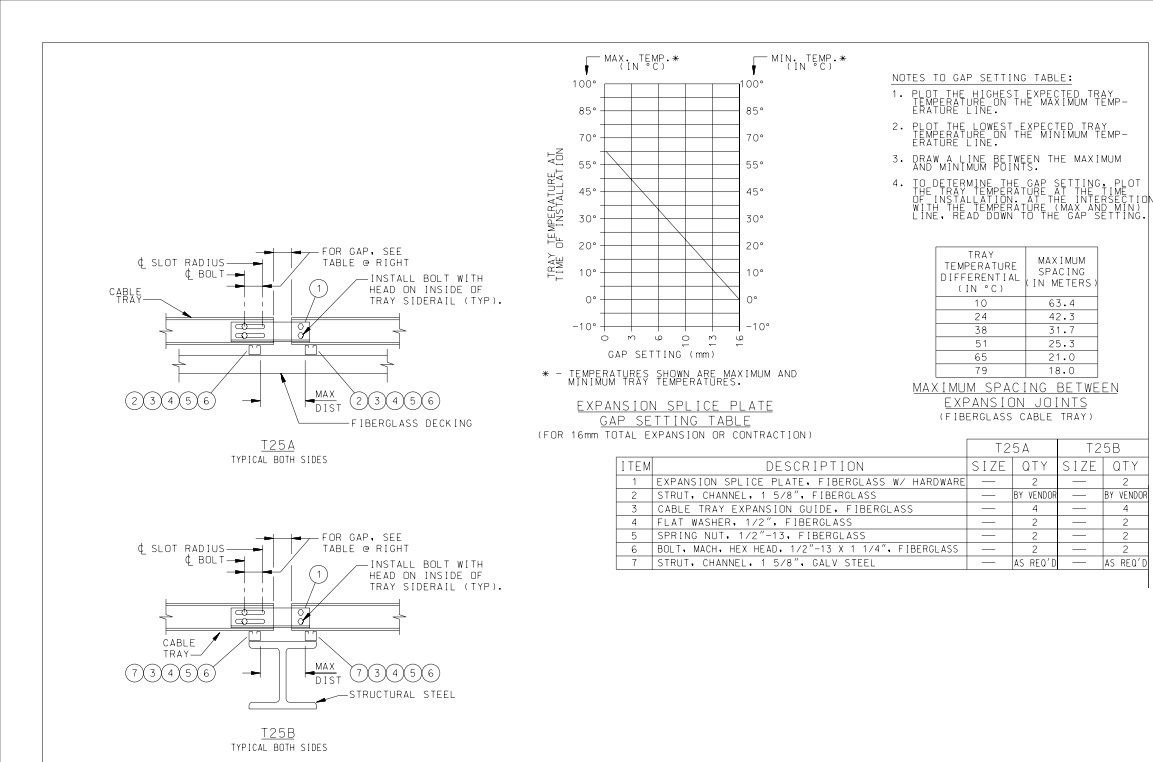

NOTES TO GAP SETTING TABLE:

1. PLOT THE HIGHEST EXPECTED METAL TEMPERATURE ON THE MAXIMUM TEMPERATURE LINE.

2. PLOT THE LOWEST EXPECTED METAL TEMPERATURE ON THE MINIMUM TEMPERATURE LINE.

3. DRAW A LINE BETWEEN THE MAXIMUM AND MINIMUM POINTS.

4. TO DETERMINE THE GAP SETTING, PLOT THE METAL TEMPERATURE AT THE TIME OF INSTALLATION. AT THE INTERSECTION WITH THE TEMPERATURE LINE, READ DOWN TO THE GAP SETTING.

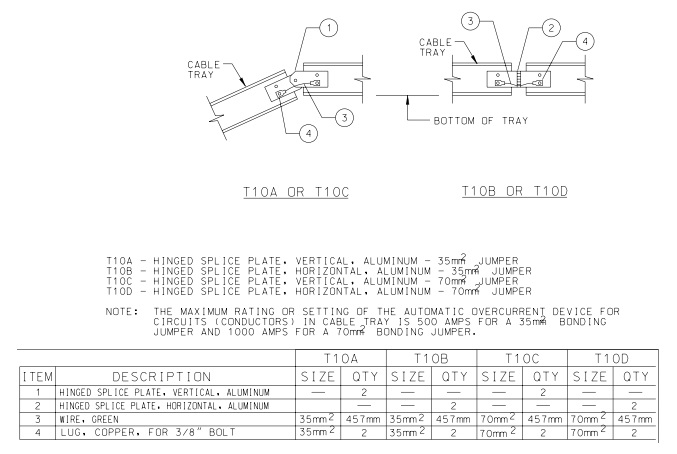

ALUMINUM CABLE TRAY HINGED – SPLICE PLATE ASSEMBLY

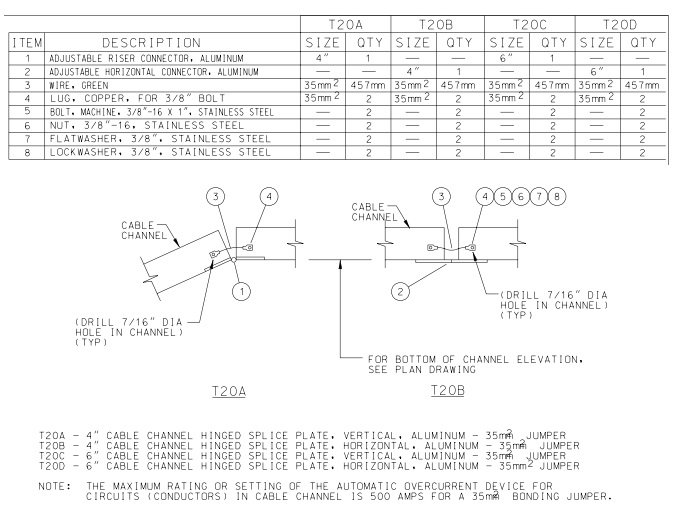

NOTE: THE MAXIMUM RATING OR SETTING OF THE AUTOMATIC OVERCURRENT DEVICE FOR CIRCUITS (CONDUCTORS) IN CABLE TRAY IS 500 AMPS FOR A 35mm BONDING PER AND 1000 AMPS FOR A 70mm2 BONDING JUMPER.

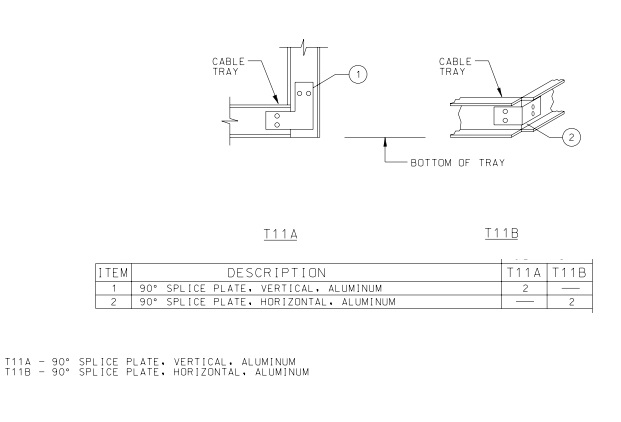

ALUMINUM CABLE TRAY 90 DEGREES – SPLICE PLATE ASSEMBLY

CABLE TRAY FIRE SHIELD – ASSEMBLY

NOTE: SLOPE FOR WATER TO DRAIN, SHALL BE ACHIEVED BY ADDING MORE WASHERS (ITEM 4) BETWEEN SPACER COUPLINGS (OR TUBINGS) AND FIRE PROTECTION SHEET, IN ONE SIDE OF THE TRAY THROUGHOUT THE LENGTH.

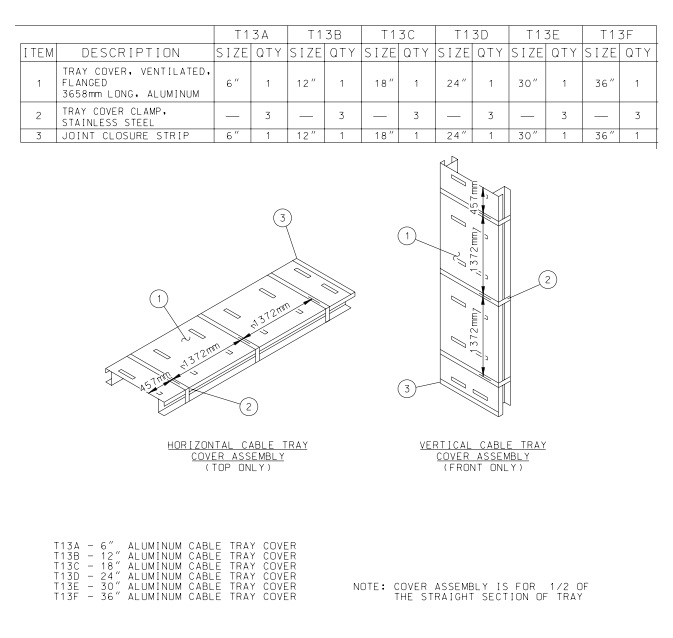

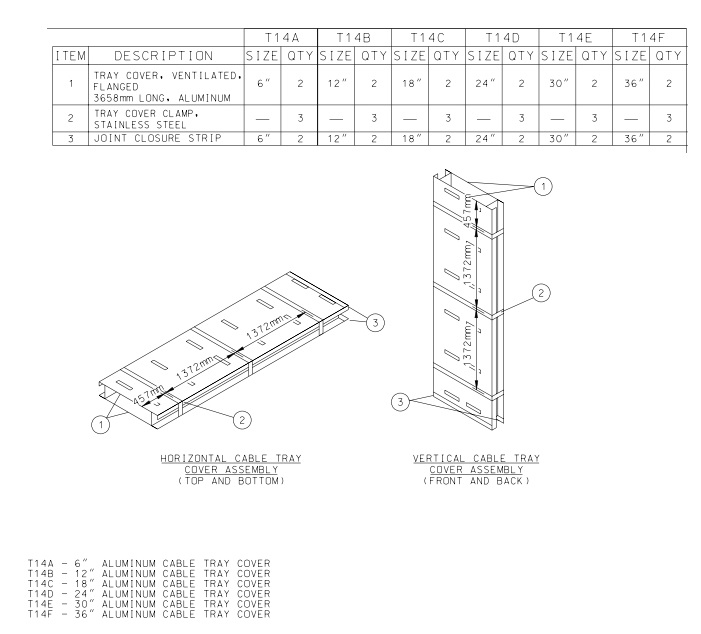

ALUMINUM CABLE TRAY COVER – ASSEMBLY

ALUMINUM CABLE TRAY COVER – BOTH SIDES

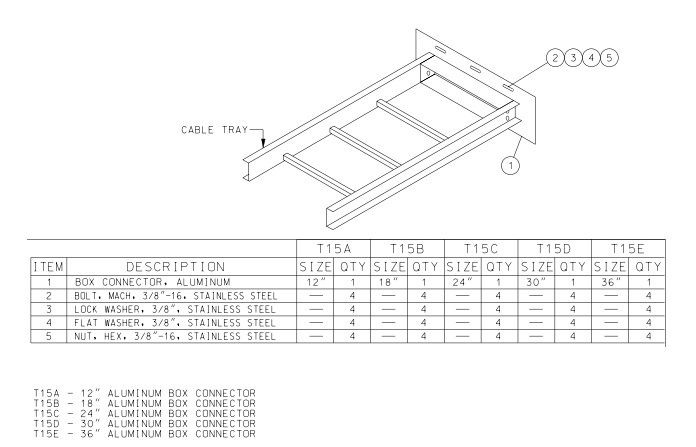

ALUMINUM BOX CONNECTOR – ASSEMBLY

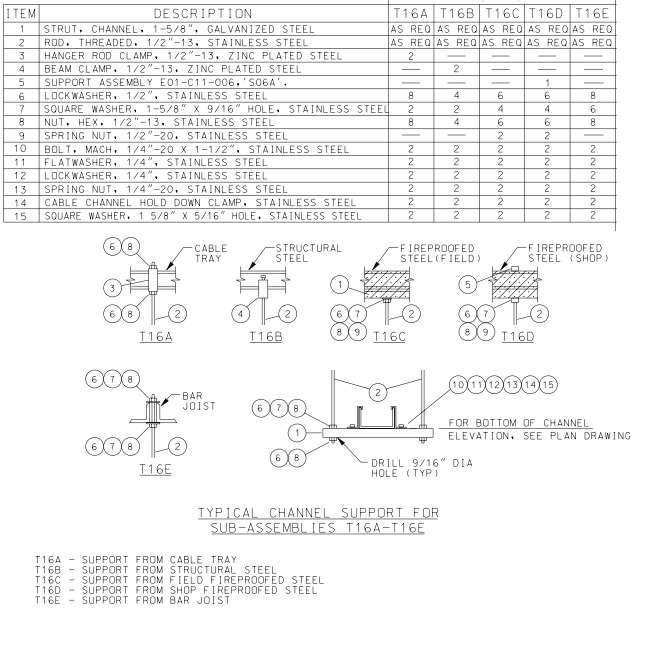

CABLE CHANNEL TRAPEZE SUPPORT – ASSEMBLY STRUT

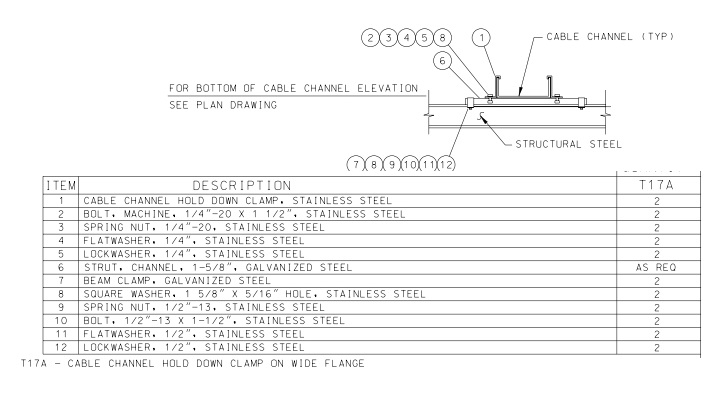

CABLE CHANNEL CLAMP ASSEMBLY – (ON WIDE FLANGE)

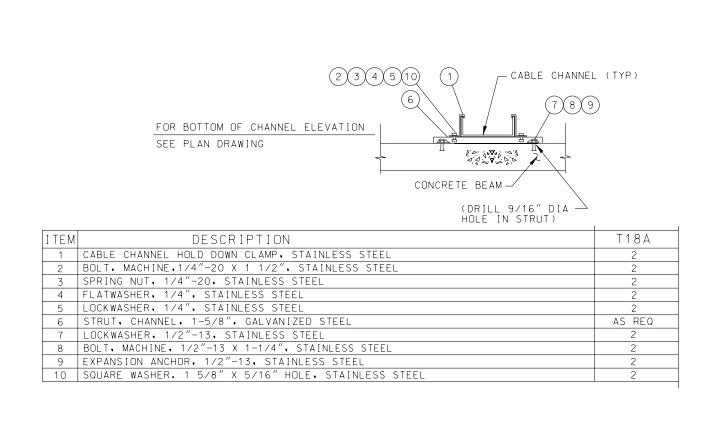

CABLE CHANNEL CLAMP ASSEMBLY – (ON CONCRETE BEAM)

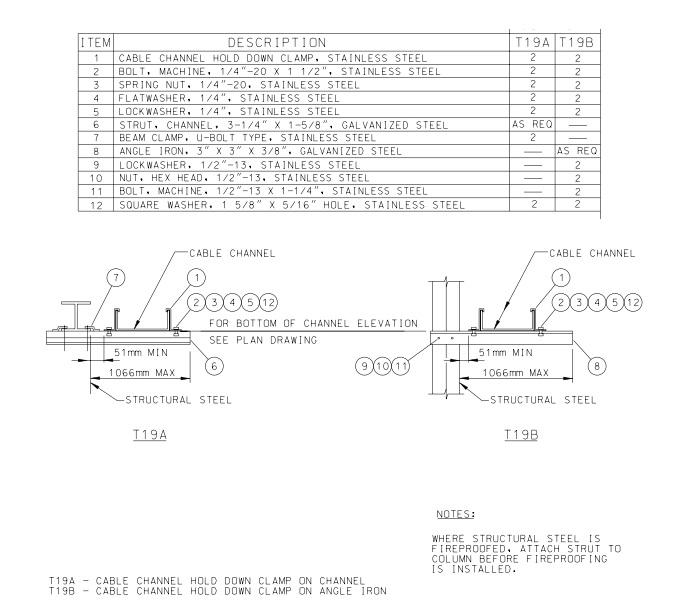

CABLE CHANNEL SUPPORT FROM VERTICAL – STRUCTURAL STEEL ASSEMBLY

NOTES:

WHERE STRUCTURAL STEEL IS FIREPROOFED, ATTACH STRUT TO COLUMN BEFORE FIREPROOFING IS INSTALLED.

ALUMINUM CABLE CHANNEL HINGED – SPLICE PLATE ASSEMBLY

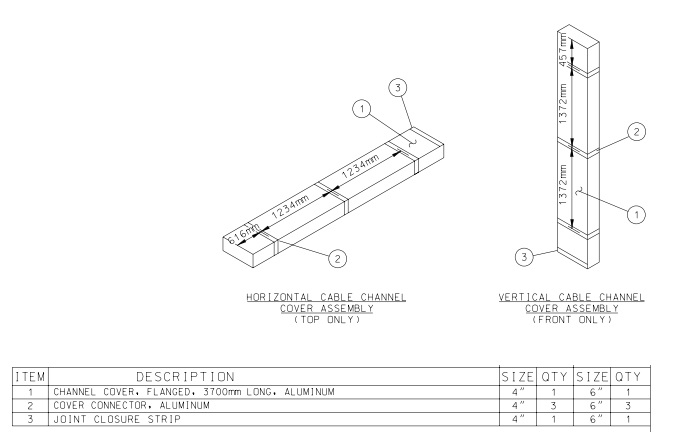

ALUMINUM CABLE CHANNEL COVER – ASSEMBLY

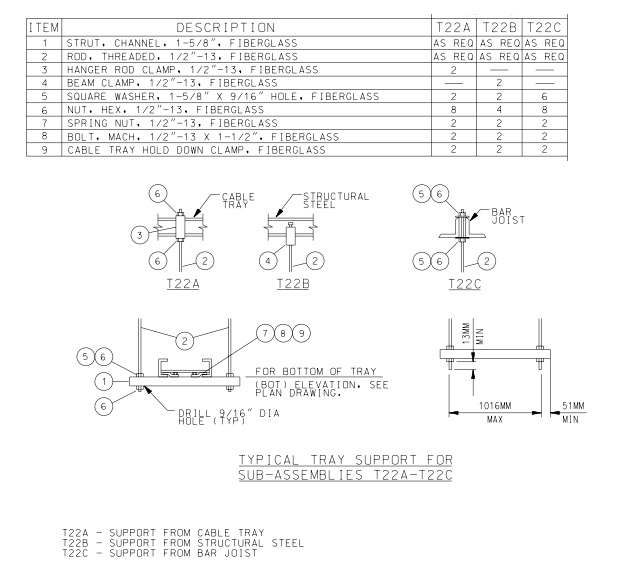

FIBERGLASS CABLE TRAY TRAPEZE SUPPORT – ASSEMBLY STRUT

FIBERGLASS CABLE TRAY CLAMP – ASSEMBLY

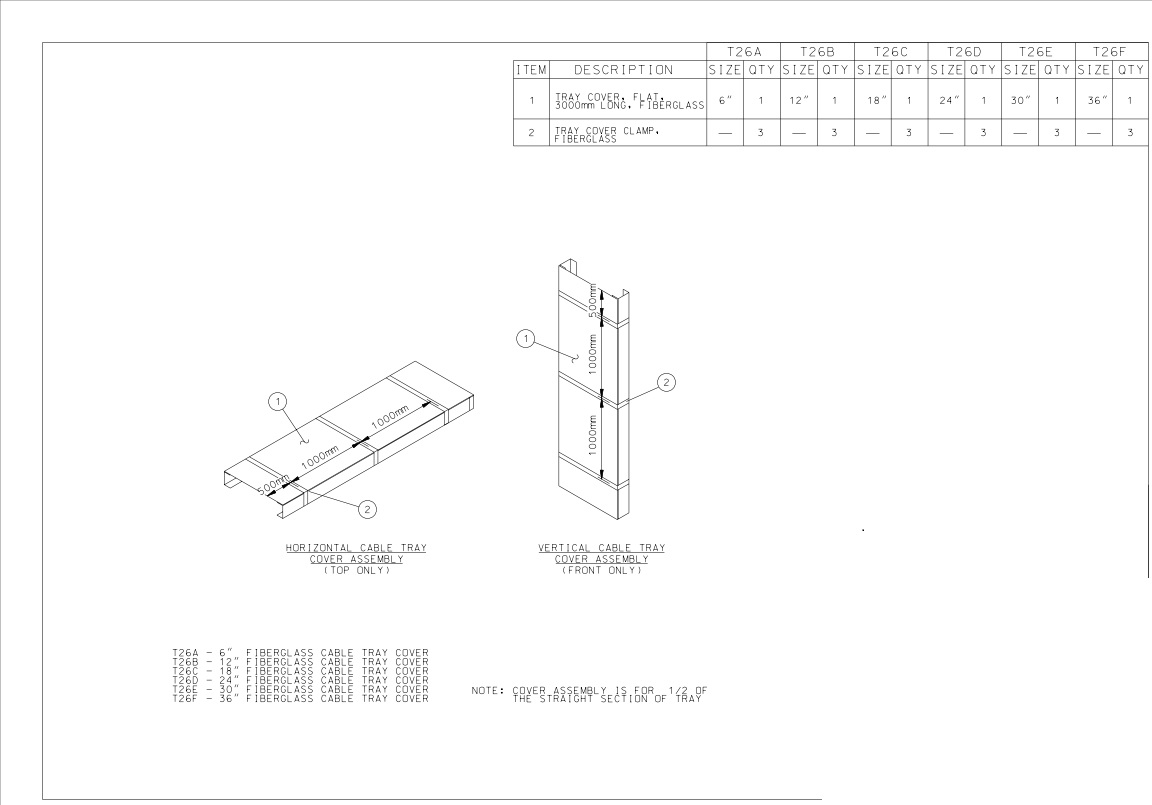

FIBERGLASS CABLE TRAY – COVER ASSEMBLY

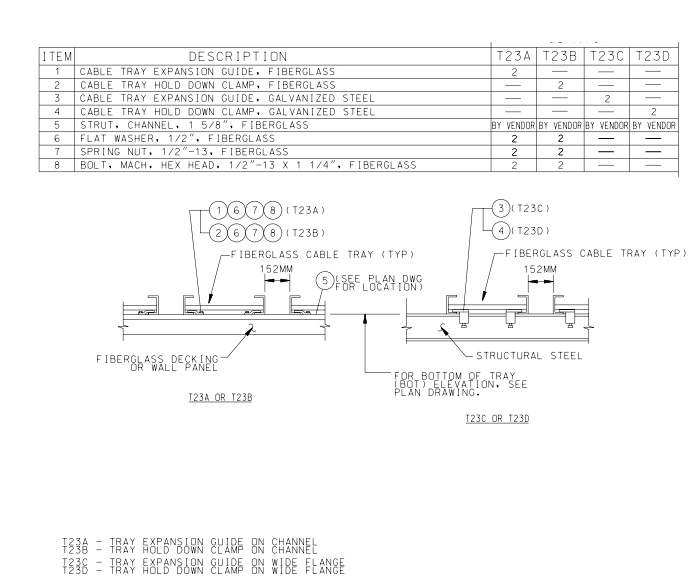

FIBERGLASS EXPANSION SPLICE PLATE ON CHANNEL – ASSEMBLY

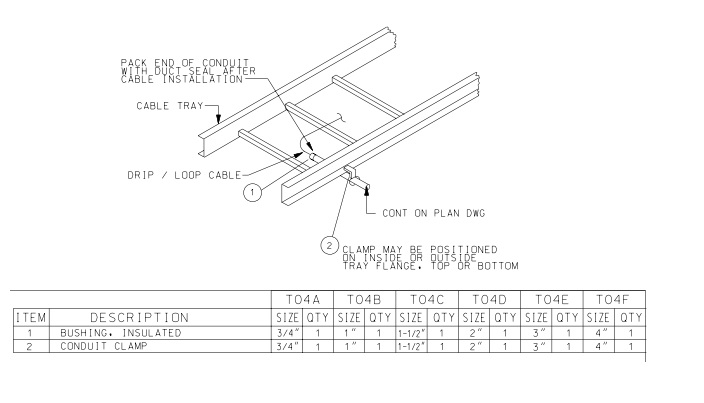

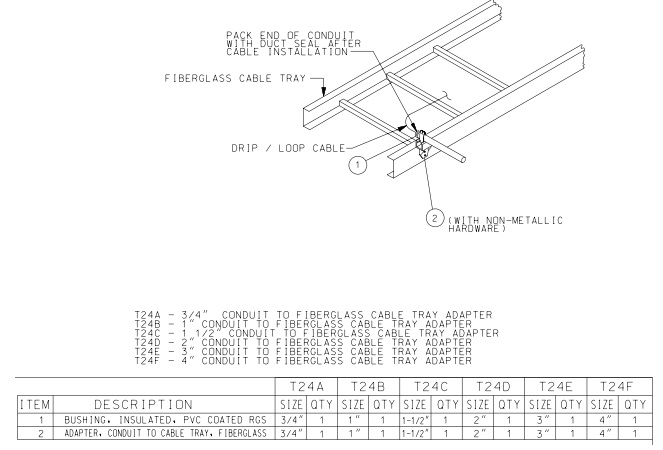

WIRE OR CABLE IN FIBERGLASS TRAY – TO CONDUIT ASSEMBLY

We have discussed Main keywords for this article are Cable Tray Installation Details With Pictures, Cable Tray Installation Details DWG, Cable Tray Installation Drawings, Cable Tray Support Span Calculation, Cable Tray Support Brackets.

- GROUNDING INSTALLATION DETAILS

- LIGHTING INSTALLATION DETAILS

- Electrical Motor Installation Details

- Receptacle Electrical Installation Details

-

PANEL BOARDS INSTALLATION DETAILS

-

Cable Tray – Wikipedia Reference