Temperature has a substantial effect on insulation resistance readings, and correcting these readings to a standardized temperature is a common practice to ensure accurate and meaningful results during insulation testing. Maintaining consistency in testing conditions is vital for effective monitoring of insulation condition over time.

Effect of Temperature on Insulation Resistance

1. Temperature’s Impact on Resistance:

- The resistance of insulating materials significantly decreases with rising temperatures. However, tests using the time-resistance and step-voltage methods are relatively unaffected by temperature variations, providing relative values.

2. Ensuring Reliable Comparisons:

- To make reliable comparisons between readings, it’s essential to either correct the readings to a base temperature, such as 20°C, or ensure that all readings are taken at approximately the same temperature.

3. Temperature Correction Rule:

- A general rule of thumb is that for every 10°C increase in temperature, the resistance is halved, while for every 10°C decrease, the resistance is doubled. For instance, a 2-megohm resistance at 20°C would reduce to 1/2 megohm at 40°C.

4. Factors for Temperature Correction:

- Correction factors have been developed to simplify the process of adjusting resistance values for temperature variations. Table II provides these correction factors for rotating equipment, transformers, and cables. To correct readings, multiply them by the factor corresponding to the measured temperature.

5. Example of Temperature Correction:

- Suppose you have a motor with Class A insulation, and you measure a resistance of 2.0 megohms at a winding temperature of 104°F (40°C). Referencing Table II for Class A at 104°F, you find the correction factor to be 4.80. Therefore, your corrected resistance value would be: Corrected Resistance = 2.0 megohms × 4.80 = 9.60 megohms

6. Consistency in Temperature Correction:

- It’s important to be consistent in correcting readings to the same base temperature. While the reference temperature for cable is 60°F (15.6°C), the key is to ensure uniformity in corrections.

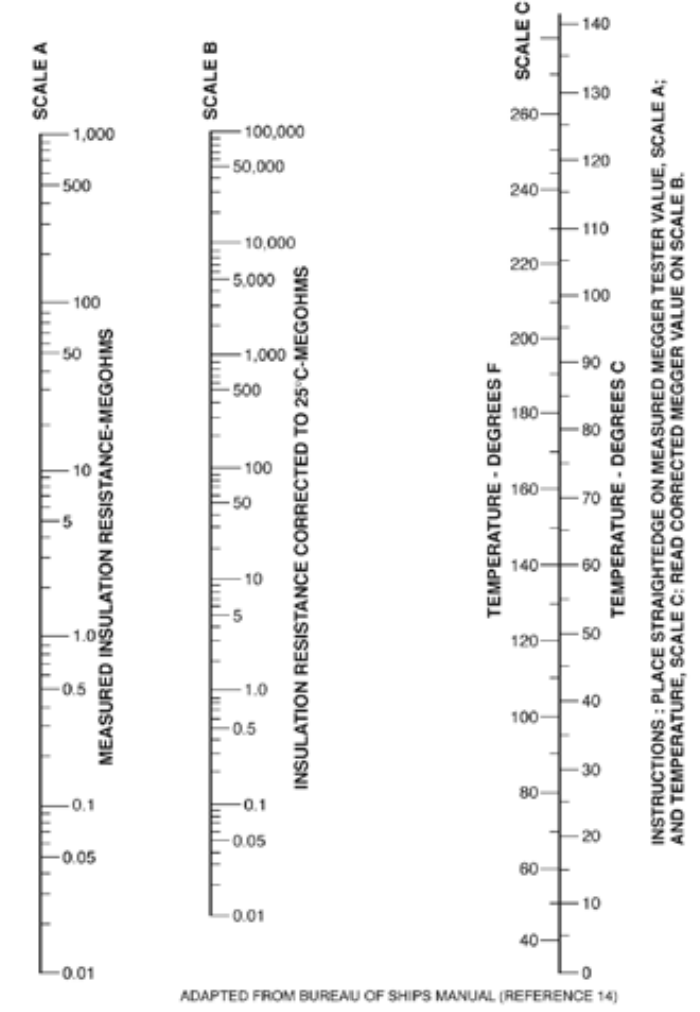

7. Nomograph for Temperature Correction:

- A nomograph can be used to determine temperature correction values for Megger readings, correcting them to a standard temperature of 25°C. This helps ensure uniformity and accurate comparisons.

In summary, temperature can significantly impact insulation resistance readings. Correcting these readings to a standard base temperature or maintaining consistent testing conditions is crucial for reliable comparisons and accurate assessment of insulation condition.

Related Articles:

What is Good insulation?

What Makes Insulation Go Bad?

How Insulation Resistance is Measured.

How to Interpret Resistance Readings.

Factors Affecting Insulation Resistance Readings.

Types of Insulation Resistance Tests.

Test Voltage vs. Equipment Rating.

AC Testing vs. DC.

Use of DC Dielectric Test Set.

Tests During Drying out of Equipment.

Effects of humidity.

Preparation of Apparatus to test.

Safety Precautions.

Connections for testing insulation resistance of electrical equipment.

Additional Notes About using A Megger Insulation Tester.

Interpretation-Minimum Values.

Minimum Values for Insulation Resistance.

Tests Using Multi-Voltage Megger Insulation Testers.

Step-Voltage Method.

Use of a Guard Terminal.

Outdoor Oil Circuit Breaker.