This article is about installation of Fire water pump skid, it’s operation, manual and procedures.

Fire Water Pump Skid Installation, Operation, & Maintenance Manuals

When you are going to purchase fire water pump skid, supplier shall provide the specified number of complete, bound sets of installation, operating, and maintenance instructions. The delivery date shall be as specified in the purchase order and shall precede the delivery of the skid.

- Installation instructions shall include procedures for uncrating, cleaning, leveling and alignment, assembly, and preparation for start-up.

- The equipment installation information shall be provided for incorporation into a separate installation specification or dossier. The installation specification shall cover all of the following:

- Setting the equipment on foundation.

- Receipt and installation of all equipment components and associated documents.

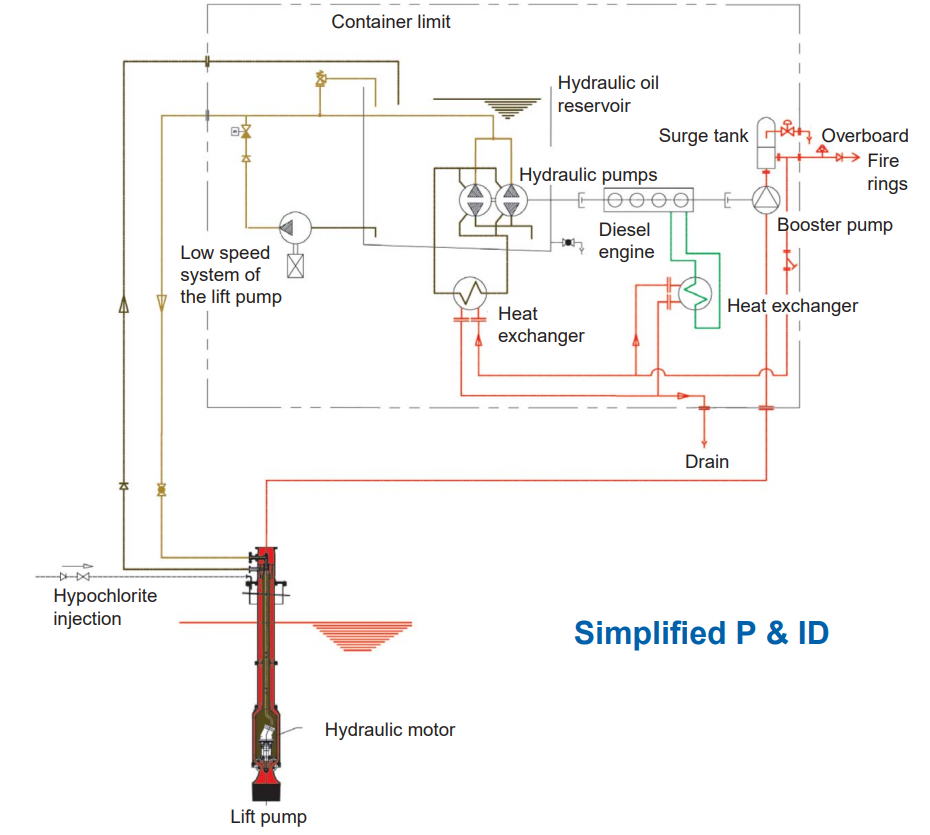

- Assurance that P&IDs agree with installed equipment.

- Removal of preservative.

- Flushing and cleaning.

- Equipment shafts rotate freely when rotated by hand.

- Electrical leads are connected to rotate motor in correct direction.

- Alignment.

- Connections to process and utility services.

- Inspection.

- Acceptance.

- Operating instructions shall be provided in sufficient detail to instruct a technician in how to prepare the machine for operation (valve and control positioning, lubrication, before operation checks), how to start the machine (loading, warm-up, as applicable), how to operate the machine (normal operating adjustments, pressures, tabulated normal operating conditions), and how to shut down the machine (valve and control positioning).

- Operating instructions shall include all necessary precautions to be observed to prevent injury to personnel or damage to the equipment.

- Instructions shall include a troubleshooting table presenting possible troubles that might develop, the probable causes of the troubles, and the appropriate remedies.

- Specific characteristic curves for the equipment provided marked for the designated operating point and rated conditions shall be included.

-

Maintenance instructions shall be provided in sufficient detail to indicate to a technician how to:

- Alter the characteristics of the equipment to increase or decrease capacity.

- Make adjustments to compensate for wear and specify the values and tolerance to be observed in making the adjustments.

- Properly assemble and disassemble thermal- and mechanical-tightened components.

- Replace parts subject to wear or failure.

- Use proper torque values for all major bolting.

- Components and special tools shall be adequately illustrated so that construction details and internal working are described to assist in understanding the operation, adjustment, and maintenance procedures.

- Instructions shall also be provided for storage requirements before and following erection. These shall include the recommended frequency and the materials for the replacement of protective coatings and desiccants. Parts particularly susceptible to damage during shipment shall be identified so they may be inspected on receipt of the material.

- Maintenance instructions shall include a complete parts list for the equipment provided to this specification including sub assemblies, attachments, accessories, special tools, and individual parts. The manufacturer’s part number shall provide positive identification of the part listed. The complete list may be made up of individual sub assembly lists or bills of material. Any such lists shall be identified by a master list so that each part is identifiable as a component of the main equipment. The parts list shall specify the quantity of each item used in the assembly or component.

- Common hardware items shall be completely described. This provision applies whether or not a hardware item has a part number.

- The parts list shall be supported by detail drawings, cross-sectional drawings, exploded-view drawings, or other illustration material identifying each part and keying it to the parts list so that each item in the list can be located on the illustrations. Items that cannot be procured separately, such as matched sets of gears and pressed-fit items, must be clearly identified.

- The complete parts list shall carry notations indicating which items are recommended for spares by the manufacturer.

- A separate price list shall be provided reflecting current prices for all recommended spare items.

- If publications are provided that cover more models of equipment than actually provided, the supplier shall completely annotate such published material to strike out references, illustrations, and data pertaining to any irrelevant equipment.

- All literature shall be certified as accurate and complete. All literature shall be revised to incorporate the last change or modification performed before closing of the purchase order and final payment.

- All material provided by the supplier shall be reproduced in a manner resulting in clear and legible text and illustrations. It is preferred that material submitted be reproduced on 208 by 297 mm (A4) or 8 1/2 by 11 in paper with flowsheet and similar items requiring greater length reproduced as 297 mm or 11 in-high foldouts.

- All literature shall be marked with ”Company Name” equipment purchase order number and project (charge) number. In addition, when the purchase order requires that the equipment be tagged, the items of literature shall also be marked with the tag numbers.

Fire Water Pump Skids used in Process Gas Facilities

Following keywords need to explain, if you have knowledge about these following please send to us related article.

- Fire pump operation and maintenance manual.

- Fire fighting pump sequence of operation pdf.

- Fire pump testing checklist.

- Fire pump testing procedures.

- NFPA fire pump testing forms.

- NFPA fire pump testing requirements.

- Fire fighting pump sequence of operation ppt.

- FM global fire pump testing and maintenance checklist.

- General fire pump spain pdf.

- Fire fighting panel circuit diagram.

- Schematic diagram fire pump system.

Schematic diagram fire pump system - Fire sprinkler pump pressure.

- Fire hydrant control panel wiring diagram.

- Fire pump testing checklist.

- Water pump inspection checklist.

- Fire pump testing flow chart.

- Fire hydrant system checklist pdf.

- Fire pump testing training.

- Fire pump acceptance test checklist.

- Cummins fire power.

- Diesel engine fire pump specification.

- Fire pump installation.

- SOP for fire pump operation.

- Monthly fire pump churn test form.

- Jockey pump.

- Fire fighting pump types.

- Fire fighting pump room drawing.

- Fire pump catalogue.

- Kirloskar fire fighting pumps catalogue pdf.