This article establishes minimum requirements for the use of Resistance Temperature Detectors (RTD) in process plants and main keywords for this article are Resistance Temperature Detector RTD Design Requirement . Definitions Resistance Temperature Detector RTD. RTD Application Considerations. References RTD.

References Resistance Temperature Detector RTD

Reference is made in this standard to the following document.

American Petroleum Institute (API)

RP 550 Manual on Installation of Refinery Instruments and Control Systems

RP 551 Process Measurement Instrumentation

Definitions Resistance Temperature Detector RTD

For the purpose of understanding this standard, the following definitions apply.

Calibration. A test during which known values of measurand are applied to the transducer and corresponding output readings are recorded under specified conditions.

Drift. An undesired change in output over a period of time, which change is not a function of the measurand.

Hermetically Sealed Device. A device which is sealed against the entrance of an external atmosphere and in which the seal is made by fusion.

Padding Resistor/Padding. Padding resistor is a resistance network, used to alter the calibration of a Resistance Temperature Detector (RTD).

Resistance. The opposition to the flow of electricity in an electric circuit measured in ohms.

Resistance Temperature Detectors (RTD). A temperature measuring device in which the sensing element is a resistor of a known variation in electrical resistance temperature.

Smart Transmitter. A programmable transmitter, capable of performing calculations, self-diagnostics, and reporting faults, which communicates from a remote location.

Thermometer. An instrument for measuring temperature which measures a change in density or electrical resistance of a temperature-sensitive material.

Resistance Temperature Detector RTD Design Requirement in Process Plant

- The installation of RTDs shall conform to API-RP 550/551.

- Resistance Bulbs

- Resistance bulbs shall be of 100 ohm (at 0 °C) platinum, a = 0.00385, utilizing a three wire system. Use of other types of RTDs shall be at the discretion.

- RTDs shall be metal sheathed, 316 stainless steel, and mineral insulated with 6 mm (1/4 inch) stem diameter.

- RTD head shall be weather proof and made of aluminum.

- All conductors for field runs on individual RTD shall be of equal length.

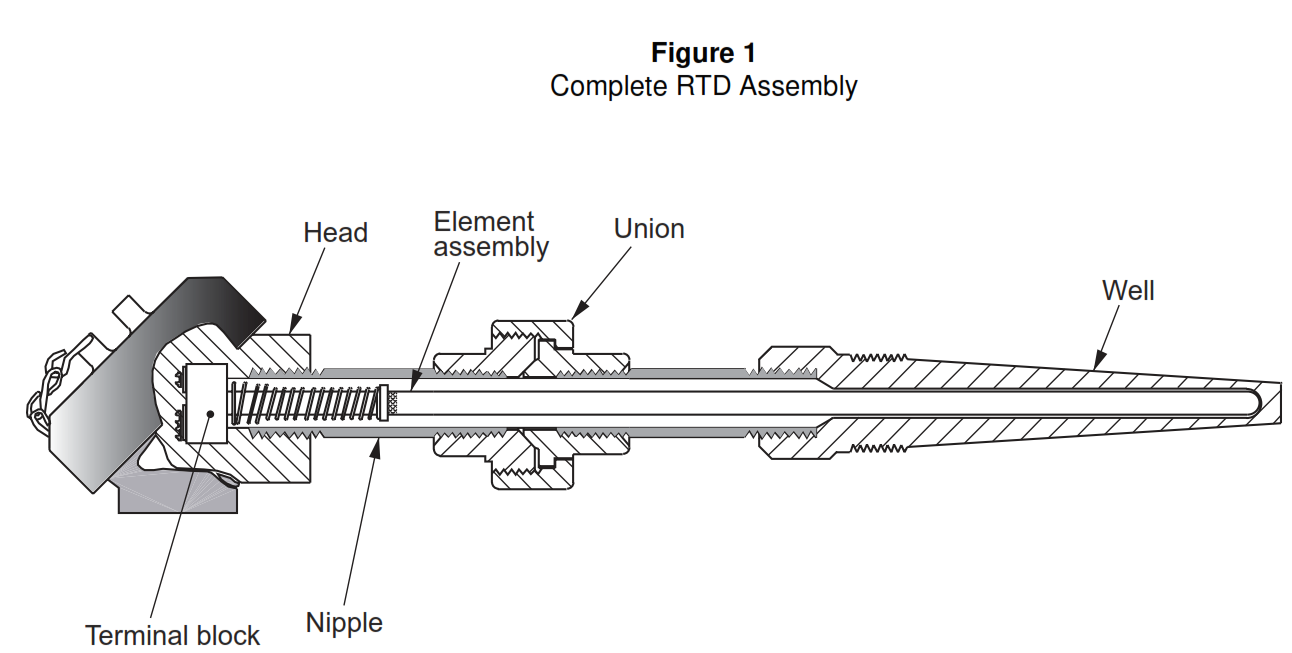

- Typical RTD assembly shall be as shown in Figure 1 below.

COMPLETE HEAD, NIPPLE, UNION, NIPPLE, WELL AND ELEMENT ASSEMBLY

RTD Application Considerations

- The RTD assembly shall include a 1/2” x 3” nipple, 1/2” union and 1/2” x 3” nipple to assemble the RTD to the aluminium head. The two nipples shall be 316SS.

- The RTD assembly consisting of sensor, thermowell and connection head (or direct mounted transmitter) shall carry the hazardous location certification for the site of installation.

- The following is recommended for maximum accuracy:

- All industrial applications shall have three-wire configuration. The four wire configuration shall be used only where extreme accuracy is required for calibration purposes or for use with four-wire linear

bridges. - Padding shall be avoided. It involves the addition of resistors either in series or shunted across the sensing element. This alters the thermometer curve completely.

- Vendor calibration of RTDs’ shall be verified at operating temperature at plant site.

- Location of transmitters in temperature controlled areas is recommended where high accuracy is required. Ambient temperature, drift characteristics, and alteration of calibration by 0.1 °C will effect the

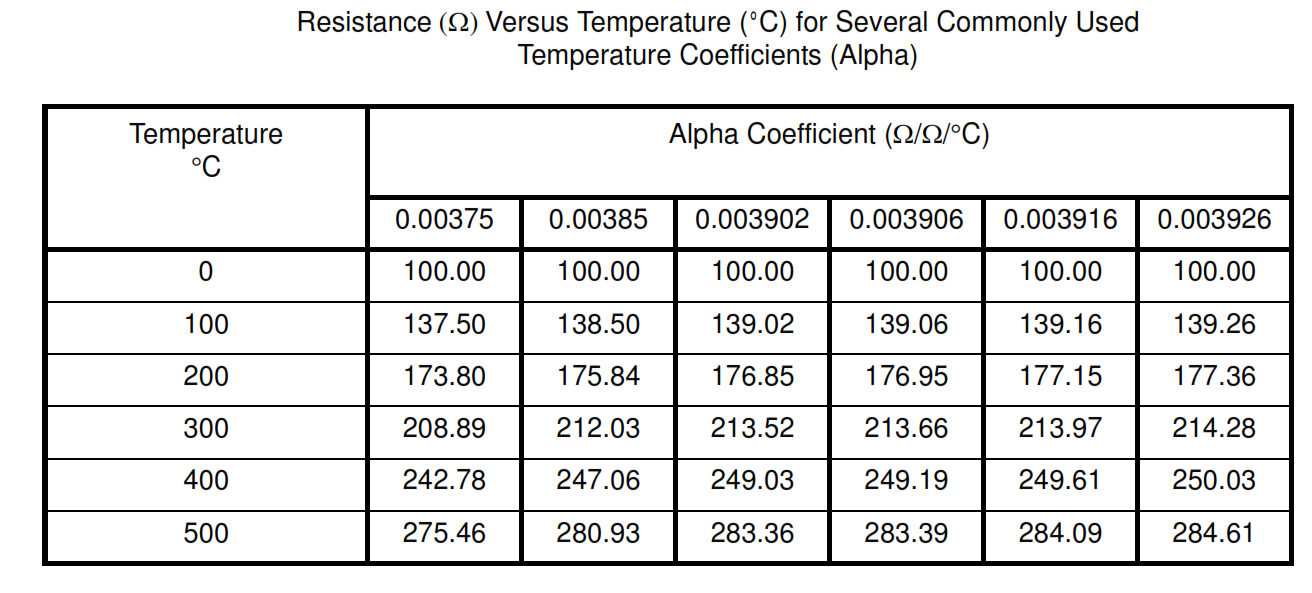

accuracy of RTD. Some “Smart” transmitter models compensate for temperature to the degree that they may not require a sheltered location. - Replacement of RTD without recalibration of readout equipment shall be done only when it is known that the two RTDs were made to the same calibration curve. Table I shows the range of resistance values for six commonly used alphas. A change in alpha without corresponding recalibration of equipment could, in extreme cases, cause errors of greater than 20 °C (68 °F).

- Wire insulation shall be compatible with ambient temperature. For ambient temperature upto 100 °C, Polyvinyl chloride is acceptable. Above 100 °C non asbestos insulation is required.

Table 1

Resistance (ohm) Versus Temperature (°C) for Several Commonly Used Temperature Coefficients (Alpha)