Peripheral Hardware Installation in Vibration System Application

Watertight (NEMA 4) Proximitor/Interface Modular Housings

The most essential aspect of proper NEMA 4 housing installation is its location in relation to the various transducer signal lines coming into it. It is not the intent of this Applications Note to recommend the proper location of any housing but merely to explain “how” the housings are used and “why”.

The Bently Nevada watertight (NEMA 4) housings are designed to provide protection for Bently Nevada Proximitors and various transducer interface units in areas where they would otherwise be subjected to possible damage from moisture in the operating environment. In order for any enclosure to be NEMA 4 rated, it must pass certain tests to guarantee its watertightness.

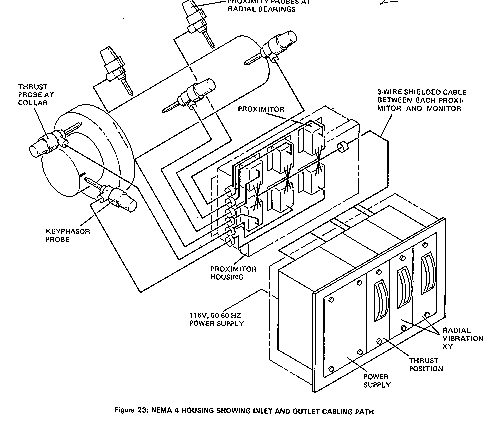

Housings are supplied with up to six (6) 3/4 inch NPT inlet fittings (depending on which housing is required) and a 1-1/4 inch NPT outlet fitting. Reducers are provided if 1/2 inch inlet or 1 inch outlet conduit is employed. Once the housing location is selected, position it in such a way that the available knockouts for inlet and outlet are most nearly coincident with the conduit lines. Then remove only those knockouts needed to cover the number of conduit lines. Removing more knockouts than necessary would void the NEMA 4 rating.

Figure 23 shows inlet and outlet paths via a NEMA 4 housing for a typical Bently Nevada machinery protection system.

Selection of Conduit Attachment Fittings

The conduit attachment fittings supplied with Bently Nevada NEMA 4 watertight housings, junction boxes and relative probe housing assemblies are 3/4 inch NPT. This conduit size easily satisfies the minimum conduit cross-to-Proximitor® extension cable as set forth in the “National Electric Code” and the “Canadian Electric Code” specification. The 1-1/4 inch NPT fitting allows adequate area for the routing of up to six (6) 3-wire shielded conductor cables to existing NEMA 4 housings.

Certain applications may require smaller size conduit for the same number of cables or more cables to be routed through 3/4 inch or 1-1/4 inch conduit sizes. To avoid selecting the wrong size conduit and conduit attachment fittings, consult the Transducer Accessory data sheet L5021.

Sealtite Flexible Conduit

Sealtite flexible conduit provides a convenient means of protecting Bently Nevada extension cables from harsh environments and mechanical damage. This type of conduit can be easily routed from the transducer to a NEMA 4 housings. The tedious layout of rigid conduit is then eliminated. In addition, the flexible type conduit lends itself to simple transducer replacement and/or recalibration. Sealtite flexible conduit is available in 1/2 inch and 3/4 inch sizes (see Transducer Accessory data sheet L5021 for ordering details and illustration).

Explosion-Proof Proximitor / Interface Module Housings

As with NEMA 4 watertight housing, proper location is essential and certain requirements are very important in the installation of explosion-proof housings.

Note: The ultimate determination of any installation in a hazardous area rests with the cognizant approving authority involved in overseeing the installation with respect to safety. Bently Nevada provided equipment must be installed in accordance with standards approved by that cognizant approving authority which makes the final decision as to whether an installation meets the specific hazardous area requirement.

Equipment located in Class I areas must comply with the following requirements:

1. They must have sufficient strength to contain an explosion.

2. Exterior surface temperature of the piece of equipment must be below the ignition temperature of the gas or vapor.

3. There must be a sufficient flame path to cool a gas should an explosion occur inside the equipment enclosure.

To ensure compliance, the following installation practices should be adhered to:

Threaded Joint Construction

For Groups C and D, there must be a minimum of five fully engaged treads; this means that for the explosion-proof Proximitor/Interface unit housings, the screw-on cover must fit tightly against the housing. Care should be given not to damage either the cover threads or the housing threads. This installation practice also applies to the explosion-proof fitting threads.

Ground Flange Construction

Mating surfaces should remain free from scratches and burrs. During the explosion-proof housing installation, care should be taken to avoid accidental scratching or the housing-to-cover mating surface. Do not use a rubber gasket to seal the housing cover to the housing.

Explosion-proof Fittings

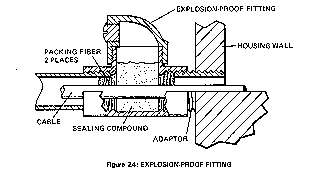

Explosion fittings provide access “to” and/or “from” explosion-proof housings, junction boxes and relative prove housing assemblies. When located in hazardous areas, proper installation procedures are essential in order to block the travel of a possible flame path down a conduit line and fro igniting the outside atmosphere.

Packing fiber should be placed around the incoming proximity probe extension cable or output signal cable, inside the fitting, followed by filling the fitting with sealing compound to not less than the internal diameter of the fitting (see Figure 24).

Note: Bently Nevada explosion-proof Proximitor®/Interface unit housings are supplied with explosion-proof fitting kits that include sealing compound, packing fiber, and appropriate size mounting adaptors.

Miniature Coaxial Connectors

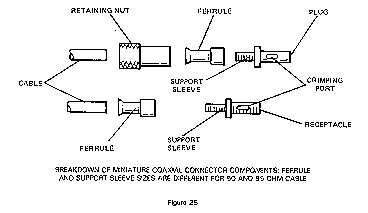

Bently Nevada utilizes miniature coaxial 50 ohm and 95 ohm connectors for all probe lead-to-extension cable and extension cable-to-Proximitor® connections. A break down of connector components is shown in Figure 25.