INSPECTION AND TESTING OF VESSEL OR COLUMN

The following items shall be inspected and recorded during and after assembly:

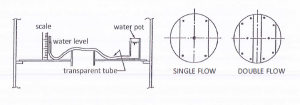

Level of Tray Floor

The level of tray floors shall be checked using manometer hose or its equivalent at least five points (one at middle and four at corners) to each pass.

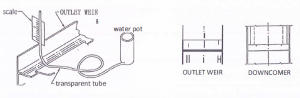

Level of Outlet Weir and Downcomer

The level of outlet weirs and downcomers shall be checked using a manometer hose or its equivalent at three points (both ends and center of outlet weir and downcomers) to each pass.

Dimensional Inspection

In addition to the above, dimensional inspections for the following items shall be made with a manometer hose or its equivalent and steel ruler or suitable gauge against the tolerance stipulated in the vendor’s drawing.

A) Outlet Weir

The outlet weir height from the tray floor shall be measured as three points to each pass. This shall also apply to the measurement of the outlet weir height for the seal pan.

B) Clearance Between the Outlet Weir and Downcomer

The difference in height between the top edge of the outlet weir and the bottom edge of the downcomer shall be measured using a manometer hose or its equivalent at three points both ends and center of outlet weir and downcomer.

Note:

The maximum out-of-level and maximum deviation from the specified height and distance shall not exceed the tolerance given by the vendor.

Visual Inspection

Visual Inspection shall be made for the flatness of tray floor, correct use of clamping devices, etc. Tightness inspection of bolts shall be made using torque wrench (random) or hammering. Final Check and Cleaning.

Final Check

After all inspections are done and the corrective action (if any) has been completed, all assembled trays and other internals shall be checked visually. Cleaning All trays and other internals assembled shall be cleaned, and dirt, loose scale, slag, and any parts of tools, etc., shall be removed from inside of the tower.

All inspections shall be done in accordance with standard.

Leak testing shall be done in compliance to SATR-D-2004.

Installation of tray assembly shall be done in compliance to SAIC-D-2009.

Visual inspection shall be made for the flatness of tray floor.

Correct uses of damp devices, etc. are to be observed.

Bolt tightening inspection shall be done using calibrated torque wrench with valid calibration certificate.

All assembled tray components shall be free of dust and foreign particles prior to box up/final closure.

Equipment preservation shall be decided as the project progresses and shall be done as determined.