1.0 PURPOSE

2.0 SCOPE

3.0 APPLICABLE DOCUMENTS

4.0 RESPONSIBILITY

5.0 MANPOWER

6.0 TOOLS & EQUIPMENT

7.0 METHODS/PROCEDURES

8.0 QUALITY CONTROL

9.0 SAFETY PRECAUTION

10.0 ATTACHMENTS

1.0 PURPOSE

This method statement will serve as a minimum guideline to carry out the Modification of support (full pad repair) activities for plants and refinery projects in accordance with Project Drawings and Specifications.

2.0 SCOPE

This method statement will cover the minimum requirements for Modification of support (full pad repair) to be applied at the site for plants and refinery projects.

3.0 APPLICABLE DOCUMENTS

3.1 Project Specification and Standards

3.1.1 S-000-13A0-001 Supplementary Specification for External Coating

3.2 ARAMCO Specification and Standards

3.2.1 SAEP-302 Instruction for Obtaining a Waiver of a Mandatory Saudi ARAMCO Engineering Requirements

3.2.2 SAES-L-105 Piping Material Specifications

3.2.3 SAES-L-310 Design of Plant Piping

3.2.4 SAES-L-350 Construction of Plant Piping

3.2.5 SAES-W-011 Welding Requirements for on Plot Piping

3.2.6 SAES-H-101V Approved Saudi Aramco Data Sheets-Paint and Coatings

3.2.7 SAES-H-102 Safety Requirements for Coating Applications

3.2.8 Schedule Q Saudi Aramco Project Quality Requirements

3.2.9 Schedule G Material, Tools, and Equipments

3.2.10 Schedule D Safety, Health and Environmental Requirements

3.2.11 SATIP-L-350-1 On-Plot Metallic Piping Installation (Excluding Brazed Piping)

3.2.12 SAIC-L-2018 Inspection of Pipe Support and Pipe Anchor Installation

3.3 Latest Revision of the following Documents shall be used

3.3.1 Latest Approved Drawing

3.4 Saudi ARAMCO Safety, Health and Environmental Standard

3.4.1 Construction safety manual

3.4.2 General Instructions (G.l’s) at the work site

4.0 RESPONSIBILITY

4.1 Construction Manager shall implement HSE requirements for the job and shall study, analyze and schedule all construction activities with his department to include manpower and equipment line up as well as other possible resources required for the successful implementation of the construction work activities. He shall study all aspects of work procedure as per Technical Scope of Work and Saudi Aramco Standards.

4.1 Piping Superintendent shall assist Construction Manager in the overall construction activities. Receives and carries out directives and strategies of Construction Manager in various phases of duties assigned by his immediate Supervisor.

4.2 Piping Supervisor shall study and review all necessary documents for the erection works in his area to include, technical scope of work, specification, bill of quantities, planned milestone dates and construction procedure in support to his Piping Foreman.

He shall monitor the availability of materials in accordance with the schedules and construction analysis. He shall be directly reporting to the Piping Superintendent. He shall coordinate with other discipline to visualize possible conflicts in the drawings as well as in the schedules to provide other options in preventing unnecessary delays and obstructions.

4.3 The Welding Supervisor and/or Foreman are solely responsible to ensure that all welding works are in conformance with applicable codes, standards, specifications and approved procedures.

4.4 Piping Foreman shall be responsible for the direct work supervision at site and ensure that the work is performed in accordance with JV Technical Scope of Work and latest approved for construction drawings. He shall monitor the availability of materials in line with his required schedule.

4.5 Painting Foreman Responsible for carrying out works in accordance with the method statement and project specification and standards.

4.6 QC Inspector shall be responsible in monitoring and inspection of the work and ensures that the work is performed and properly documented in accordance with Technical Scope of Work and Saudi Aramco Standards.

4.7 Safety Officer shall be responsible in monitoring safety aspects and ensuring that the work is done in accordance with DEC/JGC Safety Standard Procedure and Saudi Aramco CSM. He shall discuss to the workers the characteristics of related materials and status of work area giving reminders as an additional point to injury and incident free environment.

5.0 Manpower

5.1 The Piping Superintendent shall control the overall activity he shall be directly reporting to the Construction Manager. The basic manpower under him shall consist but not limited to the following:

5.1.1 Piping Foreman

5.1.2 Welding Foreman

5.1.3 Pipefitters

5.1.4 Welder

5.1.5 Helper

5.2 Safety Officer

5.3 QC Inspector

6.0 TOOLS AND EQUIPMENT

6.1 Tools and equipment needed should be in good condition and must be checked by Supervisor / Safety Officer prior to use in the construction area. These includes but not limited to:

6.1.1 Paint brush / roller

6.1.2 Welding machine .

6.1.3 Straight edge

6.1.4 Magnetic/spirit level

6.1.5 Grinder

6.1.6 Steel brush

6.1. 7 Welding Outfit

7.0 METHODS/ REPAIR PROCEDURES

7.1 Prepare materials needed for the job.

7.2 All materials or tools must be in good condition.

7.3 Modification of support (full pad repair)

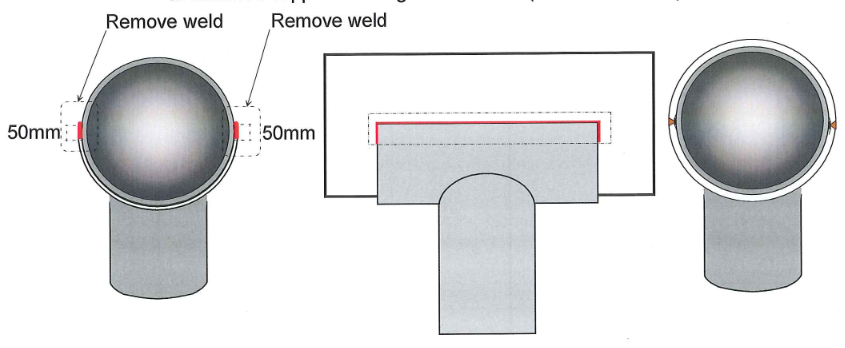

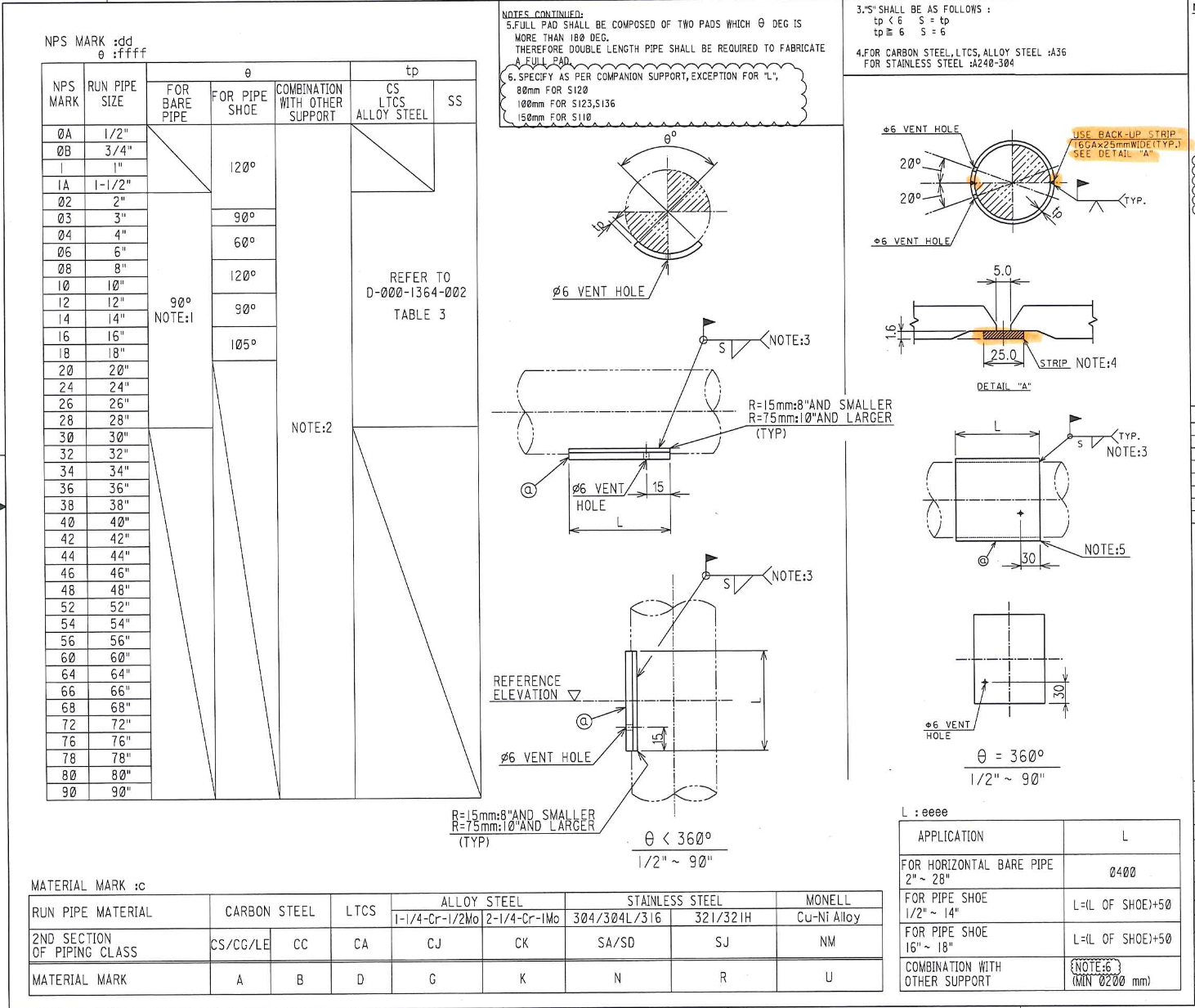

7.3.1 Remove weld on support atleast 50mm from tip of pad by means of grinding to insert the required back-up strip. Refer to illustration below for details and refer to attached support drawing for reference (D-000-1364-120).

7.3.2 After removal of weld, conduct MT for ferromagnetic pipes and PT for non ferromagnetic pipes (Ref. SAES-W-011 para. 17.5.3). After MT or PT, UT shall be applied to check the thickness of the ground surface of the pipe. If any grinding reduces the base metal thickness to less than the design minimum, the ground area shall be rewelded and ground flush with the original base metal surface or the component shall be replaced. Rewelding shall be done only with the pior approval of Saudi Aramco Inspection. (Ref. SAES-W-011 para. 11.8)

7.3.3 If grinded part has no damage, install back-up strip then. fit-up as per approved WPS. Refer to S120 pad for details of full pad (D-000-1364-120).

7.3.4 After acceptance of fit-up proceed to full welding as per approved WPS.

7.4 Touch-up paint

7.4.1 Surface preparation and coating shall be in accordance with the SAES-H series standards, related 09-SAMSS series specifications and this project specification. The work shall result in properly coated surfaces free from pinholes, voids, skips, runs, sags, thin spots, dirt and abrasive inclusions, and other evidence of poor workmanship.

7.4.2 Prior to any mechanical/hand tool cleaning; oil, grease, paint and other surface contaminants shall be removed from steel.

7.4.3 All touch-up and repair of coated surfaces at construction site shall follow Table A of this specification of S-000-13A0-001.

7.4.3.1 All repaired, reworked, damaged steel supports will be coated as per the applicable coating schedule.

7.4.3.2 Touch up application shall be done using brush/roller.

7.0 QUALITY CONTROL

7.1 All Testing and Inspection shall be coordinated with Inspector.

7.2 QC Inspector shall be assigned to ensure the quality control and assurance requirement of the project.

7.3 QC Inspector shall be responsible to conduct all required inspection / documentation and to ensure that all applicable requirements, codes, and standards are complied with.

7.4 Contractor has to utilize the applicable inspection and test form reflected on approved SATIP.

8.0 SAFETY PRECAUTION

8.1 Obtain necessary work permits from the concerned Representative intended for the job before starting any work.

8.2 Conduct proper preparation to include required safety equipment and tools for the commencement of the work.

8.3 Activities shall be executed in accordance with this procedure and related standards and specifications.

8.4 Provide warning sign and sufficient barricade on working area. Only assigned personnel will be allowed in the area to maintain a safe work environment.

8.5 Conduct safety briefing to all working crew to remind them of all the basic safety requirements on the job to ensure safe work flow.

8.6 Continuous monitoring and inspection shall be implemented by the site supervisor/foreman together with the assigned safety officer in the area. Any unsafe practices while performing the work activities shall be corrected immediately to avoid stoppage of the work and provide action plan on how to eliminate unsafe works ..

8.7 Good housekeeping shall be maintained throughout the work activity. The work site shall be kept clean and safe.

8.8 Safety Officer shall monitor the work activities to help and protect all assigned workers against exposure to safety hazards. He shall ensure that Personal Protective Equipments (PPE’s) are supplied and worn at all times.

8.9 Safety Supervisor to support his safety officer in implementing safety matters on this project and he shall ensure to provide action plans on how to eliminate hazards.

9.0 ATTACHMENT:

Attachment 1: Job Hazard and Risk Assessment (JHRA)