This article is about Intrinsically Safe Circuit Final Checking, Inspection Checklist Before Energization Loop

Intrinsically Safe Circuit Final Checking Before Energization I.S Loop

Ensure all Instrument specification sheets for the complete loop are available

The installation Record sheets to be verified and formed as part of loop folder

Ensure that all individual loop components have been calibrated

Aramco Inspection / P&CSD / Proponent , Contractor QC signatures to be verified on installation inspection as well as test / calibration sheets.

Ensure prior permission to use an intrinsically safe system from the General Supervisor, Process Instrumentation Division, P&CSD.

Conform all Material Test Report (MTR) for the entire loop components are available

The Certifying agency, Certificate number, and Date of certification shall be supplied for each component in the intrinsically safe system.

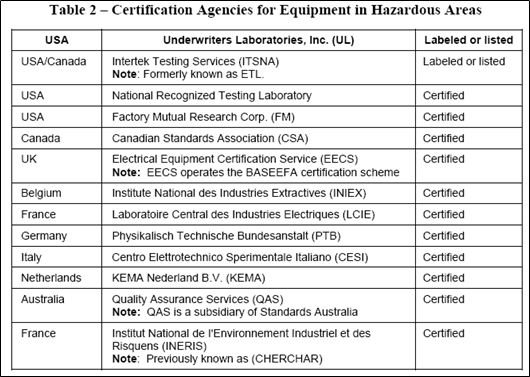

“As third party testing laboratories, only the agencies listed in SAES-P-100, Table 2 are acceptable under this standard. For equipment, devices, or apparatus certified as intrinsically safe, only those

that are certified as category EEX or AEX “”ia”” shall be used.”

Pre-Loop Check – Works Inspection

Ensure that actual field installation is completed in all aspects .

The completed instrument loop shall be tested as one system, and where necessary adjustments shall be made to the calibrations.

I.S. System Design Package: Electrical area classification drawing are available

I.S. System Design Package: Plan drawing showing the overall I.S. system from the instruments in the hazardous areas to the instruments in the non-hazardous area (usually the control room). For sake of clarity, the drawing shall show the I.S. system only. Demarcation lines between the non-hazardous (safe) area and the hazardous area portions of system shall be clearly shown. The respective areas shall be labeled “non-hazardous (safe)” and “hazardous area”

I.S. System Certification Information: The I.S. system control drawing shall reference the applicable Instrument Loop Diagram (ILD) or Instrument Segment Diagram (ISD), ref. SAES-J-005.

“Cable/Wire Information: Size of individual pair or triad, capacitance per unit length, and inductance per unit length.

Exception: Multiconductor “”home run”” cables may be specified with 18 AWG conductor size.”

Cable/Wire Information: Cable length, meters (feet)

Cable/Wire Information, Insulation Rating: Interconnecting cables shall be specified with a minimum insulation rating of 600 Volts.

Cable/Wire Information: Cable manufacturer

“Grounding Plan:

Overall control building grounding plan,

I.S. system grounding plan for associated apparatus, cable shields, and enclosures.”

Installation, Interconnecting wiring: Cables shall be sealed against the passage of gas and vapors as required by the National Electrical Code NFPA 70, SAES-B-008, and SAES-O-126.

Identification: All intrinsically safe system components shall be so identified.

Identification: All junction boxes, cable trays, conduits, cables, cabinets, and instrument housings shall be labeled as containing intrinsically safe circuits or equipment. The means of identification shall be visible after installation. Label spacing on cable tray, conduit, and interconnecting cables shall not exceed 25 feet (8 meters).

Identification: Light blue color coding shall be used to identify intrinsically safe wiring. The preferred practice is to specify intrinsically safe interconnecting cables with a blue outer jacket. Alternatively, blue sleeves slipped over the jacket at all points of termination may be used to identify I.S. wiring.

International Codes and Standards used for Intrinsically Safe Circuit

- Intrinsically Safe Circuits Instrumentation, Box and Barrier Installation(Opens in a new browser tab)

- ISA-RP 12.2.02-1996 – Recommendations for the Preparation , Content and Orga. Of Intrinsic Safety Control Drawings, 15 May 1996

- SAES-J-902 – Electrical Systems for Instrumentation, 11 May, 2008

- SAES-J-903 – Intrinsically Safe System, 31 January, 2005.

- NFPA 70 – National Electrical Code 2008

- SAES-B-068 – Electrical Area Classification, 31 May, 2003.

- SAEP-16 – Project Execution Guide for Process Automation Systems, 20 November 2007

1. Attachment 1: Certification Agencies for Equipment in Hazardous Areas