DISPLACER TYPE LEVEL TRANSMITTER CALIBRATION

There is lot of methods for level measurements, one of them is indirectly level measurement when column of liquid exerts pressure. In second sense we can say this is pressure measurement.

The pressure that liquids exerts on base vessel is directly proportional liquid level of vessel. If the liquid level increases at base of vessel, pressure will also increase.

Mathematically this relationship will be

P = S.H

Here P = Pressure of the liquid (Pascal) ; S = Density of Liquid (Nm3/hr) ; H = level of liquid or column of liquid

If the specific gravity of liquid is constant. We can tell the liquid level by measuring pressure value in base of the tank or any vessel. For this purpose we can use differential pressure transmitters which is commonly used now a days to measure the pressure at the base of tank.

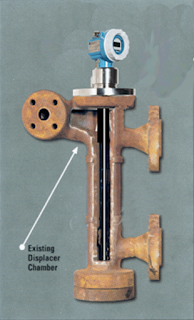

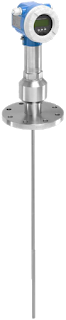

We know that differential pressure transmitters measure the pressure but they are used for level measurements. DP transmitter are called Level transmitters. A displacer type level is most commonly level application used for the closed vessel as well as interface level where the two process liquid having diffrent specific gravity.

- No upper blocking distance.

- Independent of density changes.

- Less influence by buildup.

- Independent of foam.

- Less influence by corrosion.

- No moving parts.

- Independent of vibration.

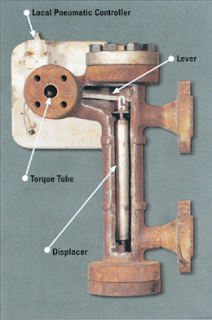

WORKING PRINCIPLE OF DISPLACER TYPE LEVEL TRANSMITTER

Its works on the Archimedes’ principle or the law of buoncy, the law say the weight of the substance immerse in the liquid is equal to the amount of liquid displaced by the body.

Now as per the question the way to calibrate the displacer level first we have to isolate the level troll chmber from its process by isolating the root valves, then drain the liquid presence inthe chamber, connect the PVC transparent tube at the bottom of the chamber and then start filling the water in the tube.

CALIBRATION OF DISPLACER TYPE LEVEL TRANSMITTER

To calibrate the displacer type LTs by fixed in the work/bench, First remove the head, clean displacer and chamber and assemble, fix the calibration setup (drain isolation, clear tube and marked scale).

Calculate 100% position of fluid filling, by the Specific gravity of the fluid where the LT being used. (Ex: If specific is 0.8, then the 80% of the displacer height to be marked in chamber due to the water used for calibration), and mark every 25% in chamber ouside for reference.

- Fill the water and check the transmitter/board/sensor response approximately.

- Fill the water till the displacer touches. and checkk 0% and adjust to 4mA.

- Fill the water till 100% to check span and adjust 20mA. (If the LT s not responding, replace LVDT/board and chk)

- Repeat zero and span check 4-5 times and the check every 25 % rising and falling.

If ok, the prepare the calibration report and tag

Please read also: Basics and Inferential of level transmitter