This article is about COMPLETE OVERVIEW OF PROGRAMMABLE LOGIC CONTROLLER PLC and focusing to the engineers, technicians and supervisors. You will find lot of documents related to this article. Just navigate our website www.paktechpoint.com and find more articles. Please! Do not forget to subscribe our You tube channel also. Thanks in Advance.

OVERVIEW OF PROGRAMMABLE LOGIC CONTROLLER PLC

A digital Electronic Device Uses a programmable memory to store instructions & to implement functions as

- Logic

- Sequencing

- Timing

- Counting

- Arithmetic

- In order to control machines & Process

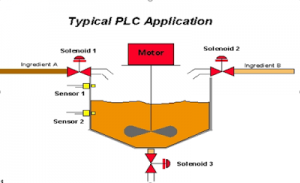

- INPUT devices as switches & o/p devices as motors are connected to PLC.

- Controller monitors the inputs & o/ps according to the program stored in the PLC.

Uses Programmable Logic Controller

- Cost effective for controlling complex systems.

- Ladder logic programming can be applicable for other control system.

- Computational abilities allow more sophisticated control.

- Trouble shooting aids make programming easier and reduce downtime.

- Programming is easier and troubleshooting reduce downtime.

- Reliable components make these likely to operate for years before failure.

- Easy to modify a control system without rewiring the connections to input & o/p devices. Much faster than relay-operated systems

- Widely used for the implementation of logic control functions.

- Easy to use

- Reliability of PLC is greater

- Maintenance is easier

- PLCs take less floor space than do relay control panels.

- Can perform a greater variety of control functions than relay control

- Virtual real-time control becomes feasible

- Used for implementing automatic control of manufacturing systems

- Logical information is rapidly and repeatedly processed and immediately responded to with appropriate actions

- A series of logical decisions have to be made and a variety of actions taken on the basis of input that is obtained from appropriate sensors.

Features of PLC

- PLCs are designed to withstand with vibration, humidity, noise, temperature and any environmental changes.

- The main feature is interfacing for input and output is inside the controller.

- They are easily programmed.

Programmable Logic Control (PLC)

Definition – Dedicated computer for rapid processing of simple logic instructions in a defined time.

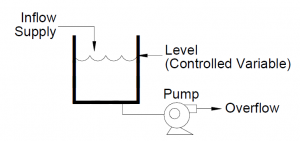

Purpose – Send and read signals that can be used to control and monitor devices.

Process – One of scanning all the devices (sensors, timers, etc.) in a cyclical time period.

PLC Control Approaches

Logic Control Method – This closed-loop method uses conditions and events to signal completion of a given step, and then triggers the execution of some other event. This is an asynchronous method of process control, because it does not always proceed in a constant time period.

Sequencing Method – This open-loop method uses timers to trigger the completion of one step and the beginning of the next. This is a synchronous control method.