Procedure of Vessel Internal Works

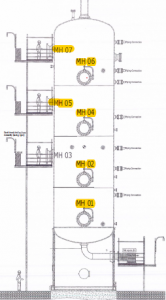

Ventilation System

Ventilation system shall be done using fans/blowers with sufficient capacity. Vacuum mode operation shall be preferred for ventilation, where required force ventilation to vessel top and allow fresh air from the bottom. Distance of the ventilation is also critical as it will obstruct access to the manhole, so careful planning shall be done prior to positioning of the fans/blowers in order to address the air circulation inside the vessel. See following photo.

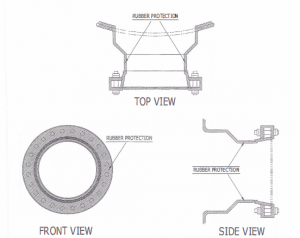

Manhole Opening, Inspection and Protection Method

All manhole opening shall be done as per construction and safety procedure. Approved safety permit shall be procured prior to nitrogen gas removal. Inspection of manhole flange serration shall also be done. After inspection of manhole flange

serration, put a rubber cover for protection. See attached following photo. Bolts, nuts and gasket shall be kept for reinstatement.

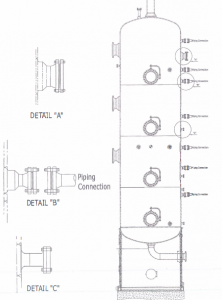

Nozzle Inspection and Protection Method

All equipment nozzles shall be inspected for its flange face serration. Should there be any unacceptable damage, it shall be corrected by re-facing it prior to vessel internal works. Appropriate cover and protection on its nozzle flanges face shall be

done. Notice shall be given to Mechanical Department should there be any piping connections to be made. Blind flanges, bolts and nuts and gaskets of correct material shall be used to cover the nozzles of equipment. Equipment nozzle shall

never be use as support by any piping connections. Gaps shall be made between two connections (equipment nozzle and pipe flanges) until final box up of the vessels and piping works are done. See attached photo.

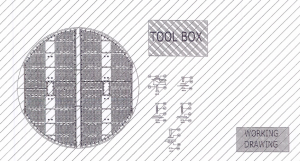

Tray Pre-assembling Working Bed

Tray pre-assembling working bed shall be of the same size as the diameter of the vessel involved. Materials to be use on top of the working bed shall be of the same materials of the vessel internal. Carefully pre-assembled the required vessel

internals (level wise) and check precisely that all components are complete and of the correct position as if you installed it inside the vessel. Check also for its cleanliness and if contaminated with rust, clean thoroughly with approved cleaning

method and solvent solution prior to installation inside the vessel. After confirmation of material and cleanliness, carefully install it piece by piece inside the vessel. See attached photo.

Scaffolding Inside and Outside the Vessel

Scaffolding inside and outside of the vessel shall be done by an approved Scaffolders only. Scaffolders shall install scaffolding with maximum effort not to damage the shell surface of the equipment most especially inside the vessel as it

will result into scratches and will lead to rust development/contamination.

All sharp corners and protruding metal ends of scaffolding shall be adequately covered with rubber. Inside scaffolding shall be installed in such a way that enough working space is provided for installation of vessel internals. Outside scaffolding shall be installed with enough platform size in front of all manholes for worker’s access during working activities. Safety for all workers inside and outside the vessels shall be given much consideration in the scaffolding erection. A temporary cabinet shall be placed (shall not obstruct manhole access) for safekeeping of personal belongings of workers inside the vessel.

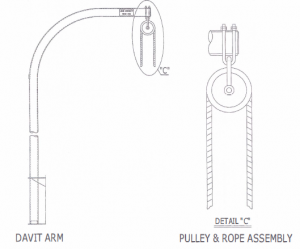

Davit Arm Load Test and Rope Pulley Installation

Davit Arm and Rope Pulley shall be installed on top of the equipment for lifting vessel internal components. Safety shall be ensured prior its installation. Workingload shall also be considered before its installation. It shall be installed in such a

way that it will not obstruct the manhole access. Rope size shall be of enough size to carry the possible load weight of the vessel internal components. See attached photo.

Mist and Dust Protection

Mist and dust contamination should be avoided during installation of vessel internals. Cover all possible entry of dust. Only authorized personnel and installer shall be allowed inside the vessel. Special clothes such as cover-all and working

shoes shall be provided to those authorized persons who will enter inside of the vessel. A special cabinet will be placed outside the vessel for safekeeping of personal belongings of personnel inside the vessel.

Material Receiving, Transportation and Control Method

Material receiving inspection and acceptance (tray floors, support angle, inlet weir, distributor and other vessel internal components) shall be done as per the approved procedure of the Saudi Aramco and International standards.

Staging, organization and cleaning of vessel internal components shall be done by the Contractor prior to issuance to sub contractor and the same shall be done by the sub contractor during site installation.

A dedicated Material Controller shall take full control in the material transportation and storage of the vessel internal components. Procedure shall be made to ensure proper storage and issuance of the vessel internal components. Latest IFC

drawings shall be made available on the material container for perusal. Should there be any discrepancy between the IFC drawings and packing list, it shall be reported immediately to the Discipline Manager for proper disposition.

Confined Space Control Method

Registration of Personnel and Personal Belonging Control A confined space entry permit shall be procured prior to start of any internal works.

Complete gas testing shall be made by competent safety personnel. A log sheet shall be made available at the entrance of the manhole for registration of all personnel who will enter the confined space work place. A dedicated trained and

competent watchman shall position in front of the manhole access and will continue to observe the activity inside the vessel at all times. All personal belongings of the workers inside the vessel shall be deposited to the temporary

cabinet located outside the entrance of the vessel equipment.

Personnel’s Outfit

All workers inside the vessel equipment shall wear cover all, full body harness (without the line yard) and shoes cover before entering the inside working area.

Lighting Method

An explosion proof with 12 volt illumination capacity lights shall be made available inside the vessel equipment during working and inspection time. Lighting shall be placed at the area most necessary for workers and inspectors.

Column Internal Surface Cleaning Method

Cleaning of internal surface of vessel equipment shall be done prior to installation of internal trays. It shall be done by wiping out dust and other foreign particles with a clean and cotton made rags. Any visible rust contamination shall be abraded with sand paper and wipe with cotton made rags or by other means of cleaning method approved by ARAMCO.

EQUIPMENT AND TOOLS FOR VESSEL INTERNEL WORKS

1. Crane for special lift

2. Slings and soft tag lines

3. Davit arm and rope pulley assembly

4. Manometer hose or its equivalent hose

5. Feeler gauges and calipers

6. Calibrated torque wrench

7. Coverall and shoe cover

8. Calibrated gas detectors

9. Fans/blowers of sufficient capacity

10. Lightings of sufficient illumination

11. Welding materials

INTERNATIONAL STANDARD REFERENCES

REIE 686 Recommended Practices for Machinery Installation and Design

ASME Sec.VIII D1 & D2 Rules for Construction of Pressure Vessels