This article is about Power Plant Layout and Configuration and focusing to the engineers, technicians and supervisors. You will find lot of documents related to this article. Just navigate our website www.paktechpoint.com and find more articles. Please! Do not forget to subscribe our You tube channel also. Thanks in Advance.

PLEASE SUBSCRIBE OUR PAKTECHPOINT YOUTUBE CHANNEL

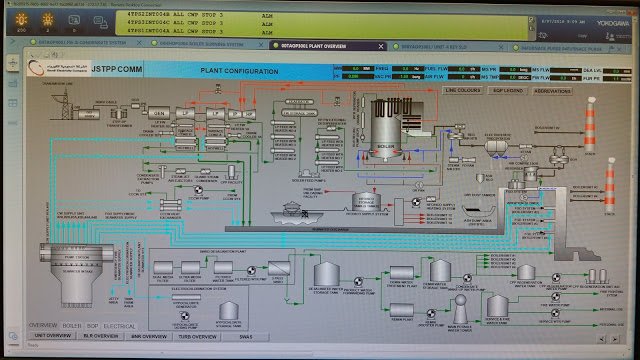

This article is about the basics functions of plant and about configuration, The below picture is from Saudi electricity plant of Saudi Arabia. You will the basic idea of Power Plant layout making and configuration with function.

Main Thermal power plant based on phenomena of converting heat energy in to electrical energy. Heat energy can be get from boiler by burning oil, HFO, HCO etc and coil. This boiler coverts the water into steam. this steam expansion in turbine created mechanical power which in turn drives big alternator couples. This is game of four energies.

Please read also: COMMISSIONING PHASE STEPS OF POWER PLANT

Chemical energy into thermal energy (Boiler) into kinetic energy (Through Turbine Torque) into electrical energy (Alternating in current stator).

Power Plant Layout and Configuration

There are main configurations and main parts.

Boiler

As everyone know used to convert water in to steam, Boiler consists of steel tubing which converts pure water in to steam. Water should be Pure. Mostly two types of boiler used. AFBC ( Atmospheric fluidized bed combustion and WHRB (waste heat recover boiler). Following is the link if you want to study more about boiler and its questions and answer also.

Please read also: Boiler-Instrumentation Related Question and Answers

Auxiliary Boiler

It consists of ID (Induced Draught) fan, FD (Forced Draught) fan and PA (Primary Air) fan.

DM Plant (Demineralized )

This is for demineralization of raw water from water source like sea or river. Because mineralized water may be harmful for boiler lines. cooling water also comes in DM Plant.

Economizer

Different economizer have different hear criteria normally having temperature of 400 to 500 c.

Because flue gases have lot of temperature, economizer just extracts the normal quantity of heat from flue gases and thus improves the efficiency of plant.

GRID SUBSTATION

It is conversion point of voltages between transmission level voltage i.e 765 kW and distribution level voltage i.e 11 kW. Substation are made up of different electric circuits and mainly with step down transformer. It is mostly located near cities to provide distribution.

Sometimes we use two different terms for GRID SUBSTATION. One is GRID and other is Substation.

Grid is made up with power sytem components generation stations, switching circuits, transmission lines, distributed load connections, distribution points. In short grid is place where two or more trnamission lines are connected to deal with power.

Second substation is part of grid. we can use it for switching and power conversion , step downing and step uping etc.

STEP UP & DOWN TRANSFORMER

To increase the voltage from one to other point, the equipment which is used is called step up transformer. Step up transformer consists of primary and secondary coils.

If the number of turns in secondary side is more than primary side is called step up transformer and vice versa for step down transformer.

GCB

GCB stands for generator circuit breaker. it has main role for switching circuit between transformer and generator. It protects from short circuits between generator and transformer thats why engineer give importanace to GCB. Its voltage rating ranging from 50 MVA to 1,400 MVA.

IPB

we have two terms which are commonly used IPB and PIB, Both are same. IPB stands for isolated-phase bus and PIB stands forPhase-isolated Bus.

GENERATOR

It is device which converts mechanical energy in to electrical. This generator based on the principle of Faraday’s law which states that when conductor move in magnetic field , electrons flow is started in one dedicated direction which is called current. This is basic definition of generator. it is also called electromagnet. Best example of generator application is dam where by water we can convert our potential and motion energy in to electrical energy.

Kinetic Energy => Electrical & Heat energy

So it is clear generator takes mechanical input and gives electrical output. This is game of moving the rotor in magnetic field stator.

EMF=B•L•V x Sine angle

FD AND ID FAN

ID fan is basically induced draft fan and it is used for removal of flue gases from from furnaces and sending to chimneys. ID fan is placed between chimney and dust collector. Basic idea about ID fan is to produce low or negative pressure for furnaces and getting flue gases with help of electrostatic recipitator.

Now come to the FD which is Forced draft fan as name indicated it provides the hot air to furnaces for combustion of fuel by producing positive pressure inside system.

ELECTROSTATIC RECIPITATOR

You can recipitator to filtration device because in the plant it removes dust or particles by ionizing the particles by electrostatic recipitator.

AIR COMPRESSOR

Air compressor compresses the air by utilizing energy. Air compressor is type of machine which converts electrical power to kinetic energy by using compressed air. After compressing air when we release air in burst manner, it will convert into kinetic energy and can be used for electrical MOVs and valve operation.

FGD SYSTEM

It is wet gas desulphurization system and used to remove sulfur dioxide gas from flue gases in plants.

WHAT IS HFO HCO STORAGE TANK

These are the storage tanks. HFO is heavy fuel tank and HCO is heavy crude oil.

WHAT IS HEATER

Heater is device to heat up water or air and any fluid material depends upon process material. Heater is simple electrical device that converts current into heat. It works on the principle of Joule’s law consists of resistor as heating element. when electrical energy passes through heating element resistor, it converts into heat energy.

PUMPS

Pump move the fluid from one place to other place by pressure. In pumps we have moving part like impeller which creates some vacuum by air pushing out the way and that space can be filled with water or air. This is basic concept of pump.

If you enjoy this article please share to your friends and comment to our article.

Hello. I have checked your paktechpoint.com and i see you’ve got some duplicate content so probably it

is the reason that you don’t rank hi in google.

But you can fix this issue fast. There is a tool that rewrites content like human, just search in google:

miftolo’s tools

The direct cost of electric energy produced by a thermal power station is the result of cost of fuel, capital cost for the plant, operator labour, maintenance, and such factors as ash handling and disposal. Indirect social or environmental costs, such as the economic value of environmental impacts, or environmental and health effects of the complete fuel cycle and plant decommissioning, are not usually assigned to generation costs for thermal stations in utility practice, but may form part of an environmental impact assessment. For units over about 200 MW capacity, redundancy of key components is provided by installing duplicates of the forced and induced draft fans, air preheaters, and fly ash collectors. On some units of about 60 MW, two boilers per unit may instead be provided. The list of coal power stations has the 200 largest power stations ranging in size from 2,000MW to 5,500MW.