This article is to guide the responsible persons (Electrical Engineer) in conducting Line & Cable Differential Protection Relay (87L/87C) Commissioning Test.

Commissioning and testing a Line & Cable Differential Protection Relay (87L/87C) is a critical step in ensuring the reliable and effective protection of transmission and distribution lines. This process involves setting up the relay, verifying its settings, and testing its functionality to ensure it operates correctly in the event of a fault. Below is a detailed guide on how to commission a Line & Cable Differential Protection Relay

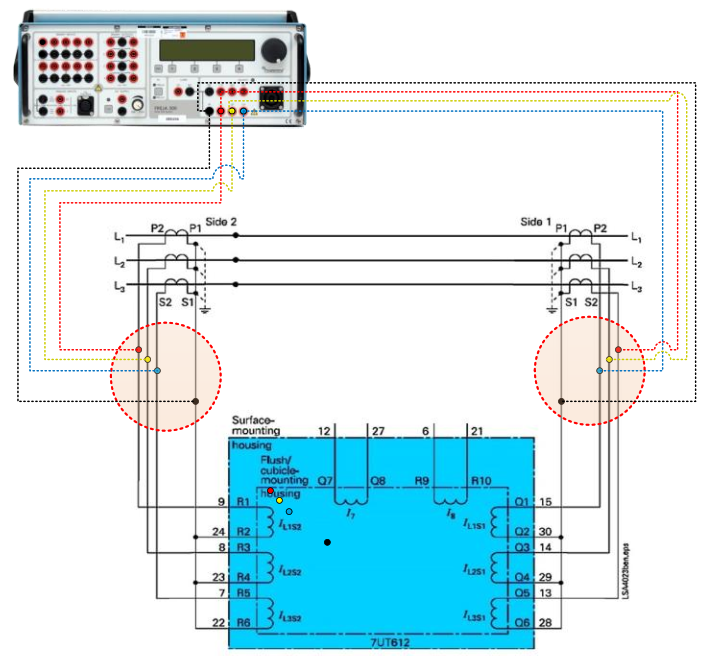

Test Equipment: Secondary Injection Test Kits, Multimeter.

SAFETY PRECAUTIONS – The following Safety precautions shall be taken in consideration prior, during and after conducting the test measurements.

- Safety tagging shall be implemented.

- Isolate the Area by Safety Warning Tape.

- Keep a Safe Distance from the device being tested.

- Wear Appropriate Personal Protective Equipment(PPE) Prior to starting any testing activity.

- Implementation of Proper Grounding.

Line & Cable Differential Protection Relay Test Procedure.

- Perform General Visual Inspection.

- The relay setting and configuration to be check as per approved final setting and approved drawings.

- Check Measurements:

- (Secondary & primary values of V and I for all phases.)

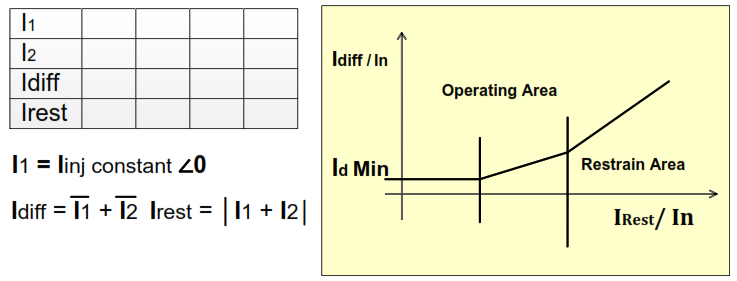

- Pickup / Drop-off Differential Current & Harmonics.

Repeat Test for yellow & blue phases.

5. Operating time test for Differential Current to be test.

5.1 Measure and Record the relay’s Pick up Differential Current and contact timing for L1 to L2 (Phase R), L2 to L3 (Phase Y), L3 to L1(Phase B), by gradually increasing the injected current until such time the pick-up Differential current is reached. Repeat step for different curves (NI, EI, LTI, DT,..etc) as per requirement or as indicated in the Test form.

5.2 Measure and Record the relay’s Drop off Differential Current and contact timing for L1 to L2 (Phase R), L2 to L3 (Phase Y), L3 to L1 (Phase B), by gradually decreasing the injected current until such time the drop-off Differential current is reached. Repeat step for different curves (NI, EI, LTI, DT,..etc) as per requirement or as indicated in the Test form.

5.3 Calculate the Reset Ratio with the formula:

Reset Ratio = (Idrop-off/Ipick-up)x100%

- Check that the differential element blocking with communication failure.

- All B/I and B/O /LED configuration to be checked as per approved scheme.

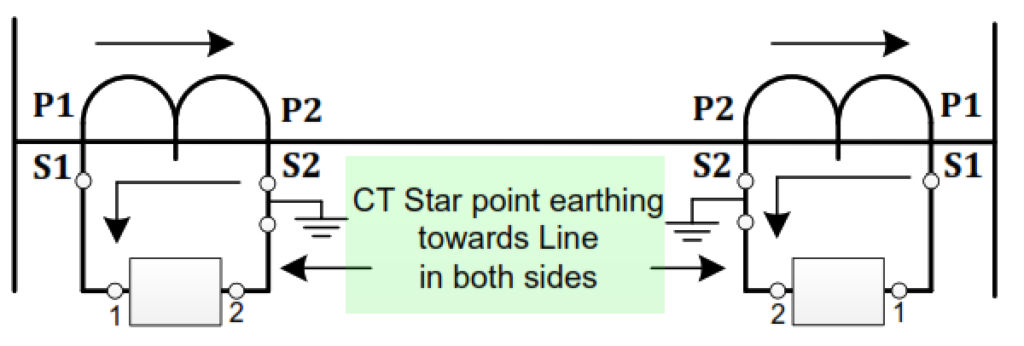

- Ideal Case for Directionality verification during Relay Final Setting test for line differential Equipment.

After checking CT polarity and all current circuit are OK.

- If applicable, Also Perform the Capacitive charging current test with the following procedures:

9.1 Activate the VTS and set value for line susceptance.

9.2 Applied voltage at the local relay without current and read from the relays the differential current and base current.

9.3 Repeat the above steps with change the values of the voltage and susceptance.

- If applicable, Also Perform Current transformer supervision test with the following procedures:

- Simulate CTs state at local relay by inject –ve sequence current.

- Increase currents gradually till reach the setting.

- Check the block state of the relay and measure the block time.

- Check the restrain state of the relay.

- Check the alarms appear at the relay at local & remote ends.

- Check the value of the relay operates (Is1CTS).

- Simulate CTS, then decrease currents gradually till the relay reset CTS state.

- Check the value of relay operates.

- Repeat the above steps for remote end.

- Insert test plug to block the relay in order to prevent wrong operation.

- Check inter-trip scheme by Closing local CB then send inter-trip, remote CB will trip. During this, measure send voltage in local substation and measure receive voltage in remote substation and repeat for remote substation.

- Check operating time (loop time).