1. SCOPE

2. REFERENCES

3. GENERAL

4. SAFETY

5. MATERIALS

5.1 Alloys

5.2 Gases for Weld Backup

6. METHODS OF INTRODUCING BACKUP GAS

7. PURGING

8. GAS BLANKETING FOR TANTALUM AND OTHER HIGHLY REACTIVE METALS

9. RATE OF FLOW OF BACKUP GAS

10. JOINT DESIGN

FIGURE

- Withdrawable Plug

- Purge and Vent Through Blanks

- Withdrawable Chamber

- Purge Distributor Ring

- Balloon Type Plugs

- Hypodermic Needle Purging

- Backup Channel

- Purge Distributor Pipe

- Controlled Atmosphere Welding Chamber

- Trailing Shields for Circumferential Welds

- Trailing Shield

- Trailing Shield Controlled by Welder

- Typical Shields

- Typical Shielding Arrangements

- Chill Clamps and Shield for Butt Welding Tubing

- Setup for Welding Flange to Tube when Underside is not Accessible

- Setup for Welding Flange to Tube when Underside is Accessible

- Gas Shield and Jig for Small Tubing

Gas Shielding, Weld Purging, and Backup Techniques

1. Scope

1.1 This Article provides information on the use of gas backup, shielding, and purging for gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW) of sheet, plate, and pipe.

1.2 This article pertains to the use of gases for backing up the reverse side of weld joints in addition to the argon or helium in the welding torch for shielding the arc and for generally improving protection of hot metal from contamination by the atmosphere.

2. References

Reference is made in this standard to the following document.

3. General

3.1 Gas backup is provided when welding pipe, or sheet or plate where the joint is accessible from only one side. The backing gas protects the underside of the weld and the adjacent base metal surfaces from oxidation during welding. The oxide coating prevents or inhibits wetting, flow, and coalescence. Complete weld penetration, uniformity of root bead contour, freedom from undercutting, and the desired amount of root bead reinforcement are more likely to be achieved when using gas backup under controlled conditions. In some materials, gas backup reduces root cracking and porosity in the weld. Careful control of joint geometry, welding technique, and gas flow is required for maximum benefit from the use of gas backup.

3.2 Gas backup during tacking allows the coalescence of tacks into the weld. Otherwise the tacks need to be removed for welds free from caulk of fusion defects.

3.3 Gas backup shall be used with the consumable backup strip (EB) technique.

3.4 Gas backup is employed with GTAW and GMAW. When the first bead is deposited by GTAW process in conjunction with gas backup, and subsequent beads are deposited by SMAW process, the gas backup shall be maintained until the bead is completed if surface oxidation cannot be tolerated.

4. Safety

Safe practices prescribed in SES W02-F01 shall be followed on plant sites.

5. Materials

5.1 Alloys

Gas backup may be employed advantageously in welding alloy steels, aluminum, copper and copper alloys. Gas backup is used when welding all other nonferrous materials for proper metal coalescence. Gas backup to an extreme is mandatory in welding titanium, tantalum, columbium, and zirconium, since absorption of atmospheric oxygen and nitrogen in the weld metal results in brittle welds, and loss of corrosion resistance. See further description in section 8.

5.2 Gases for Weld Backup

5.2.1 Argon or helium, 99.9 percent minimum purity, may be used satisfactorily to back up welds in all materials. These gases are expensive.

5.2.2 Nitrogen may be used satisfactorily to back up welds in most austenitic stainless steel and copper and copper alloys. Where gas backup is used on aluminum to minimize weld porosity, argon is more satisfactory than nitrogen.

Nitrogen shall not be used to back up welds in titanium, tantalum, columbium, or zirconium nor the ferritic or martensitic stainless steels or Type 321, 347, or 348 austenitic stainless steels or the high nickel alloys.

5.2.2.1 Where weld discoloration that results from slight surface oxidation is not objectionable, commercial or standard dry nitrogen can be used. Commercial nitrogen has a maximum oxygen content of 0.3 percent and a dew point of minus 60°C (minus 76°F).

5.2.2.2 Where discoloration of the weld bead shall be minimized, the use of high purity (low oxygen content) grades of nitrogen is recommended. Such grades contain 0.002 percent maximum oxygen. As with commercial dry nitrogen, the dew point of these grades is minus 60°C (minus 76°F). Prepurified nitrogen and high purity dry nitrogen that contains no hydrogen comes in cylinders that have a right hand valve thread.

5.2.2.3 Bottled nitrogen costs less than bottled argon and, as bulk liquid, costs much less than the cost of argon.

6. Methods of Introducing Backup Gas

6.1 There are several methods of introducing backup gas into the region of the joint to be welded. Seal adequately around the gas inlet to avoid aspirating air.

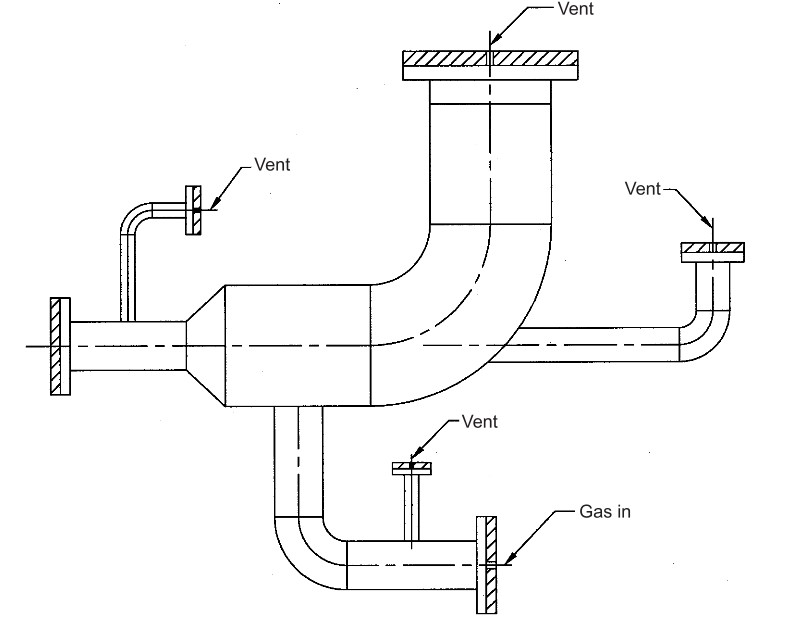

6.1.1 One method which is used in shop fabrication of piping consists of blanking off the flanges or ends of the piping system as shown on Figure 2. Masking tape is often used, but blanks may be made from steel plate, heavy paper, or cardboard. The gas is introduced through one of the blanks and vented through one or more of the other blanks. The gas inlet and venting locations are chosen so that the joints to be welded are located between the inlet and venting locations. It is preferable to admit gas at the lowest position in the system and vent at higher positions. Venting and, to a lesser degree, flow rate shall be correct to eliminate dead air pockets in the system.

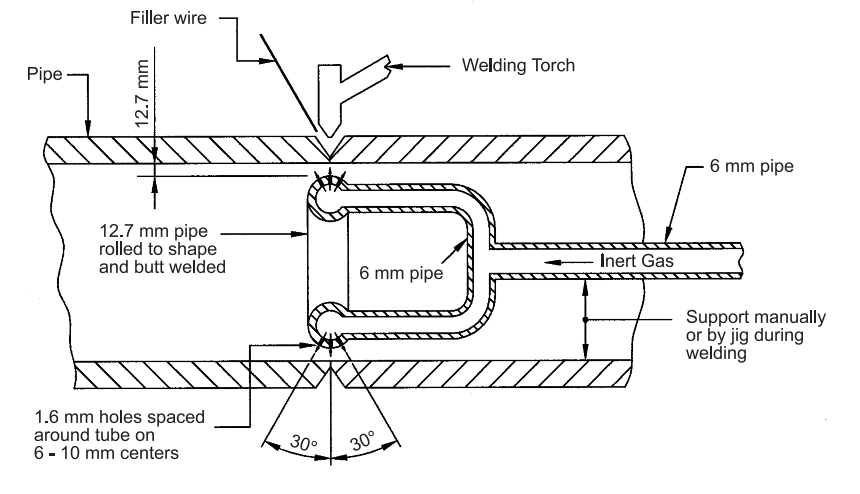

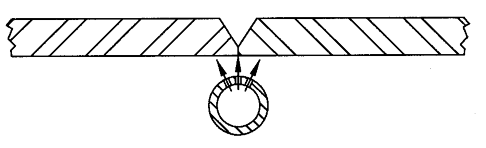

6.1.2 Another method of providing gas backup for pipe welding is shown in Figure 1. It consists of inserting withdrawable plugs into the pipe assembly on one or both sides of the joint to be welded, so as to restrict the volume that shall be purged from beneath the joint.

FIGURE 1 – Withdrawable Plug

FIGURE 2 – Purge and Vent Through Blanks

6.1.3 A third method of introducing backup gas, as shown in Figure 3, involves the use of a withdrawable isolating chamber device which can be inserted into the piping assembly beneath the joint to be welded.

FIGURE 3 – Withdrawable Chamber

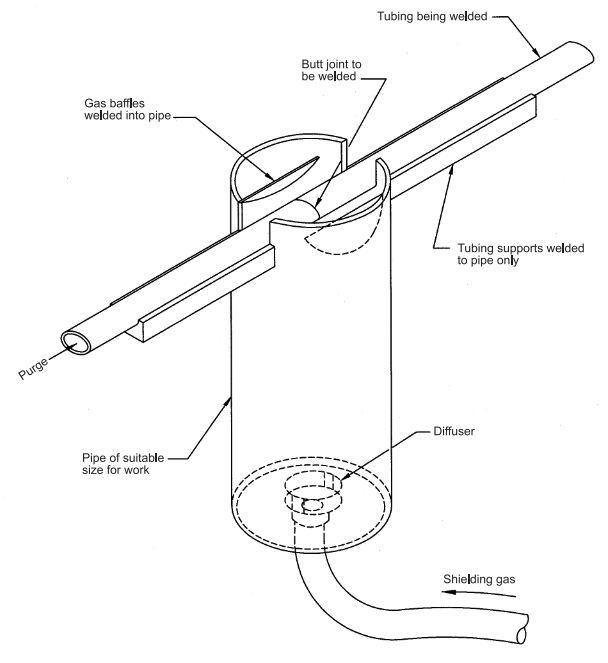

6.1.4 A method which can be used for backing up welds in large diameter pipe, for example 305 mm (12 in) or over, is shown in Figure 4. It consists of placing beneath the joint a ring made of small diameter pipe and containing numerous small holes around the periphery. This arrangement distributes the gas to the under surface of the joint.

FIGURE 4 – Purge Distributor Ring

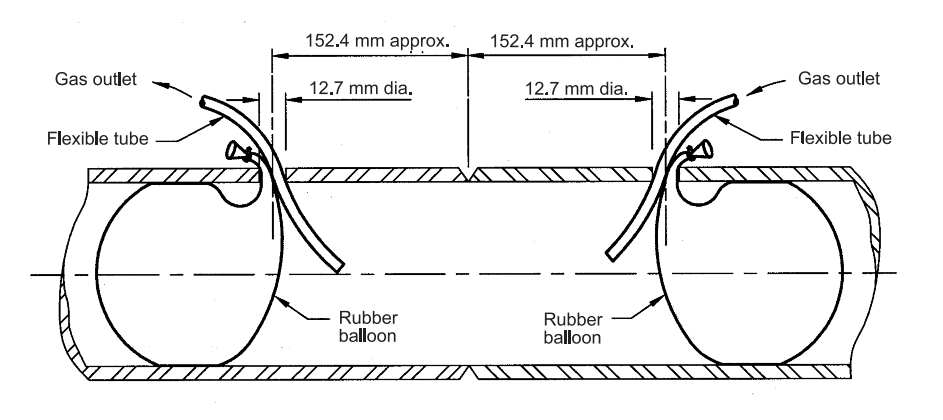

6.1.5 Another method of gas backup which has been proposed for field use in final closing pipeline welds is shown in Figure 5. This method consists of drilling a small hole of 12.7 mm (1/2 in) in diameter through the pipe wall on both sides of the joint to be welded. A rubber balloon and a length of flexible tubing are inserted through each hole into the pipe. The balloons are inflated, thus blocking off the rest of the system. One tube provides for gas inlet, and the other serves as a vent to prevent excessive pressure build-up. After completing the weld, the balloons and tubes are withdrawn, and the drilled holes are plug welded.

FIGURE 5 – Balloon Type Plugs

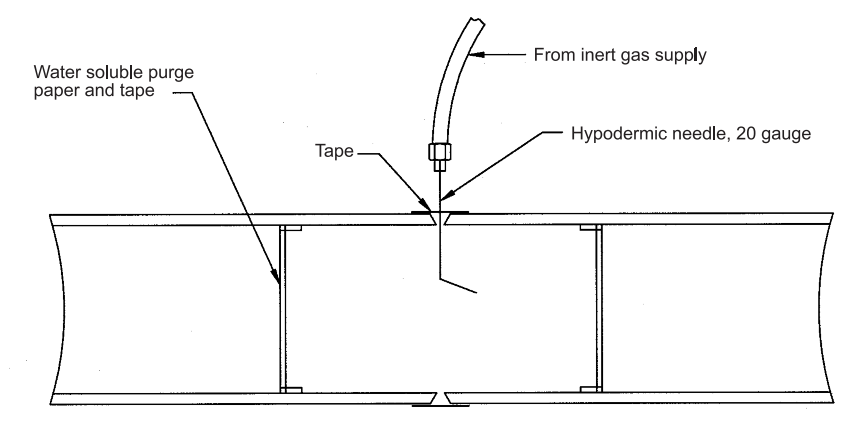

6.1.6 Where water may be used after welding, dams made from water soluble paper and tape may be used and flushed out after welding is complete. See Figure 6. In this scheme the inert gas is introduced through a large bent hypodermic needle, which is inserted through the top of a tape covering the joint root. The weld root is made as the tape is peeled back leaving approximately 25.4 mm (1 in) of tape at the needle. One filler pass over the root pass is completed to this point, then the needle and tape are removed, then the root and filler pass are completed as soon as

possible. Follow the manufacturer’s directions for flushing out the water soluble dams. A frequent problem in applying this system is the need to control humidity of the tape to retain its stickiness.

FIGURE 6 – Hypodermic Needle Purging

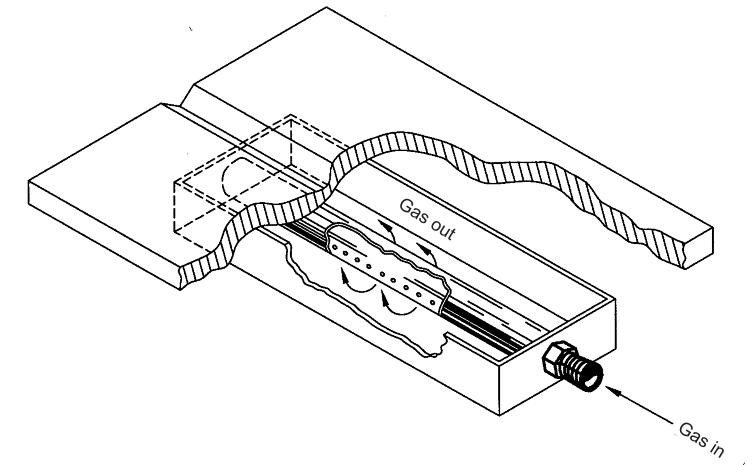

6.1.7 In welding sheet or plate, the backup gas may be introduced through a channel held beneath the joint as shown in Figure 7. The channel is covered at both ends, and gas is admitted through the perforated pipe. Gas is vented through the weld joint and the unsealed edges of the channel.

FIGURE 7 – Backup Channel

6.1.8 Another method for backing up sheet or plate with gas during welding uses a length of pipe having numerous small holes that is placed beneath the joint as shown in Figure 8. The holes in the pipe are located so as to distribute the purging gas over the under surface of the joint.

FIGURE 8 – Purge Distributor Pipe

7. Purging

7.1 Where the method employed causes a large volume of air beneath the joint to be displaced, it is necessary that the system be adequately purged before welding is started. Ordinarily, this requires passing through the system a volume of backup gas equal to at least three times the volume of the system. More than three volumes is required if the system cannot be vented easily, or if weld discoloration cannot be tolerated. The backup gas shall enter the system at a low point and be vented to the atmosphere at points beyond the joint to be welded.

7.2 In piping systems which have several joints, all except the one being welded are sealed with masking tape. When this weld has been completed, the tape is removed from the next joint to be welded, and so on.

8. Gas Blanketing for Tantalum and Other Highly Reactive Metals

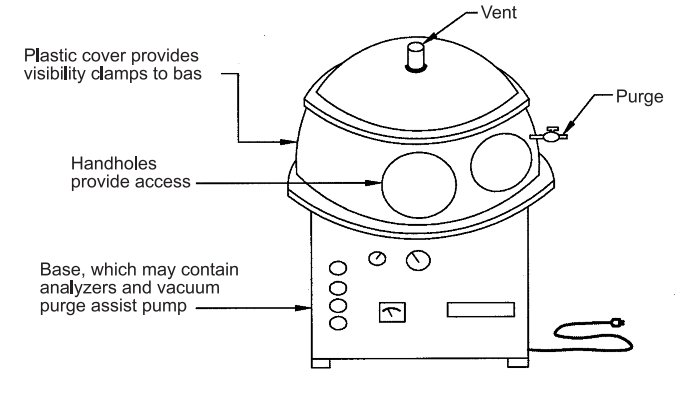

8.1 Maximum benefits can be obtained when the entire object to be welded can be placed in a controlled atmosphere chamber. Such chambers, as shown in Figure 9, have provision for containing the pieces to be welded in a plastic ‘bubble’, or in a box containing sight glasses, and glove ports. After the parts have been put in the chamber, purging is begun, and readings can be taken on oxygen analyzing instruments to assure that welding does not start until oxygen content is at a suitably low level, usually less than 50 ppm.

FIGURE 9 – Controlled Atmosphere Welding Chamber

8.2 When size, configuration, or location of welds to be made preclude welding in the chamber, as described in 8.1,‘bag’ welding may be done. In this technique, the weld job is enclosed in a clear vinyl plastic bag, 4 – 6 mils thick. The atmosphere in the bag is evacuated, and the ‘bag’ or ‘pillow’ is inflated with argon. The gas tungsten-arc torch is introduced through a small slit which is cut in the top of the bag, and the weld is effected in the argon atmosphere. The sequence is as follows:

a. Properly flanged parts are mated to ensure that the flanges are in contact throughout the joint.

b. Clean and reassemble the joint, being careful not to touch the welding areas with bare hands. Clip the flanged joint together at frequent intervals with ‘junior sized’ vise grip pliers.

c. Using optical quality 4 – 6 mils thick vinyl plastic sheeting, construct a bag or pillow large enough to contain the clamped up joint easily. Tape the edges together with 50.8 mm (2 in) wide cloth tape to make an airtight seal.

d. Plan the job so that all traces of atmosphere may be exhausted from the bag, being replaced with a continuous argon purge. Small weldments can be contained in the bag with ground cable and argon hose taped through the bottom wall of the bag. Sometimes it is convenient to attach a hose to a length of copper tubing which then can be used to convey both argon and ground current through the bottom wall of the bag. Long pipe or tube weldments which project through the bag shall be sealed at the ends, and completely purged with argon before welding commences. The weld is made easily when the weld surfaces are chemically clean and completely surrounded with argon. The continued flow of purge gas during welding, as in 9.1, escapes through the pipe and thus prevents air from entering.

e. Cut a 25.4 mm (1 in) long slit in the top of the plastic bag, permit gas to flow long enough to purge all traces of atmosphere from the argon filled bag, then insert and tape in place the head of a small GTAW torch to reach the weldment. A foot control to start and stop the welding current is very helpful. After tacking the joint, the vise grip pliers may be released and dropped in the bag to permit completion of welding.

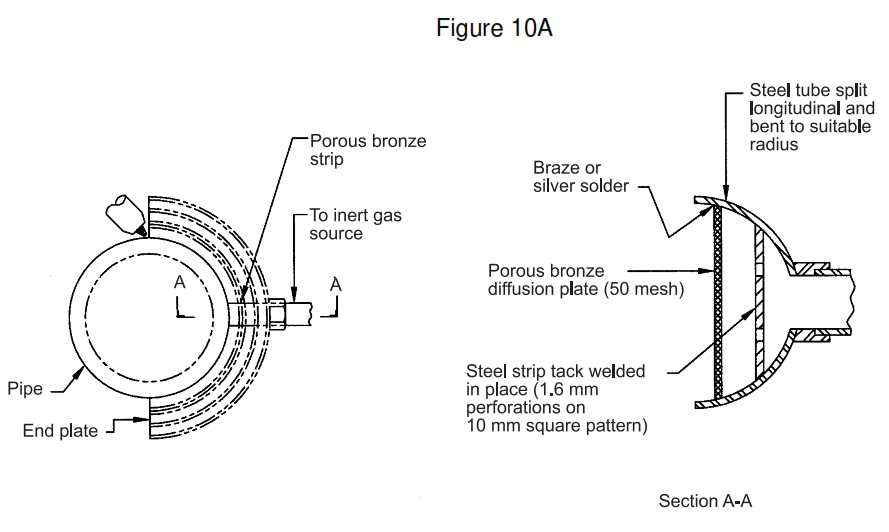

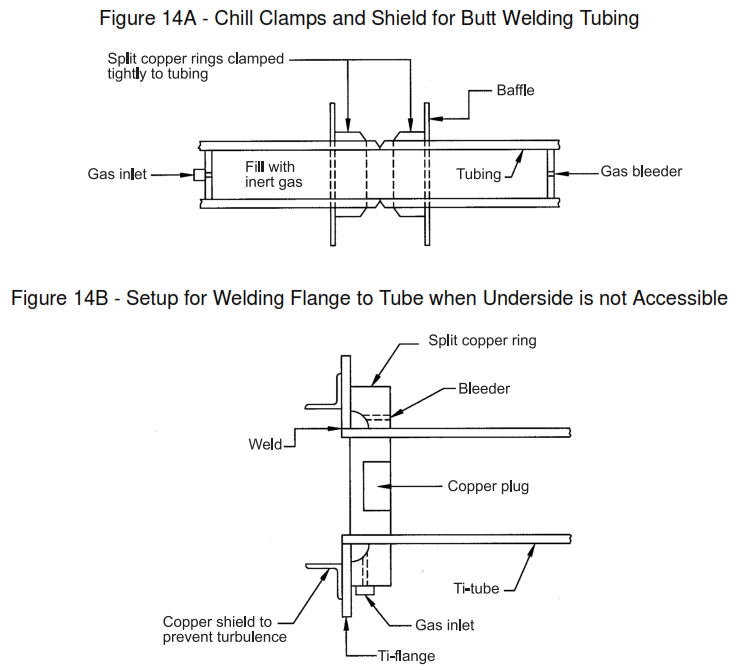

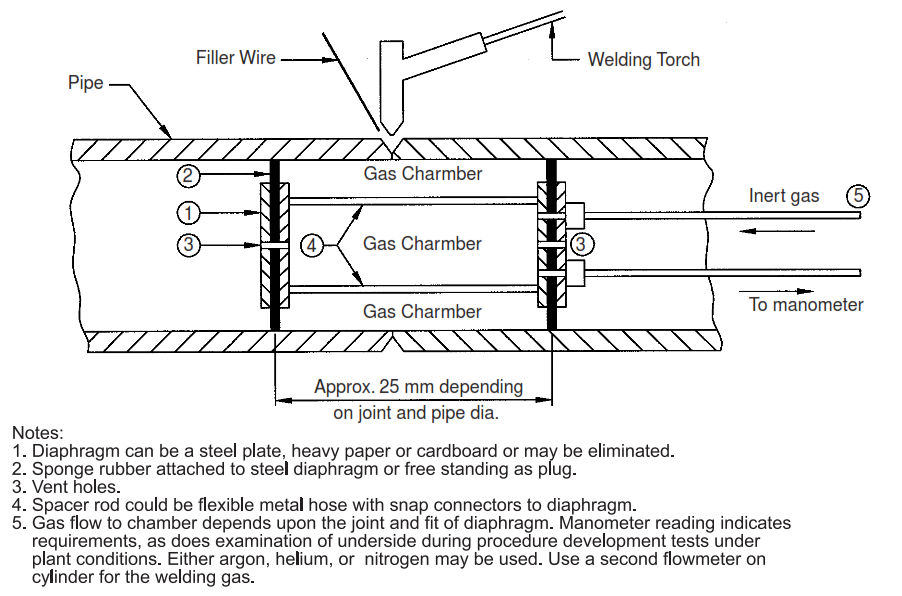

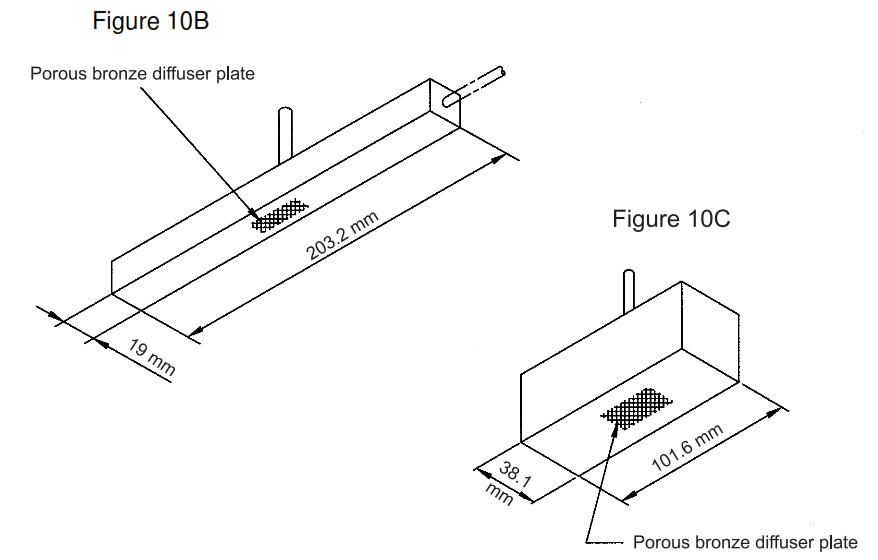

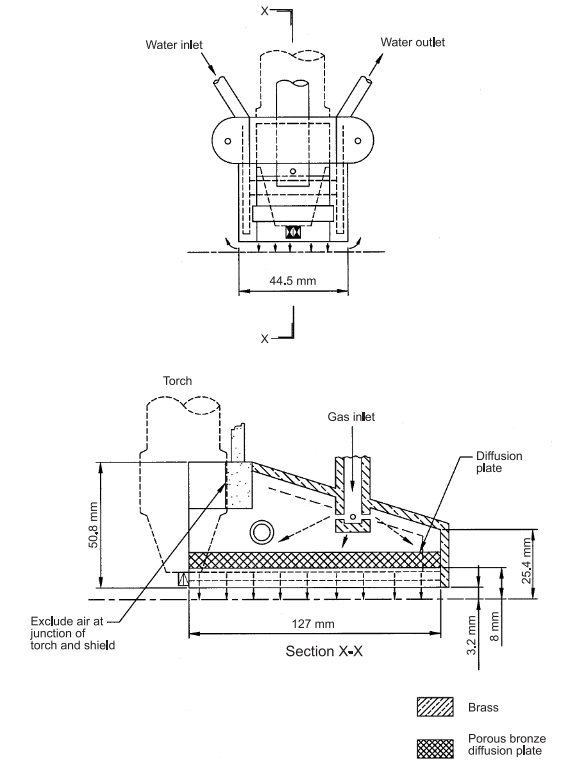

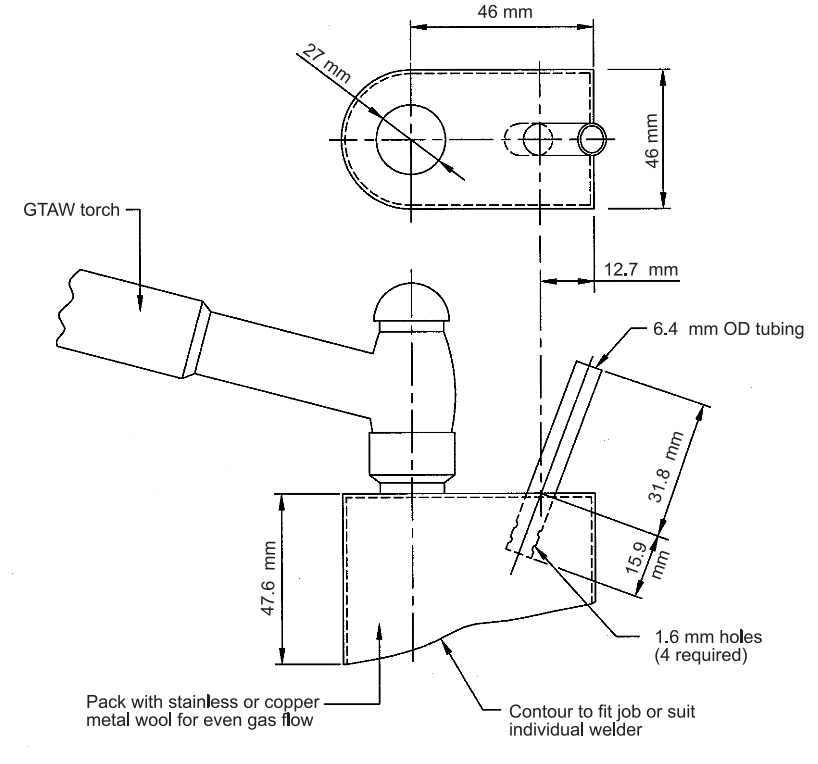

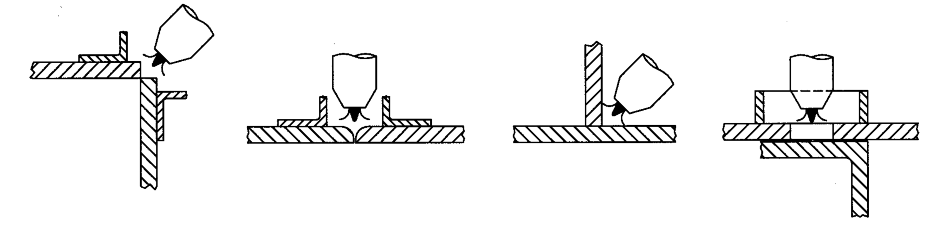

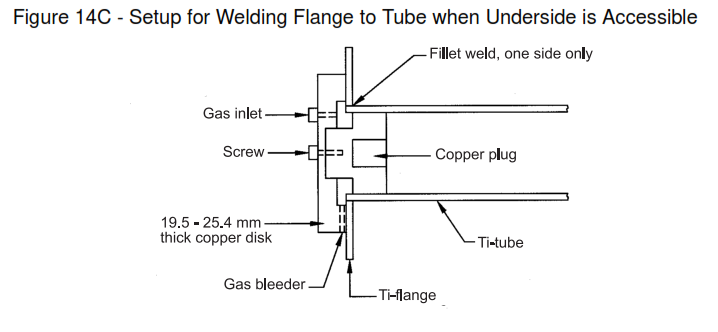

8.3 Trailing shields are necessary when chambers or ‘bagging’ techniques are not feasible. Trailing shields are shown in Figures 10 and 11 for circumferential and straight joints respectively. A third type of trailing shield is shown on Figure 12. Appropriate gas backup as described in section 6 is used in conjunction with each of these shields. Fixed barriers as illustrated on Figure 13 also aid in shielding the area immediately surrounding the torch. Other typical shielding devices for use in pipe butt joints and welding flanges to pipe are illustrated on Figure 14. A combination gas shield and jig to hold small tubing is illustrated in Figure 15. Most of these devices restrict the welder’s view of the weld and

require some practice to develop proficiency.

FIGURE 10 – Trailing Shields for Circumferential Welds (Keep Dry)

FIGURE 11 – Trailing Shield (Keep Dry)

FIGURE 12 – Trailing Shield Controlled by Welder (Keep Dry)

FIGURE 13 – Typical Shields

FIGURE 14 – Typical Shielding Arrangements

FIGURE 15 – Gas Shield and Jig for Small Tubing

9. Rate of Flow of Backup Gas

9.1 After purging is completed, the flow of backup gas during welding shall be reduced to a point where only a slight positive pressure prevails. However, during purging the rate of purging varies inversely with the gas flow rate.

9.2 Provision of an adequate vent is important to prevent excessive pressure build-up during welding. The area of vents through which the backup gas is exhausted to the atmosphere shall be at least equal to the area of the opening through which the gas is admitted to the system. The location of vents shall be selected to direct purge paths to effectively purge the areas that are subject to heat input.

10. Joint Design

For accepted joint designs, refer to a SES ‘W’ discipline ‘F’ category standard which describes the welding process

and the fabricating materials respectively.