This article is about Electrical Metallic Tubing EMT Material Selection Guide & Technical Specification for commercial buildings, plants and refinery projects as per international codes and standards. EMT shall be listed as meeting the requirements of ANSI C80.3. More details about

Electrical Metallic Tubing EMT Material Technical & Technical Specification

| Circular cross section: Electrical metallic tubing shall have a circular cross section sufficiently accurate to permit the application of identified EMT fittings. [ANSI C80.3 Sec. 5.1] |

| Wall thickness: The wall thickness shall be uniform throughout. [ANSI C80.3 Sec. 5.2] |

| Interior surface: The interior surface shall be free from injurious defects. [ANSI C80.3 Sec. 5.3] |

| Welding: The welding of all seams shall be continuous and done in a workmanlike manner. [ANSI C80.3 Sec. 5.4] |

Protective coating for corrosion resistance:

- The exterior surface shall be either thoroughly and evenly coated with metallic zinc or protected with an ACRC.

- The interior surface shall be protected by a zinc or an organic coating. The interior coating shall have a smooth continuous surface.

An occasional variation due to uneven flow of coating shall be acceptable. [ANSI C80.3 Sec. 5.6]

Identification: Electrical metallic tubing shall be marked “EMT”, in letters not less than1/8-inch (3 mm) high, and with the manufacturer’s name, trade name, or trademark or other descriptive marking by which the organization responsible for the product can be identified. A traceable code can be used to identify the manufacturer when a private labeler uses its own brand or trademark on the product.

[ANSI C80.3 Sec. 6.4 & 9.1]

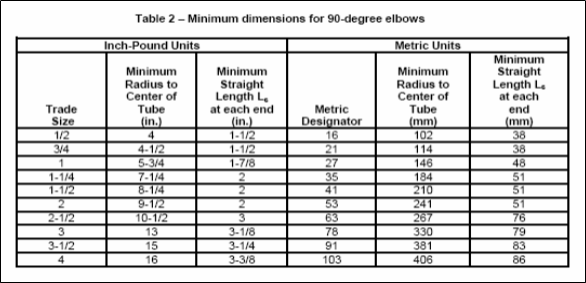

| Dimensions: The dimensions and weight of steel EMT shall be in accordance with Table 1 (Attachment 1). [ANSI C80.3 Sec. 6.5] |

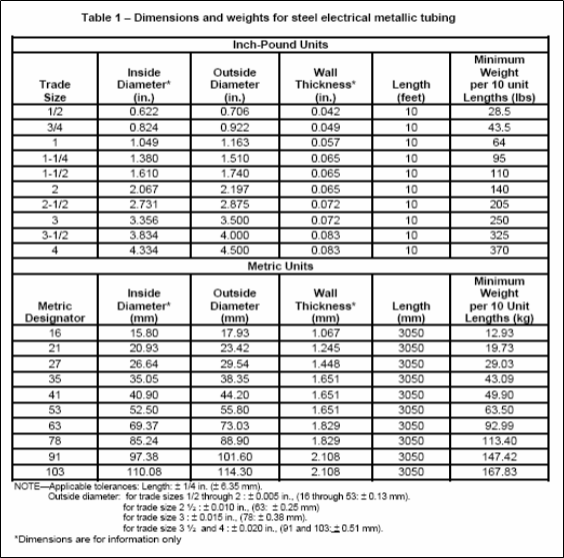

| Elbows: Elbows shall be made of a grade of steel similar to that employed in straight lengths of EMT, and shall be treated, coated, and marked for identification in accordance with the applicable requirements for EMT. The minimum radius of a 90-degree elbow, and the minimum straight length at each end shall be as indicated in Table 2 (Attachment 2). [ANSI C80.3 Sec. 6.6] |

| New and Unused – Electrical materials shall be new and unused. |

| As Designed – Electrical materials shall be in accordance with the Saudi Aramco-approved project-specific design drawings, diagrams, schedules, lists, databases, and associated documents (in particular, raceway type and trade size as shown on electrical BOM and raceway schedules). |

| Free of Damage – Electrical materials shall be free of damage. |

| QC Before Installation – Electrical materials shall conform to all applicable requirements, standards, and specifications prior to release to be used as part of the work. |

| Identification – Electrical materials shall be identified by using tags, stamps, color coding, stencils or labels. The location and method of identification shall not affect the function or quality of the materials. |

| Traceability – Electrical materials shall be traceable from the manufacturer and supplier through delivery, storage, fabrication, erection, installation, repair, modification and use. |

International Codes & Standards

| 3. ANSI C80.3 – American National Standard for Steel Electrical Metallic Tubing (EMT) |

| 4. SAES-P-104 – Wiring Methods & Materials |

| 5. SAES-P-100 – Basic Power System Design Criteria |

Table 1 – Dimensions and Weights for Steel Electrical Metallic Tubing – ANSI C80.3

Table 2 – Minimum Dimensions for 90-Degree Elbows – ANSI C80.3