There are various types of metallurgical damages which are associated with the operation at high temperature in aggressive environment. Almost all of the metallurgical degradations take place progressively depending upon operating temperature, length of exposure, and metallurgy of exposed metal.

Unless the damaging environment is not restricted in one area, the damage in all of the metallurgical degradations is usually wide spread over large areas. Most of the damages can be predicted with timely inspection using appropriate inspection techniques like eddy currents, back scattered ultrasonic spectroscopy, and metallographic replicas. Out of all the inspection techniques the metallurgical replica is the most reliable techniques to accurately assess extent of damage.

High Temperature Corrosion Explanation & Types.

There are numerous kinds of metallurgical degradation damages which highly depend on the process conditions and compatibility of the affected metal to these conditions. Following text outlines most commonly found metallurgical damages in process industry.

1. Creep/Stress Rupture.

Creep is the metallurgical damage caused due to exposure of the metal under tensile stress, at high temperature for prolonged period of time. Micro- voids are formed at the location of the stress at high temperature.

The failure takes place well below the minimum yield strength of the material due to the micro‐voids. The main controlling factors in creep deformation are material creep resistance, temperature and the magnitude of load. The susceptible materials include the tubes in furnaces, heaters, catalytic reformer reactors, and the piping carrying high temperature fluids. The most of the creep failures initiate at the Heat Affected Zones (HAZ) of welds.

Similarly the welds joining dissimilar materials also suffer creep damage due to differential thermal expansion stresses. Earlier stages of the creep can be detected by the metallurgical replicas. While later stages can be detected any the conventional NDT methods.

Further details on this damage mechanism can be seen from API‐RP‐571 Para 4.2.8.

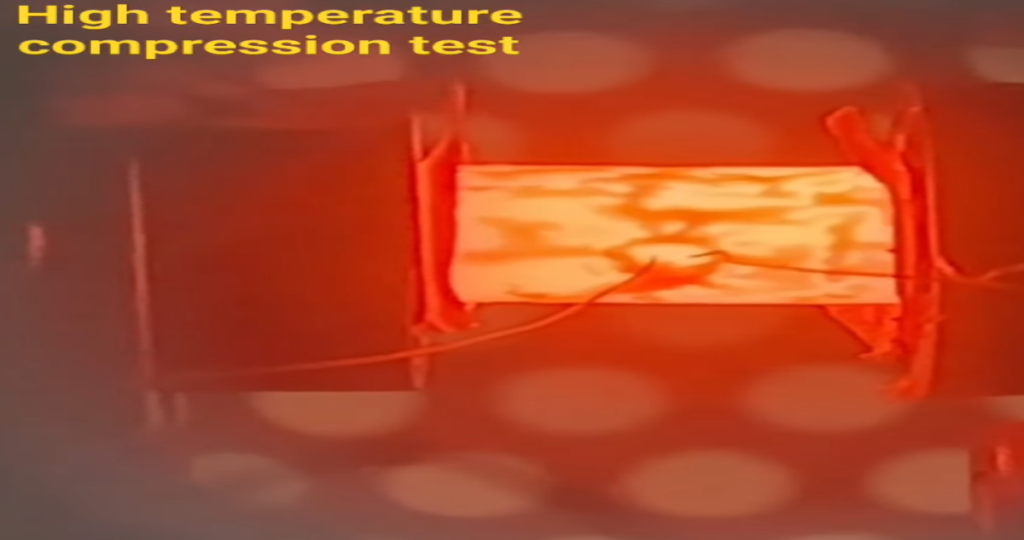

2. Thermal Fatigue and short term overheating.

Thermal fatigue and short term overheating are similar kind of damage mechanisms which result reduction in the yield strength and later on failure due to sudden (or cyclic) changes in the temperature. The sudden change in the temperature could be due to shutdown and startup, temperature runaway, gas or liquid quenching etc. Further details on this damage mechanism can be seen from API‐RP‐571 Para 4.2.9 & 4.2.10.

3. Sulfidation.

Sulfidation is the corrosion of carbon steels and other alloys due to the reaction of H2S with Fe resulting in an iron sulfide scale at high temperatures (above 500‐575°F). Sulfidation reaction depends on H2S concentration and temperature. It is one of the major corrosion types attacking sulfur Recovery Unit and normally takes place in the reaction furnace, auxiliary burners, and thermal oxidizer.

Further details on this damage mechanism can be seen from API‐RP‐571 Para 4.4.2.

4. Carburization and Metal Dusting.

Carburization is the migration of the carbon into the metal lattice due to high temperature exposure of metal with the carbon rich atmosphere. The carburization takes place on the inside surface of the in the furnace tubes in catalytic reformers and coker units or other heaters at decoking cycles. Metal dusting is an extreme form of carburization. The carburization results in hardening the upper layer of the metal which causes cracking.

Further details on this damage mechanism can be seen from API‐RP‐571 Para 4.4.3 & 4.4.5.

5. Decarburization.

Decarburization is the reverse process of carburization in which the carbon migrates out of the metal lattice at high temperature. The decarburization caused loss of the creep and tensile strength of material. The decarburization can take place in all kind of steel product in the high temperature service. Most vulnerable are the tubes in the Catalytic reformer and other high temperature furnaces.

Further details on this damage mechanism can be seen from API‐RP‐571 Para 4.4.4.

6. High Temperature Hydrogen Attack (HTHA).

High temperature hydrogen attack takes place due to exposure of metallic surface results from exposure to hydrogen at elevated temperatures. The carbides in the metal lattice reacts with the hydrogen and forms Methane CH4 which cannot diffuse through the metal. The loss of carbides causes the reduction in the overall strength of the material. As the methane pressure builds the cavities are formed which cause cracking in the material like hydrogen blistering.

Further details on this damage mechanism can be seen from API‐RP‐571 Para 5.1.3.1.

7. Other High Temperature Metallurgical Damages.

Some other common thermal damages include Graphitization, Spherodization, temper embrittlement, Strain Aging, 885 oF Embrittlement, and Sigma Phase Embrittlement.