Marine engines, also known as ship engines or boat engines, are the powerhouses of maritime vessels, providing propulsion for ships, boats, and other watercraft. These engines are designed to operate in the demanding marine environment and come in various types, each with its own characteristics and applications.

Internal Combustion Engines:

1. Diesel Engines:

Diesel engines are the most common type of marine propulsion engines. They operate on diesel fuel and are known for their fuel efficiency, reliability, and durability. Diesel engines are widely used in commercial ships, including cargo vessels, tankers, and passenger ferries.

The diesel engine belongs to the category of internal combustion engines, where fuel is ignited by injecting it into hot, high-pressure air within a combustion chamber. This process is known as the Diesel cycle. In diesel engines, fuel is directly injected into the combustion chamber and ignited by the high temperatures resulting from compressing the air before fuel injection.

The power produced by a diesel engine depends on the torque it can generate at a specific rotational speed (angular velocity). This relationship is expressed by the formula:

P=T×ω=T 2π (rpm/60)

Where:

- ( P ) is the power output

- ( T ) is the torque

- ( \omega ) is the rotational speed (angular velocity) in revolutions per minute (rpm)

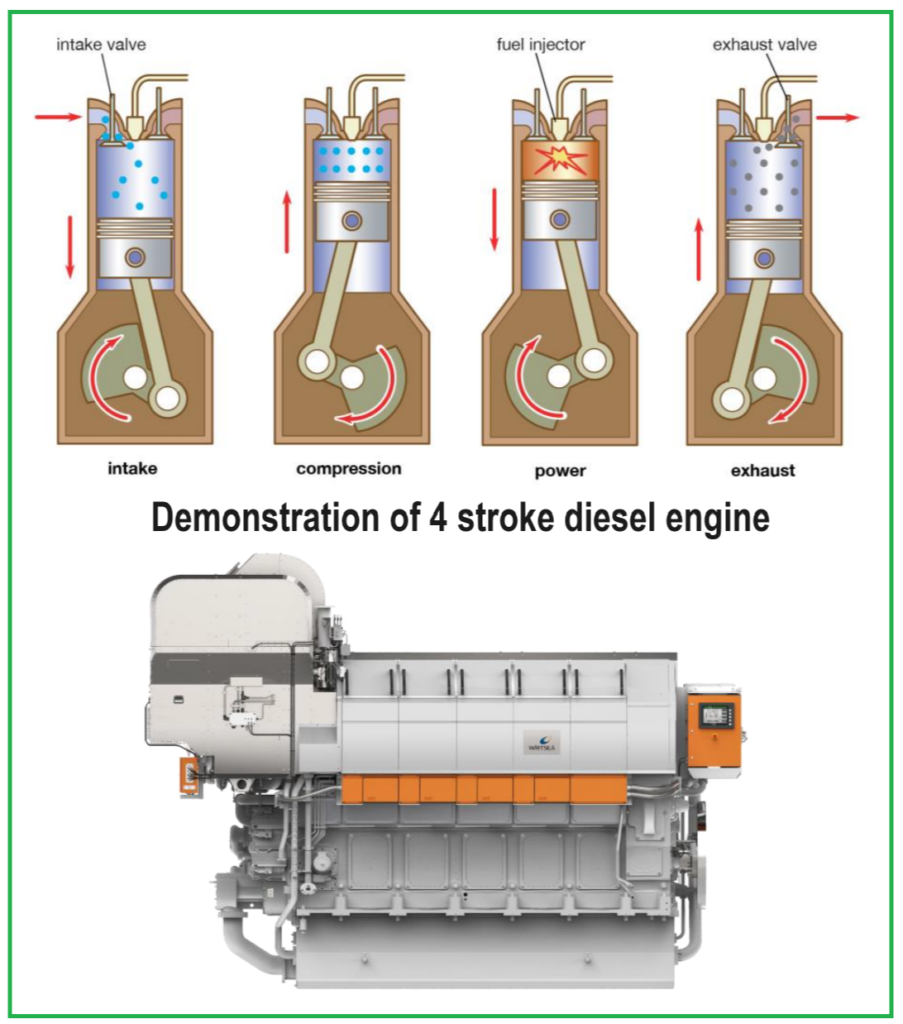

Similar to other internal combustion engines, diesel engines follow a fixed sequence of events, which can occur in either four strokes or two. A stroke refers to the movement of the piston between its extreme positions, and each stroke is completed within half a revolution of the crankshaft.

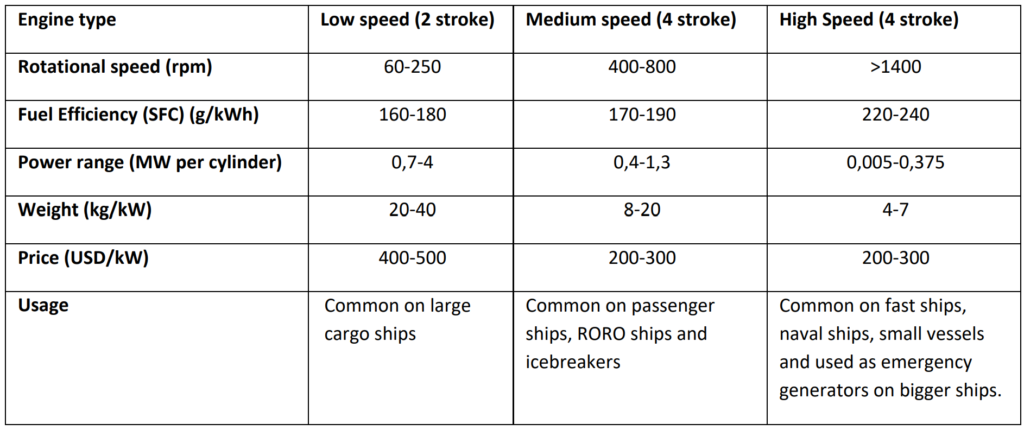

Diesel engines can be classified based on their rotational speed and operating principle. Rotational speed classifications include low-speed engines (less than 400 rpm), medium-speed engines (400-1200 rpm), and high-speed engines (over 1400 rpm). They can also be categorized based on their operating principle, such as two-stroke or four-stroke engines. For a comprehensive comparison of different types of diesel engines, refer to Table 8-1.

Comparison of diesel engine types

Gasoline Engines: Gasoline engines, also known as petrol engines, run on gasoline fuel. They are commonly found in smaller vessels such as pleasure boats, yachts, and personal watercraft due to their lightweight and high power output.

2. Gas Turbine Engines:

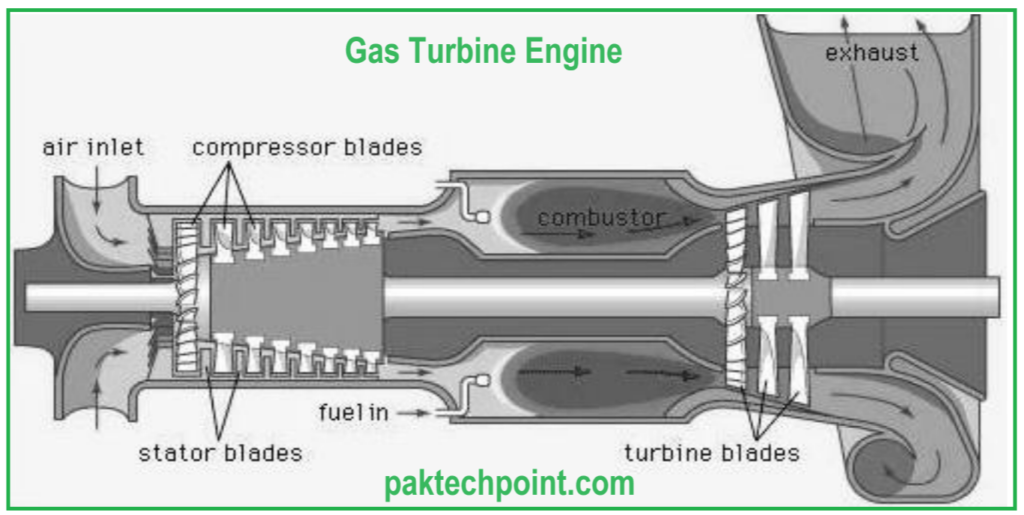

Gas turbine engines use hot gases to drive a turbine, which in turn drives the ship’s propeller. Gas turbines are known for their high power-to-weight ratio and are often used in high-speed naval vessels, fast ferries, and some commercial ships.

Gas turbines operate by compressing air to a high pressure and then adding fuel into the compressed air, which undergoes combustion to produce energy. This energy is used to rotate a shaft that drives the compressor. The excess energy generated is utilized to produce thrust or work through an independent turbine, which helps to rotate the ship’s propeller. Gas turbines are known for their relatively low fuel efficiency, typically in the range of 220-260 grams per kilowatt-hour (g/kWh) depending on operating conditions. They require high-quality Marine Gas Oil for operation.

Despite their low fuel efficiency, gas turbines offer several advantages. They have a low weight-to-power ratio, typically ranging from 0.8 to 1.2 kilograms per kilowatt (kg/kW), and can generate power in the range of 10 to 30 megawatts per unit. Gas turbines are compact, lightweight, and generally experience fewer breakdowns compared to other engine types. They are also environmentally friendly in terms of emissions. However, their high fuel consumption raises questions about their economic feasibility.

Transferring the power generated by the main engine to the propeller requires a transmission system. There are various methods for this, including mechanical, electric, and hydraulic systems. In mechanical transmission systems, power is directly transmitted to the propeller shaft or through a gearbox, which adjusts the speed of the propeller without affecting the engine speed. Electric transmission systems involve the engine driving a generator, with the generated electricity then powering a motor connected to the propellers. This method is common in passenger and cruise ships where varying speeds and demands for electricity are present. Hydraulic transmission systems, similar to mechanical systems, use a hydraulic pump to deliver high-pressure fluid to a control valve, which regulates the volume and direction of fluid flow to drive a hydraulic motor connected to the propeller. This system is particularly suitable for applications requiring high torque, such as icebreakers, and for ships with high electrical energy demands.

3D Demonstration of Gas Turbine

3. Steam Engines:

Steam turbines use steam generated by heating water to drive a turbine. While steam engines were once widely used in ships, they have largely been replaced by more efficient diesel and gas turbine engines. However, steam turbines are still used in some specialized vessels and for certain propulsion systems.

Steam turbines have historically been a popular choice for large marine propulsion systems due to several advantages. These include minimal vibration, low weight, compact size requirements, and relatively low maintenance costs. Steam turbines can be designed to provide power ratings suitable for various marine propulsion needs.

In a steam turbine system, mechanical work is generated by utilizing the energy stored in steam. The process begins with high-pressure steam, typically around 60 bar at 510°C, generated in a boiler. This high-pressure steam is then expanded through nozzles to create a high-velocity steam jet. The nozzles convert the heat energy in the steam into kinetic energy. The high-velocity steam jet is directed onto blades mounted on the periphery of a wheel or disc, as shown in Figure 8-5. The shaping of these blades causes a change in the direction and velocity of the steam jet. It’s important to note that the steam itself does not directly push the wheel; instead, it imparts its energy to the blades, causing them to rotate.

Steam turbines can operate using various types of fuel, including diesel, liquefied natural gas (LNG), or even nuclear power. However, they are generally characterized by relatively low fuel efficiency, typically in the range of 230g/kW to 290g/kW, depending on factors such as circulation and engine power. Despite their efficiency drawbacks, steam turbines are known for their simplicity and reliability. However, they tend to be bulky and heavy due to the additional equipment required for their operation.