Electric Motor System Diagnostics Procedure

• The reliability and energy consumption of electric motors and the systems they drive has a direct financial impact to industrial and commercial enterprises.

• We will discuss the financial justification for a motor testing program, a general discussion of De-energized and Energized testing methods, and ideas for selling the service.

• Electrical Motor System testing is becoming an important part of a successful rotating equipment reliability testing program

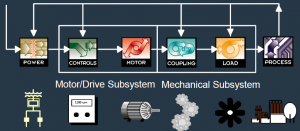

What is a Motor System?

The Electric Motor System

Three-Phase

Input Power Process Mechanical and Electrical Feedback

Motor System Faults

some common faults found within a motor system

Incoming Power

• Power Quality

o Harmonics (Voltage and Current)

o Over/Under Voltage

o Voltage Unbalance

o Power Factor

o Overload

Transformers

• Transformer Faults

o Insulation to Ground

o Winding Shorts

o Loose Connections

o Electrical Vibration

MCC – Controls and Disconnects

• MCC/Disconnect Problems

o Loose Connections

o Faulty Contacts

o Faulty Coils

o Faulty VFD

o Faulty Starter

o Bad PF Correction Capacitors

Cables (Before and After Controls)

• Cable Faults

o Thermal Breakdown

o Contamination (especially underground feeders)

o Shorts and Grounds

o Open

o Physical Damage

Electric Motor (Mechanical)

• Mechanical Faults

o Bearings

o Bad Shaft/Brg Housing

o Vibration

Electric Motor (Electrical)

• Electrical Faults

o Winding Shorts

o Insulation to Ground

o Contamination/Thermal Stress

o Rotor Faults

o Air Gap Faults

Coupling (Direct and Belted)

• Faults

o Misalignment

o Unbalance

o Belt/Insert Wear

o Tension Issues

o Sheave Wear

Load (Fans, Pumps, Compressors, Gearboxes, Etc.)

• Load Faults

o Worn parts (I.e. seals)

o Broken components (gears, fan, impeller blades, etc.)

o Bearings, etc

Where Electrical Faults Can Begin

• End turns of windings

o Stresses are greatest

o Insulation is weakest

o Most exposed to contamination

About Motor Electrical Faults

• They start small and get worse

• They always end in failure

• Contributing factors

o Overloading

o Frequent start/stop cycling

o Vibration

o Contamination

o Age, Heat, VF Drives

Other Types Of Electrical Faults

• Open Phases

• Broken/Cracked Rotor Bars

• Air gap (eccentricity)

• Blown Capacitors

• Poor Connections

• Cable Faults

• Overload, Fuses, etc.

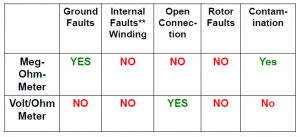

Meg-Ohm-Meter & Volt/Ohm Meter

When Used for Elec Motor Testing*

* Common electrical testing instruments **Coil faults- turn to turn & coil to coil

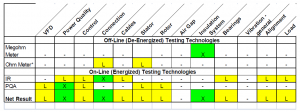

Combined Technology Approach

Typical Electrical Contractor Today

Green indicates that a developing fault can be both detected and trended for Predictive Maintenance purposes.

Yellow indicates a fault can be detected, but is difficult to trend or cannot be detected at an early stage.

* When using a typical DMM to measure resistance.

Combined Technology Approach

Contractor with MCA and ESA

Green indicates that a developing fault can be both detected and trended for Predictive Maintenance purposes.

Yellow indicates a fault can be detected, but is difficult to trend or cannot be detected at an early stage.

Why Add Motor Testing?

• Generates additional billable hours for your business

• Improves your customers’ equipment reliability

• Provides a more accurate assessment of your customers’ equipment when compared to what you are doing now

Why Offer An Electrical Motor Testing Program?

• Many of your customers have motor system reliability issues

• Some will not have the resources to support an in-house motor testing program

• Some of your customers will gladly pay for this service

• Motor testing equals extra billing $$

• Multi-Technology Approach to Motor Diagnostics

o Electrical motor testing will also improve your ability to detect and eliminate causes of system

failure

• Use De-Energized MCA and Energized ESA testing to validate findings from Infrared & Power Analysis test methods

Why Your Company for Electrical Motor Diagnostics?

• Improve Rotating Equipment Reliability

• Lower Your Operating Costs

• Lower Energy Consumption

• Improve Product Quality

• Increase Company Profits

• Improve Employee Safety

• Reduce Reactive Repair Time When Equipment Does Fail

I got what you mean , regards for posting.Woh I am happy to find this website through google.