1.0 PURPOSE

2.0 SCOPE

3.0 APPLICABLE DOCUMENTS

4.0 RESPONSI Bl LITY

5.0 MANPOWER

6.0 TOOLS & EQUIPMENT

7.0 METHODS/PROCEDURES

8.0 QUALITY CONTROL

9.0 SAFETY PRECAUTION

10. ATTACHMENTS.

RECTIFICATION PROCEDURE OF EQUIPMENT SADDLE BOLT HOLES

1.0 PURPOSE

This method statement shall provide minimum guidelines to carry out the Rectification of equipment saddle bolt holes for plants and refinery projects to ensure that the work is carried out in accordance with Project Drawings and Project Specifications.

2.0 SCOPE

This method statement will cover the Rectification of equipment saddle bolt holes at plants and refinery projects.

3.0 APPLICABLE DOCUMENTS

3.1 ARAMCO Project Specification and Standards

3.1.1 SAEP-302 Instruction for Obtaining a Waiver of a Mandatory Saudi ARAMCO Engineering Requirements.

3.1.2 SAES-M-001 Structural Design for Non-Building Structure.

3.1.3 12-SAMSS-008 Erection of Structural and Miscellaneous Steel.

3.1.4 SCHEDULE Q Saudi ARAMCO Project Quality Requirements.

3.1.5 Saudi ARAMCO Safety Requirement for Scaffolds.

3.1.6 Saudi ARAMCO Construction Safety Manual.

3.2 Industry Codes and Standards

3.2.1 AISC AISC Code of Standard Practice, Specification for Structural Joints Using ASTM A325 or A490 Bolts.

3.2.2 AISC 303-05 Code of standard practice for steel building and bridges.

3.3 Inspection and Test Plan.

3.3.1 SATIP-M-001-01 Structural Steel for Piperack, Steel Supports & Miscellaneous Steel Structures.

3.3.2 SATR-M-2002 Pre-Installation Procedure Verification Testing Using the Turn-of-Nut Method (ASTM A325 or ASTM A490 Bolts).

3.3.3 SAIC-M-2009 High Strength Bolts Tightening Inspection and Testing (ASTM A325 or A490 Bolts).

3.3.4 S-000-3130-002 Construction specification for steel structures site erection.

4.0 RESPONSIBILITY

4.1 Construction Manager is responsible for implementing HSE and shall study, analyze and schedule all construction activities with his department to include manpower and equipment line up as well as other possible resources required for the successful implementation of the construction work activities. Study all aspects of work procedure as per DEC/JGC Technical Scope of Work.

4.2 Mechanical Supervisor shall study and review all necessary documents for the rectification works in his area. He shall monitor the availability of materials in accordance with the schedules and construction analysis. He shall be directly reporting to the Construction Manager. He shall coordinate with other discipline to visualize possible conflicts in the drawings as well as in the schedules to provide other options in preventing unnecessary delays obstructions.

4.3 Mechanical Foreman shall be responsible for the direct work supervision at site and ensure that the work is performed safely. He shall monitor the activity.

4.4 QC Inspector shall be responsible in monitoring and inspection of the work and ensure that the work is performed in accordance with Technical Scope of Work and Standards.

4.5 Safety Officer/Supervisor shall be responsible in monitoring safety aspects and ensuring that the work is done in accordance with Safety Standard Procedure. He shall discuss to the field supervisor’s the characteristics of related materials and status of work area giving reminders as an additional point to work safely.

5.0 MANPOWER

5.1 Manpower will consist of the following, but not limited to as listed to as below:

• Mechanical Foreman

• Welder

• Helper/Fire watcher

• Scaff older (by others)

• Safety Officer/Supervisor

• QC Inspector

6.0 TOOLS AND EQUIPMENT

6.1 Tools and equipment needed should be in good condition and must be checked by Mechanical Supervisor / Safety Officer prior to use in the good condition area. These includes but not limited as below:

• Welding Machine

• Pencil Grinder

• Grinder

• Welding outfits

• Electric Drill

7.0 METHODS / PROCEDURES

7.1 Preparation Works

7.1.1 Secure work permit from DEC/JGC concerned personnel prior to start of work/activity.

7.1.2 Install scaffold if required (by others)

7.1.3 Prepare all materials or tools needed for the job.

7.2 Rectification Procedure

7.2.1 Remove setting bolt one at a time prior for rectification, refer to attachment B for sequence.

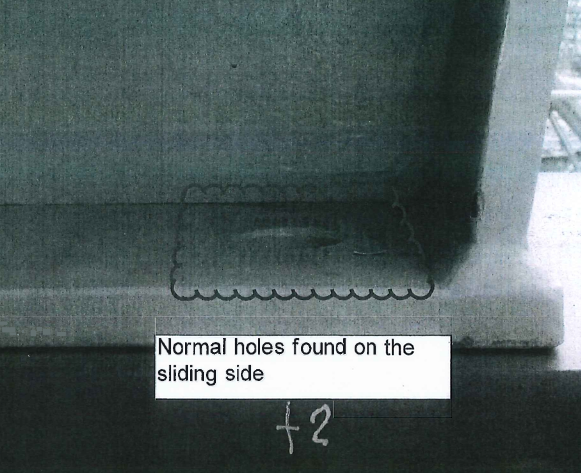

7.2.2 On sliding side of equipment saddle, enlarge the holes as per required, refer to attachment B for slotted hole detail.

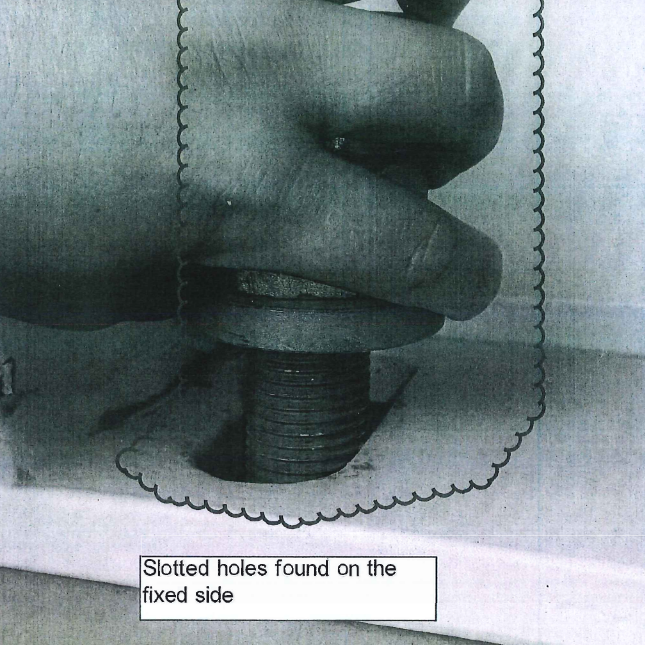

7.2.3 For fixed side of equipment saddle, fill the holes as required with weld metal as per approved WPS then flush grind surface to smoothen in

accordance with clause 10.4.1 of AISC 303-05-Code of standard practice for steel building and bridges

7.2.4 Inspect equipment saddle both fixed and sliding side to ensure all activities are being done as per the drawing details and standard.

7.2.5 For damage paint, touch-up as per S-000-13A0-001.

7.2.5.1 All repaired, damaged steel supports will be coated as per the applicable coating schedule.

7.2.5.2 Touch up application shall be done using brush/roller.

7.2.6 After acceptance re-install setting bolt and tighten as per required torque.

8.0 QUALITY CONTROL

8.1 QC Inspector will be present at site during the activity to ensure that the activity will not generate stress on the structure.

8.2 QC Inspector will produce all the documents attesting to the acceptability of the works and submits.

8.3 QC Inspector has to utilize the applicable SATIP’s & SAIC’s for every activity.

9.0 SAFETY PRECAUTION

9.1 Approved work permit should be obtained to concerned personnel prior to the start any activities.

9.2 Work execution shall be carried out in accordance with this method of statement.

9.3 The necessary manpower inclusive of supervisory staff, tools, equipment, materials, and other resources required must be made available and ready to use.

9.4 During the activity, closely supervision shall be done by field foreman.

9.5 All workers shall wear as a minimum PPE required below.

- Safety Helmet

- Safety glasses

- Safety Shoes

- Gloves

- Safety Harness (Full Body Harness)

9.6 Sufficient lightings shall be provided if work is done at night time. Work at night shall be approved by client.

9.7 Good housekeeping must be maintained in the duration of works.

9.8 Safety Officer/Supervisor shall monitor compliance of entire working crew to safety procedure until the work is fully completed.

9.9 ARCC shall make sure that all shall be incident and injury free.

9.10 The area shall blocked by physical barricade or warning tapes during activities is to be done to ensure safety.