This article is about Non-Hazardous Outdoor Enclosures, Installation and Commissioning and Materials Selection & Requirements of Electrical Power System as per International Codes and standards for Commercial Buildings, Plants and Refinery Projects.

Non-Hazardous Outdoor Enclosures, Installation and Commissioning

Certification & 3rd Party Listing – General Purpose Boxes & Enclosures

- “Boxes and Enclosure Certification:

In outdoor plant areas, boxes and enclosures shall be certified by the manufacturer as:

(a) NEMA 250/NEMA ICS 6 Type 4; or

(b) NEMA Type 3 manufactured copper free cast aluminum (0.4 of 1% maximum), or plastic (including fiberglass); or

(c) IEC 60529 Type IP54 or better” - “Box and Enclosure Certification:

In outdoor plant areas, outside the perimeter of process units, and other industrial areas, boxes and enclosures shall be certified by the manufacturer as:

(a) NEMA Type 3 or 4; or

(b) IEC 60529 Type IP54 or better” - “Box and Enclosure Certification:

In outdoor plant and other industrial areas located in severe corrosive environments, boxes and enclosures shall be certified by the manufacturer as:

(a) NEMA Type 4X (except galvanized and/or painted or coated carbon steel sheet metal enclosures are not permitted); or

(b) NEMA Type 3 or 4, manufactured of copper free cast aluminum (0.4 of 1% copper maximum), or plastic (including fiberglass); or

(c) IEC 60529 Type IP 54 or better, manufactured of stainless steel (Type 304 or better), copper free cast aluminum, or plastic (including fiberglass).

Commentary Note:

In outdoor plant and other industrial areas located in severe corrosive environments, paragraph 7.3 supersedes paragraphs 7.1 and 7.2.” - “Box and Enclosure Certification:

In outdoor non-industrial areas, boxes and enclosures shall be certified by the manufacturer as:

(a) NEMA Type 3R, 3 or 4; or

(b) IEC 60529 Type IP34 or better

Certification & 3rd Party Listing & Labeling – General Boxes & Enclosures

- Suitability: Suitability of identified equipment shall be determined by one of the following:

(1) Equipment listing or labeling

(2) Evidence of equipment evaluation from a qualified testing laboratory or inspection agency concerned with product evaluation

(3) Evidence acceptable to the authority having jurisdiction such as a manufacturer’s self-evaluation or an owner’s engineering judgment.

[NFPA 70, NEC 500.8(A)] - Cathodic protection junction box enclosures shall be certified, labeled or listed by an approved and recognized testing organization to indicate full compliance with NEMA ICS 6 and NEMA 250 for NEMA Type 4, 4X, 7, 8 or 9 enclosures, as applicable.

- Marking:

All boxes shall be durably and legibly marked with the manufacturer’s name or trademark. [NFPA 70, NEC 314.44] - Marking:

Nonmetallic wireways shall be marked so that the manufacturer’s name or trademark and interior cross-sectional area in square inches shall be visible after installation. [NFPA 70, NEC 378.120]

Material Requirements

- Boxes, Enclosures and accessories shall be new and unused.

- Boxes and Enclosures and accessories shall be in accordance with the Saudi Aramco-approved project-specific design drawings, diagrams, schedules, lists, databases, and associated design documents.

- General Boxes and Enclosures and accessories shall be free of damage.

- Boxes and Enclosures and accessories shall conform to all applicable requirements, standards, and specifications prior to release to be used as part of the work.

- General Boxes and Enclosures and accessories shall be traceable from the manufacturer and supplier through delivery, storage, fabrication, erection, installation, repair, modification and use.

- Severe corrosive environments includes:

a) Outdoor offshore locations

b) Outdoor onshore locations within one kilometer from the shoreline of the Arabian Gulf, all of the Ras Tanura Refinery and Terminal, and within three kilometers from the shoreline of the Red Sea

c) Location where chlorine or other corrosive chemicals are being handled (e.g., waste water treatment, water treatment, R.O. facilities)

d) Battery Rooms ”

Locations where chemicals are being handled, enclosures, conduit, fittings and wiring must be resistant to the chemicals present. - Types of Electrical enclosure rated not more than 1000 Volts:

a. Non-hazardous locations

1. Enclosures for indoor locations, Types 1, 2, 5, 12, 12K, and 13; and

2. Enclosures for indoor or outdoor locations, Types 3, 3X, 3R, 3RX, 3S, 3SX, 4, 4X, 6, and 6P.

b. Hazardous locations

1. Enclosures for indoor locations, Types 7 and 9;

2. Enclosures for indoor or outdoor locations, Type 8; and

3. Enclosures for mining applications, Type 10

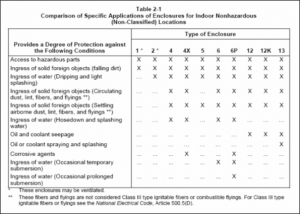

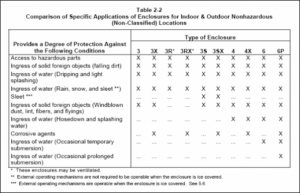

Table 2-1 and 2-2 (Attachment 1) are guides for comparing specific applications of enclosures. [NEMA 250 Sec. 1.1] - The IP Code & Designations:

A coding system to indicate the degrees of protection provided by an enclosure against access to hazardous parts, ingress of solid foreign objects, ingress of water and to give additional information in connection with such protection. Designations of the degree of protection provided by an enclosure is indicated by the IP Code arranged (See attachment 2 & 3) [IEC 60529 Sec. 3.4 and 4] - Drainage Openings:

Type 2, 3R, and 3RX enclosures shall have provisions for drainage. Drainage openings shall not be less than 3.2 mm in diameter (1/8 inch in diameter) or more than 6.4 mm in diameter (1/4 inch in diameter) unless baffled or provided with a drainage fitting.

For Type 2, 3R, and 3RX enclosures that also meet the requirements of other enclosure types, the drainage openings shall be closed by a removable plug. The enclosure shall meet the requirements of the other enclosure types with the plug installed. [NEMA 250 Sec. 3.6.3] - Gaskets: A gasket shall be secured with adhesive or by mechanical means. The gasket and its securing means shall not be damaged when the gasketed joint is opened. [NEMA 250 Sec. 3.14]

- An enclosure shall completely enclose all live parts that may be housed in it. [UL 50 Sec. 6.1.1 and NEMA 250 Sec. 1.2]

- An edge on an enclosure shall not be sufficiently sharp to constitute a risk of injury in normal maintenance or use. [UL 50 Sec. 6.1.4]

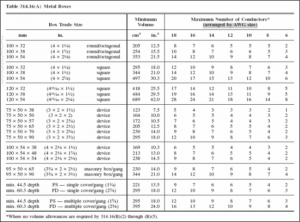

- Verify that all junction boxes, pull boxes, and conduit bodies are correct (size/ type) in according to NEC 314.16 and table 314.6(A) (Attachment 4). [NFPA 70, NEC 314.16]

Installation and Commissioning

- “Outdoor electrical equipment shall be installed in suitable enclosures and shall be protected from accidental contact by unauthorized personnel, or by vehicular traffic, or by accidental spillage or leakage from piping systems. [NFPA 70, NEC 110.26(F)(2)]

- Marking:

Service equipment rated at 600 volts or less shall be marked to identify it as being suitable for use as service equipment. Individual meter socket enclosures shall not be considered service equipment. [NFPA 70, NEC 230.66] - Only the following equipment shall be permitted to be connected to the supply side of the service disconnecting means:

(1) Meters and meter sockets nominally rated not in excess of 600 volts, provided all metal housings and service enclosures are grounded

(2) Meter disconnect switches nominally rated not in excess of 600 volts that have a short-circuit current rating equal to or greater than the available short-circuit current, provided all metal housings and service enclosures are grounded [NFPA 70, NEC 230.82] - Connection of Grounding and Bonding Equipment:

Grounding conductors and bonding jumpers shall be connected by one of the following means:

(1) Listed pressure connectors

(2) Terminal bars

(3) Pressure connectors listed as grounding and bonding equipment

(4) Exothermic welding process

(5) Machine screw-type fasteners that engage not less than two threads or are secured with a nut

(6) Thread-forming machine screws that engage not less than two threads in the enclosure

(7) Connections that are part of a listed assembly

(8) Other listed means

[NFPA 70, NEC 250.8(A)]” - Connection of Grounding and Bonding Equipment:

- Connection devices or fittings that depend solely on solder shall not be used. [NFPA 70, NEC 250.8(A)]

- For services that are dual fed (double ended) in a common enclosure or grouped together in separate enclosures and employing a secondary tie, a single grounding electrode conductor connection to the tie point of the grounded conductor(s) from each power source shall be permitted.

[NFPA 70, NEC 250.24(3)]” - A grounding electrode conductor shall be used to connect the equipment grounding conductors, the service-equipment enclosures, and, where the system is grounded, the grounded service conductor to the rounding electrode(s). [NFPA 70, NEC 250.24(D)]

- Where the enclosure or raceway is subject to physical damage, the conductors shall be installed in rigid metal conduit, intermediate metal

conduit, Schedule 80 PVC conduit, or equivalent. [NFPA 70, NEC 300.5 (D)(4)] - Where raceways contain 4 AWG or larger insulated circuit conductors and these conductors enter a cabinet, box, enclosure, or raceway, the conductors shall be protected by a substantial fitting providing a smoothly rounded insulating surface. [NFPA 70, NEC 300.4 (G)]

- Boxes shall be installed so that the wiring contained in them can be rendered accessible without removing any part of the building or, in underground circuits, without excavating sidewalks, paving, earth, or other substance that is to be used to establish the finished grade.

[NFPA 70, NEC 314.29] “ - In damp or wet locations, boxes shall be placed or equipped so as to prevent moisture from entering or accumulating within the box, conduit body, or fitting. Boxes, conduit bodies, and fittings installed in wet locations shall be listed for use in wet locations.

[NFPA 70, NEC 314.15]” - PVC conduit entering switchgear, control cabinets and similar enclosures shall be cut flush with finished grade level and shall have its inner edge filed to a smooth radius.

- Metal enclosures for grounding electrode conductors shall be electrically continuous from the point of attachment to cabinets or equipment to the grounding electrode and shall be securely fastened to the ground clamp or fitting. [NEC 250.64(E)]

- Metal enclosures that are not physically continuous from cabinets or equipment to the grounding electrode shall be made electrically continuous by bonding each end to the grounding electrode conductor. [NEC 250.64(E)]

- Separation of Junction Box from Motor:

The junction box shall be permitted to be separated from the motor by not more than 1.8 m (6 ft), provided the leads to the motor are stranded conductors within Type AC cable or armored cord or are stranded leads enclosed in liquidtight flexible metal conduit. [NEC 430.245(B)]” - Grounding Provisions:

A means shall be provided in each metal box for the connection of an equipment grounding conductor. The means shall be permitted to be a tapped hole or equivalent. [NFPA 70, NEC 314.40(D)]” - Bushings:

Covers of outlet boxes and conduit bodies having holes through which flexible cord pendants may pass shall be provided with approved bushings or shall have smooth, well-rounded surfaces on which the cord may bear. [NFPA 70, NEC 314.42]” - Surface Mounting:

An enclosure mounted on a building or other surface shall be rigidly and securely fastened in place. If the surface does not provide rigid and secure support, additional support in accordance with other provisions

of this section shall be provided. [NFPA 70, NEC 314.23(A)] - Structural Mounting:

An enclosure supported from a structural member of a building or from grade shall be rigidly supported either directly or by using a metal, polymeric, or wood brace. [NFPA 70, NEC 314.23(B)]” - Enclosures in Concrete or Masonry:

An enclosure supported by embedment shall be identified as suitably protected from corrosion and securely embedded in concrete or

masonry. [NFPA 70, NEC 314.23(G)]” - Bends:

A run of Type IGS cable between pull boxes or terminations shall not contain more than the equivalent of four quarter bends (360 degrees total), including those bends located immediately at the pull box or terminations. [NFPA 70, NEC 326.26]” - Unused Openings:

Verify that all unused openings in boxes shall be closed to afford protection substantially equivalent to the wall of the equipment. [NFPA 70, NEC 110.12(A)]” - For wire bending inside junction boxes Table 312.6(B) (Attachment 5) shall be applied where the conductor does enter or leave the enclosure through the wall opposite its terminal. [NFPA 70, NEC 312.6(B)(2)]

- Protection from Physical Damage:

Overcurrent devices shall be protected from physical damage by one of the following:

(1) Installation in enclosures, cabinets, cutout boxes, or equipment assemblies

(2) Mounting on open-type switchboards, panelboards, or control boards that are in rooms or enclosures. [NFPA 70, NEC 240.30(A)] - Vertical Position:

Enclosures for overcurrent devices shall be mounted in a vertical position unless that is shown to be impracticable

[NFPA 70, NEC 240.33] - Horizontal Position:

Circuit breaker enclosures shall be permitted to be installed horizontally when the circuit breaker clearly indicate whether they are in the open “off” or closed “on” position. [NFPA 70, NEC 240.33]” - Unused Openings:

Where metallic plugs or plates are used with nonmetallic enclosures, they shall be recessed at least 6 mm (1⁄4 in.) from the outer surface of the enclosure. [NFPA 70, NEC 110.12(A)]” - Sufficient access and working space shall be provided and maintained

about all electrical equipment to permit ready and safe operation and maintenance of such equipment. [NFPA 70, NEC 110.26]”

Outdoor offshore locations and Outdoor onshore locations within one kilometer from the shoreline of the Arabian Gulf, all of the Ras Tanura Refinery and Terminal, and within three kilometers from the shoreline of the Red Sea are considered as severe corrosive locations.

Locations where chemicals are being handled, enclosures, conduits, fittings, and wirings must be resistant to the chemicals present. - Corrosion Resistant:

Metal boxes shall be corrosion resistant or shall be well-galvanized,

enameled, or otherwise properly coated inside and out to prevent corrosion. [NFPA 70, NEC 314.40(A)]” - Structural Mounting:

Metal braces of Junction Boxes shall be protected against corrosion and formed from metal that is not less than 0.51 mm (0.020 in.) thick uncoated. [NFPA 70, NEC 314.23(B)(2)]” - Enclosures in Concrete or Masonry:

An enclosure supported by embedment shall be identified as suitably protected from corrosion and securely embedded in concrete or

masonry. [NFPA 70, NEC 314.23(G)] “ - In outdoor plant and other industrial areas located in severe corrosive environments, equipment and terminal enclosures shall be NEMA Type 4X (except galvanized and/or painted or coated carbon steel sheet metal enclosures are not permitted).

- In outdoor plant and other industrial areas located in severe corrosive environments, equipment and terminal enclosures shall be NEMA Type 3 or 4, manufactured of copper free cast aluminum (0.4 of 1% copper maximum), or plastic (including fiberglass).

- In outdoor plant and other industrial areas located in severe corrosive environments, equipment and terminal enclosures shall be IEC 60529 Type IP 54 or better, manufactured of stainless steel (Type 304 or better), copper free cast aluminum, or plastic (including fiberglass).

- Medium and high voltage terminations installed inside enclosures located outdoors shall be considered indoor terminations if the enclosures are rated NEMA ICS 6 Type 3 or 4, or IEC 60529 Type IP54. And shall be considered outdoor terminations if the enclosure a lesser degree of protection (e.g., NEMA Type 3R).

- In outdoor plant areas, boxes and enclosures shall be certified by the manufacturer as:

(a) NEMA 250/NEMA ICS 6 Type 4; or

(b) NEMA Type 3 manufactured copper free cast aluminum (0.4 of 1% maximum), or plastic (including fiberglass); or

(c) IEC 60529 Type IP54 or better” - In outdoor plant areas, outside the perimeter of process units, and other industrial areas, boxes and enclosures shall be certified by the manufacturer as:

(a) NEMA Type 3 or 4; or

(b) IEC 60529 Type IP54 or better” - In outdoor non-industrial areas, boxes and enclosures shall be certified by the manufacturer as:

(a) NEMA Type 3R, 3 or 4; or

(b) IEC 60529 Type IP34 or better” - Enclosures that are rated:

(a) NEMA Type 3, 4 or 4X, or

(b) IEC 60529 Type IP54, or better,

shall have Type 300 Series stainless steel hardware.

Exception: Aluminum enclosures may have aluminum or aluminum alloy hinges and operating handles.”

Enclosures and junction boxes having an internal volume exceeding 2,000 cm³ shall be provided with Type 300 Series stainless steel breather and drain fittings, or a combination breather and drain fitting. - Covers: Metal covers shall be of the same material as the box with which they are used, or they shall be lined with firmly attached insulating material that is not less than 0.79 mm (1⁄32 in.) thick, or they shall be

listed for the purpose. Metal covers shall be the same thickness

as the boxes for which they are used, or they shall be listed for the purpose. [NFPA 70, NEC 314.41]” - For installations outside the area of Enclosed Equipment Accessible to Unqualified Persons, a wall, screen, or fence shall be used to enclose

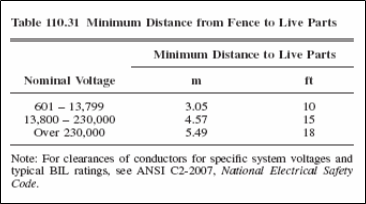

an outdoor electrical installation to deter access by persons who are not qualified. A fence shall not be less than 2.1 m (7 ft) in height or a combination of 1.8 m (6 ft) or more of fence fabric and a 300-mm (1-ft) or more extension utilizing three or more strands of barbed wire or equivalent. The distance from the fence to live parts shall be not less than given in Table 110.31 (Attachment 6).

[NFPA 70, NEC 110.31]” - Enclosed Equipment Accessible to Unqualified Persons:

Ventilating or similar openings in equipment shall be designed such that foreign objects inserted through these openings are deflected from energized parts. [NFPA 70, NEC 110.31(D)]” - Enclosed Equipment Accessible to Unqualified Persons:

Where exposed to physical damage from vehicular traffic, suitable

guards shall be provided. Nonmetallic or metal-enclosed equipment located outdoors and accessible to the general public shall be designed such that exposed nuts or bolts cannot be readily removed, permitting access to live parts. [NFPA 70, NEC 110.31(D)]” - Enclosed Equipment Accessible to Unqualified Persons:

Where nonmetallic or metal-enclosed equipment is accessible to the general public and the bottom of the enclosure is less than 2.5 m (8 ft) above the floor or grade level, the enclosure door or hinged cover shall be kept locked. [NFPA 70, NEC 110.31(D)]” - Enclosed Equipment Accessible to Unqualified Persons:

Doors and covers of enclosures used solely as pull boxes, splice boxes, or junction boxes shall be locked, bolted, or screwed on. Underground box covers that weigh over 45.4 kg (100 lb) shall be considered as meeting this requirement. [NFPA 70, NEC 110.31(D)]” - Damp and Wet Locations:

In damp or wet locations, surface-type enclosures shall be placed or equipped so as to prevent moisture or water from entering and accumulating within the cabinet or cutout box, and shall be mounted so there is at least 6-mm (1⁄4-in.) airspace between the enclosure and the wall or other supporting surface. Enclosures installed in wet locations

shall be weatherproof. [NFPA 70, NEC 312.2]” - Damp or Wet Locations:

In damp or wet locations, boxes shall be placed or equipped so as to prevent moisture from entering or accumulating within the box. Boxes installed in wet locations shall be listed for use in wet locations.

[NFPA 70, NEC 314.15]” - Unless made of a material judged suitable for the condition or unless corrosion protection approved for the condition is provided, ferrous or nonferrous metal underfloor raceways, junction boxes, and fittings shall not be installed in concrete or in areas subject to severe corrosive

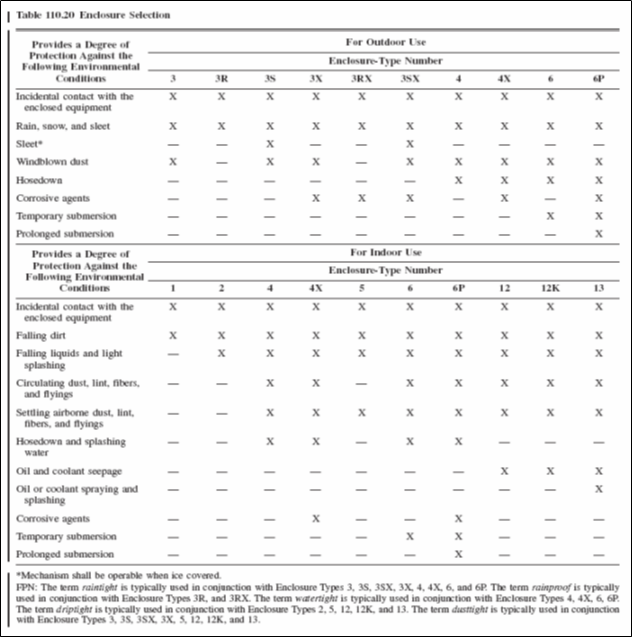

influences. [NFPA 70, NEC 390.2(B)]” - Table 110.20 (Attachment 7) shall be used as the basis for selecting industrial control panel enclosures for use in specific locations other than hazardous (classified) locations. The enclosures are not intended to protect against conditions such as condensation, icing, corrosion,

or contamination that may occur within the enclosure or enter via the conduit or unsealed openings. [NFPA 70, NEC 409.100]

International Standard and Codes for Non-Hazardous outdoor Enclosures

- Non-Hazardous Indoor Enclosures, Installation and Pre-Commissioning

- Boxes, Enclosures, and Accessories Materials Selection & Requirements

3. NFPA 70 – National Electrical Code (NEC), 2008 Edition

4. SAES-P-104 – Wiring Methods and Materials, 13 January 2008

5. SAES-P-100 – Basic Power System Design Criteria, 25 June 2007

6. ANSI/IEC 60529 – Degrees of Protection Provided by Enclosures (IP Code) (identical national adoption), 2004

7. NEMA ICS 6 – Industrial Control & Systems Enclosures – 1993 (R2006)

8. NEMA 250 – Enclosures for Electrical Equipment (1000 Volts Maximum), 2008

9. UL 50 – Enclosures for Electrical Equipment, Non-Environmental Considerations, September 2007

1. Attachment 1: Table 2-1 & Table 2-2 – Guides for Comparing Specific Applications of Enclosures – NEMA 250

2. Attachment 2: Arrangement of the IP Code – IEC 60529

3. Attachment 3: Elements of the IP Code and their Meanings – IEC 60529

4. Attachment 4: Table 314.16(A) – Metal Boxes – NFPA 70

5. Attachment 5: Table 312.6(B) – Minimum Wire-Bending Space at Terminals – NFPA 70

6. Attachment 6: Table 110.31 – Minimum Distance from Fence to Live Parts – NFPA 70

7. Attachment 7: Table 110.20 – Enclosure Selection – NFPA 70