| 1.0 | PURPOSE |

| 2.0 | SCOPE |

| 3.0 | APPLICABLE DOCUMENTS |

| 4.0 | MANPOWER |

| 5.0 | TOOLS AND EQUIPMENTS |

| 6.0 | METHOD/PROCEDURES |

| 7.0 | QUALITY CONTROL |

| 8.0 | SAFETY PRECAUTIONS |

| 9.0 | ATTACHMENT |

Repair of Warped/Distorted Slide Plate on Dummy Leg

1.0 PURPOSE

This method statement provides the specific guidelines and methodology to carry out the Repair of Warped/Distorted Slide Plate on Dummy Leg at Plants and Refinery Projects.

2.0 SCOPE

2.1 This method statement covers the general activities to be performed in the Repair of Warped/Distorted Slide Plate on Dummy Leg. The work covers the following activities:

- Material Preparation.

- Heating.

- Non Destructive Examination.

2.2 Separate procedure or method statement is required for correction of excessive warpage that exceeds ASTM A/A6M* criteria.

3.0 APPLICABLE DOCUMENTS

3.1 Saudi ARAMCO Project Specification and Standards

| 3.1.1 | SAES-W-011 | Welding Requirement for On-plot Piping |

| 3.1.2 | 12-SAMSS-007 | Fabrication of Structural and Miscellaneous Steel |

| 3.1.3 | 12-SAMSS-008 | Erection of Structural and Miscellaneous Steel |

| 3.1.4 | Schedule Q | Project Quality Requirements |

3.1.5 Saudi ARAMCO Construction Safety Manual

3.2 Codes and Standards

3.2.1 AWS D1.1 Structural Steel

3.3 Inspection and Test Plan

3.3.1 SATIP-M-001-01,Structural Steel for Pipe rack, Steel supports & Miscellaneous, i.e. steel structure repair.

4.0 MANPOWER

4.1 Section Manager shall be the over-all responsible for the implementation of this method statement and for all the task and functions concerning construction activities.

4.2 Safety Officer shall ensure that all works to be carried out should meet the Project’s Health, Safety, Environment (HSE) and Security standard.

4.3 QC Inspector shall be responsible of the inspection of the work in accordance to Saudi ARAMCO Project Standards and Specification.

4.4 Welding Supervisor & Foreman shall directly control, organizing and planning the repair activities. Responsible at site for the implementation and compliance with the method statement. Manpower shall be the following but not limited to as listed below.

- Helper/Fire Watcher

- Structural Fitter

- Quality Control Engineer/Inspector

- Safety Officer.

5.0 TOOLS AND EQUIPMENTS

5.1 Tools shall include but not limited to as follows:

- Clamps (long arm).

- Oxy fuel torch.

6.0 METHODS / PROCEDURES

6.1 Preparatory Works

6.1.1 Secure work permit from JGC/Daewoo prior to start of the activity.

6.1.2 Prepare all materials, tools & equipment and manpower needed for the job.

6.2 Heating

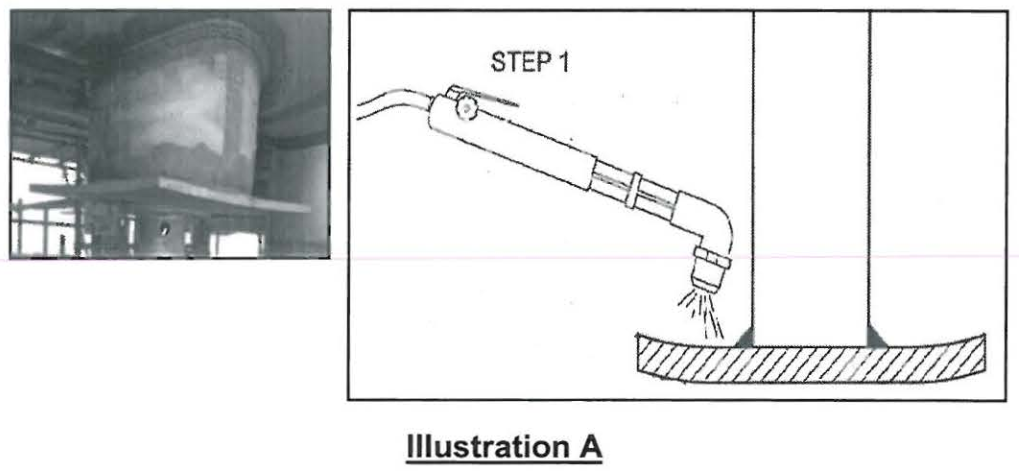

6.2.1 Apply heat using the oxy-fuel torch on the warped portion of the slide plate. Refer to Illustration A below.

6.2.2 Maintain the heat throughout the affected portion not higher than 250 °C until the heat is uniformly distributed.

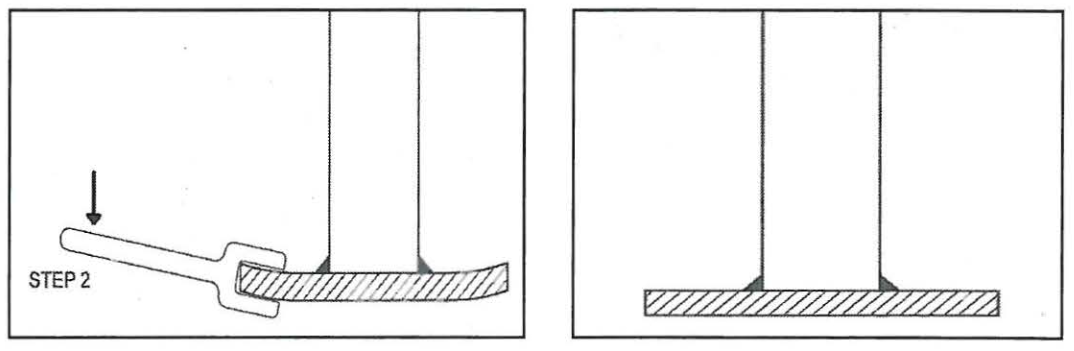

6.2.3 Removed the oxy-fuel torch and proceed to Illustration B below.

6.2.2 Maintain the heat throughout the affected portion not higher than 250 °C until the heat is uniformly distributed.

6.2.3 Removed the oxy-fuel torch and proceed to Illustration B below.

9.0 ATTACHMENT

9. 1 Attachment 1 Job Safety Assessment