Main keywords for this article are NEC IEC Based Low Voltage Cables Selection Criteria, IEC Low Voltage Cable, Low Voltage Cable Ampacity, Low Voltage Cable Testing and Inspection.

Low Voltage Cables Selection References

American Society for Testing and Materials (ASTM)

B 3 Specification for Soft or Annealed Copper Wire B 8 Specification for Concentric-Lay-Stranded Copper Conductors, Hard, Medium-Hard, or Soft

Institute of Electrical and Electronic Engineers (IEEE)

383 Type Test of Class 1E Electric Cables

1202 Flame Testing of Cables for Use In Cable Trays

Insulated Cable Engineers Association / National Electric Manufacturers Association (ICEA/NEMA)

ICEA S-95-658/NEMA WC-70 Power Cables Rated 2000 Volts Or Less For The Distribution Of Electrical Energy

International Electrotechnical Commission (IEC)

60038 IEC Standard Voltages

60228 Conductors of Insulated Cables

60332-3 (series)Tests on Electric and optical fibre Cables under Fire Conditions: Test for vertical flame spread of vertically-mounted bunched wires or cables.

60502 Extruded Solid Dielectric Insulated Power Cables for Rated Voltages from 1 kV up to 30 kV.

IEC 60227 : Polyvinyl chloride insulated cables of rated voltages up to and including 450/750 V

National Fire Protection Association (NFPA)

70 National Electrical Code (NEC),

Underwriters Laboratories, Inc. (UL)

44 Rubber-Insulated Wires and Cable

1569 Metal Clad Cables

NEC IEC Based Low Voltage Cables Selection Criteria

This article is about the general requirements for low voltage power cables.

- Low voltage power cable shall be manufactured and tested in accordance with IEC 60502 or ICEA S-95-658/NEMA WC-70.

- Cable manufactured to IEC 60502 shall conform to section 5.

- Cable manufactured to ICEA S-95-658/NEMA WC-70shall conform to section 6.

IEC Low Voltage Cable

- Cable shall be manufactured and tested in accordance with IEC 60038, 60228, 603323, 60502.

- The conductors shall be plain annealed circular stranded copper conforming to IEC 60228 Class 2.

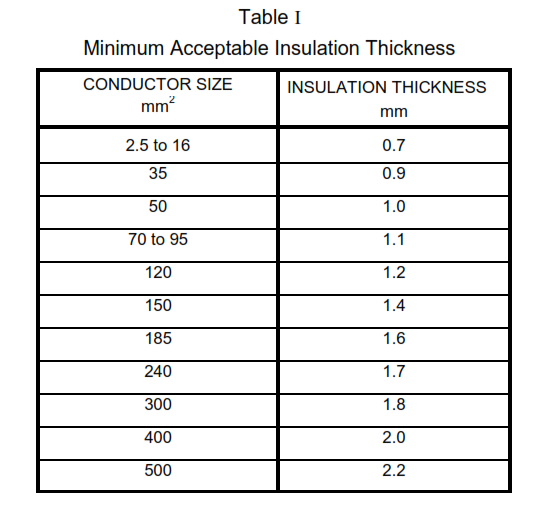

- Low voltage single conductor cables shall be insulated with cross-linked polyethylene (XLPE) insulation extruded directly over the copper conductors or ethylene propylene rubber (EPR). The cable construction shall be in accordance with IEC 60502. Table I lists the minimum acceptable insulation thickness of the cables.

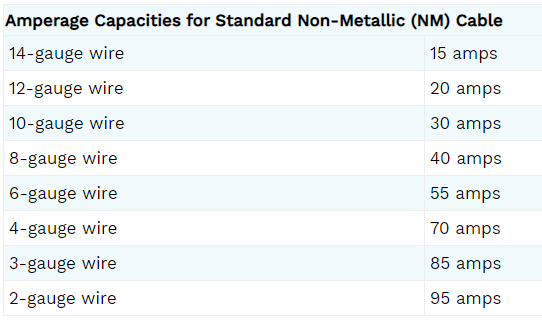

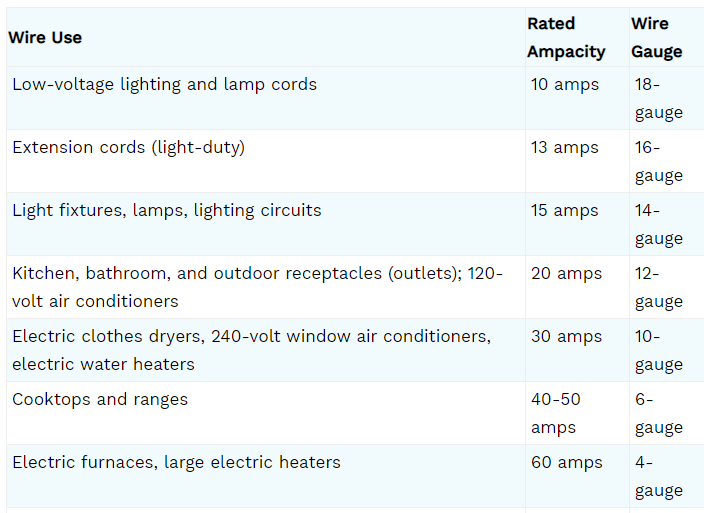

Matching Wire Size to Circuit Amperage

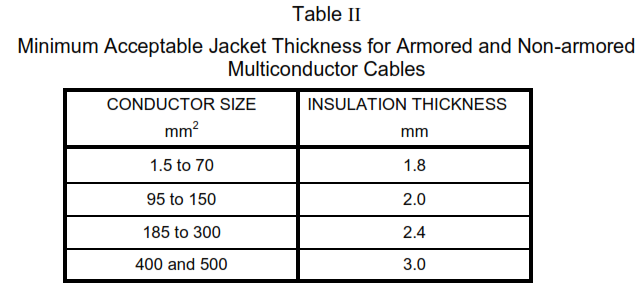

- Multiconductor cables shall have a flame retardant and termite resistant PVC jacket. The material for the cable jacket shall be extruded directly onto the surface to be covered. Table II lists the minimum acceptable jacket thickness for armored and nonarmored multiconductor cables. The cable jacket shall be continuous, homogeneous, voidless, seamless, and free of foreign material.

- Cable shall conform to flame retardance test in accordance with IEC 60332-3.

ICEA Low Voltage Cable

- Cable shall be manufactured and tested in accordance with all applicable American standards listed in section 2, with the additional requirements of this section.

- Conductor material shall be plain annealed copper in accordance with ASTM B 3. Conductors shall be concentric lay Class B stranded in accordance with ASTM B 8.

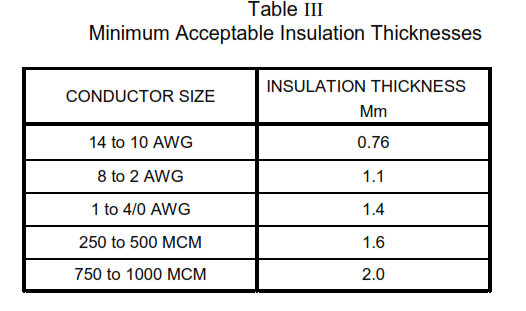

- Low voltage single conductor cable shall be insulated with cross-linked polyethylene (XLPE) insulation extruded directly over the copper conductors or ethylene propylene rubber (EPR). Table III lists the minimum acceptable insulation thickness of the cables. The cable construction shall be in accordance with UL 44.

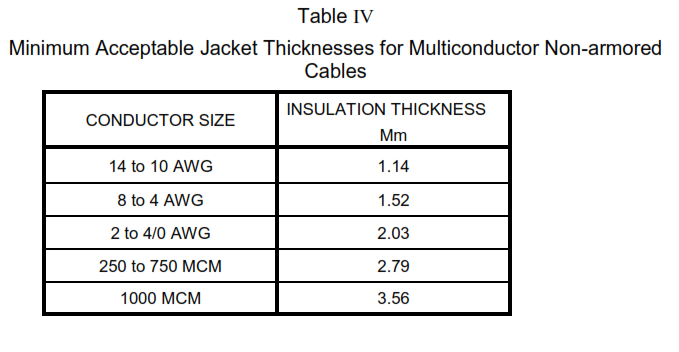

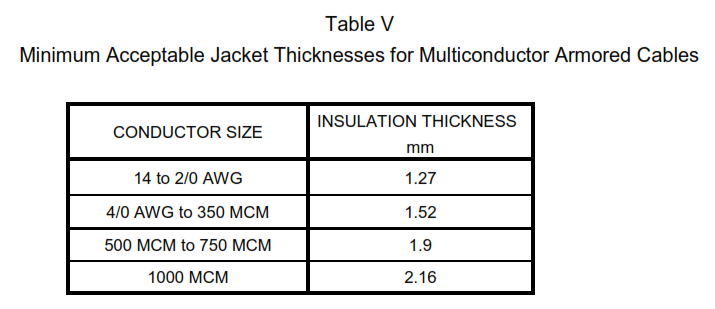

- Multiconductor cables shall have an overall PVC jacket consisting of an extruded layer of black PVC suitable for the operating temperature of the cable. Tables IV and V list the minimum acceptable jacket thickness. The cable jacket shall be continuous, homogeneous, voidless, seamless, and free of foreign material. The PVC jacket shall be flame retardant and termite resistant.

Number and Size of Cables

Low Voltage Cable Power Cables

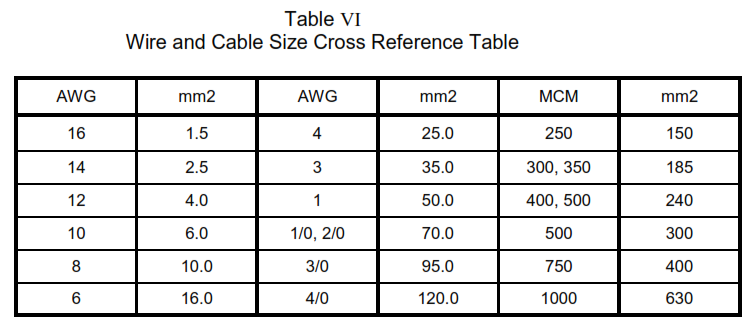

Insulated conductors shall be supplied in the following standard sizes: 12, 10, 8, 6, 4, 2, 1/0, 2/0, and 4/0 AWG; 250, 350, 500 and 750 MCM or the standard metric equivalent. Multiconductor power cable shall contain 2 or more power circuit conductors plus ground wire(s) and may also contain insulated control wires in sizes 14 or 12 AWG. Table VI defines the acceptable US to Metric cross reference.

Control Cables

Conductors shall be 14, 12 or 10 AWG or the standard metric equivalent. The number of conductors should in general be 5, 12, 19 or 37.

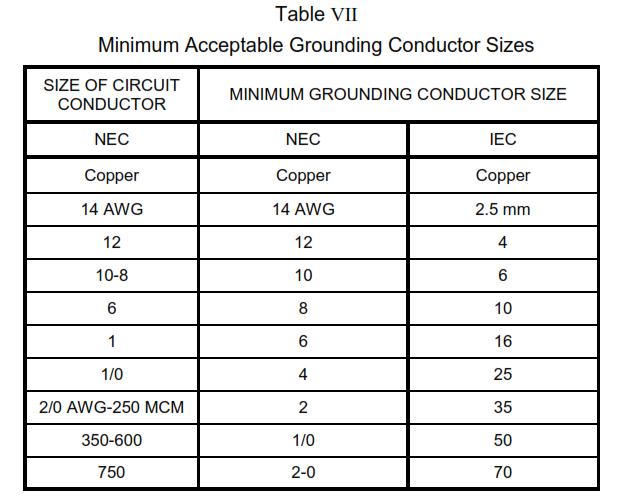

Ground Conductors

Ground conductors shall conform to NFPA 70. See Table VII for minimum acceptable grounding conductor sizes.

Low Voltage Cable Ampacity

The base current carrying capacity of cables shall be in accordance with NFPA 70, Tables 310-16 to 310-20.

Single Conductor Cables – Building wires

- Insulated conductor of single conductor cable shall have PVC jacket unless otherwise specified in below data sheet.

9.2 THHN / THWN type single core wire installed in conduit for wiring of lighting fixture circuits,

receptacles and building services equipment shall comply with requirements of NEC – Article 310,

UL Standards 83 and 1063

9.3 PVC type single core building wire shall be compliant with IEC 60227-1

Multiconductor Cables

Non-armored Cables

- Insulated conductors of the multiconductor cable shall be assembled with grounding conductors and non-hygroscopic filler material in the interstices. Assembly shall be bound with a binder tape or other suitable material, where necessary. PVC outer jacket shall be extruded over the bound assembly.

- Armored cable shall conform to UL 1569. Armor material may be galvanized steel or aluminum. Armor may be interlocking metal tapes; a continuous

corrugated sheath; or a single layer of round wires. - Insulated conductors shall be assembled with grounding conductors and nonhygroscopic filler material in the interstices. The assembly shall be bound with a binder tape or other suitable material, where necessary. An extruded layer of flame retardant PVC compound shall be applied over the core assembly to form a circular cable and to serve as bedding for the armor. The armor shall then be applied using additional bedding material if required. If a layer of round wire armor is used, a galvanized steel tape may be applied over the wire armor as binder in open helix.

- Cables shall have an overall PVC jacket applied over the armor, consisting of an extruded layer of black PVC suitable for the operating temperature of the

cable. PVC jacket shall be flame retardant and termite resistant.

Low Voltage Cable Testing and Inspection

The following routine tests shall be performed:

a. DC conductor resistance test

b. Insulation resistance test

c. High voltage test (Hi Pot)

Low Voltage Cable Identification and Tagging

- The individual wires in multiconductor control cables shall be color coded in accordance with ICEA S-95-658/NEMA WC-70,

- Power cable shall have the following core (color) designations:

a. Single core: Black

b. 2 cores: Black, White

c. 3 cores: Yellow, Red, Blue

d. 4 cores: Black, Red, Blue, Yellow

e. Ground Conductor: Insulated Green, with insulation - Finished cable shall be identified by embossing the following identifications on cable external surface at less than 1 m intervals longitudinally:

Manufacturer’s name or trademark

Year of manufacture

Number of cores and size

Rated voltage and cable description

UL or other accredited testing laboratory label Conductor material

Size of ground conductor

Conductor temperature rating

Insulation type and thickness

Oil resistance I or oil resistance II - A weatherproof tag suitable for 2 years of outdoor storage shall be affixed to each reel, visible without removal of packing material, with the following information:

a. Name and kind of cable

b. Number of cores and size

c. Length

d. Net weight and gross weight

e. Direction of winding of cable

f. Indicator of cable end position

g. Manufacturer’s name or trademark

h. Year and month of manufacture

i. Drum number and color identification, if specified in purchase order

j. Purchase order number

k. Manufacturer’s item code number

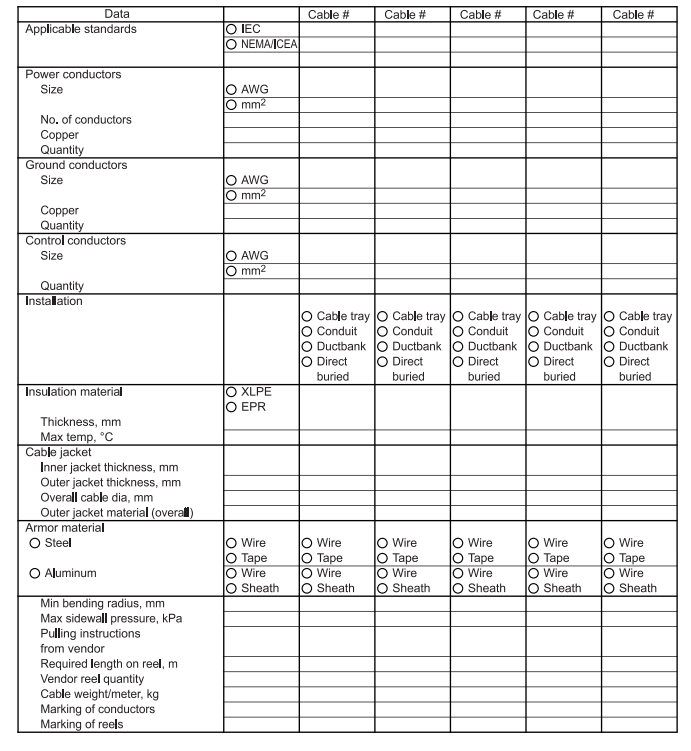

l. Manufacturer’s reel number - Data sheet of low voltage cable

Main keywords for this article are NEC IEC Based Low Voltage Cables Selection Criteria, IEC Low Voltage Cable, Low Voltage Cable Ampacity, Low Voltage Cable Testing and Inspection.