1. SCOPE

2. DEFINITION AND ABBREVIATION

3. REFERENCES

4. DUTIES AND RESPONSIBILITIES

5. MATERIALS

6. TOOLS AND EQUIPMENT (by vendor)

7. WORK PROCEDURE

8. TYPICAL SECTION TO BE TREATED FOR ANTI-TERMITE

9. HEAL TH, SAFETY AND ENVIRONMENTAL PROTECTION MANAGEMENT SYSTEM

10. RISK ASSESSMENT AND SAFETY MEASURE

11. ATTACHMENT

1. Scope of Work

Termites considered the most dangerous household insects. They attack wooden doors, furniture and kitchen kits, destroying all household property, in fact any material containing Cellulose. This method statement explains how to treat and protect the building from termite attack. Anti-termite will be applied on Building substructure foundation side surfaces which directly in contact with soil.

The buildings to be treated from termite attack are; Sub Stations, Process Interface Buildings, AFD building. All the specifications written herein are based on the issued Building Construction Specifications, Saudi Aramco Engineering Standard and other related International Standard references applicable for this report to Saudi Aramco.

2. DEFINITION AND ABBREVIATION

3.REFERENCES

SAUDI ARAMCO ENGINEERING STANDARDS

SAES-M-100 Saudi Aramco Building Code (Sec. 2304.11.1)

INDUSTRY CODE

IBC 2009 – International Building Code.

4. DUTIES AND RESPONSIBILITIES

Site Manager

The Site Manager shall be responsible for the over-all direction, monitoring coordination and control of general works and the over-all Health and Safety standards and procedures of the project.

Construction Manager

The Construction Manager shall be responsible for the over-all implementation and monitoring of all the activities involved in this scope of work.

QA/QC Inspector

The QA/QC Inspector shall be responsible for the implementation of construction specification and standards and see to it that this written method statement of the work shall be carried out.

Site Supervisor

He shall be directly involved in the planning and execution of all activities involved in the reinforced concrete works and observation of site condition. He shall likewise ensure the implementation of quality plans. He shall, prior to start of work, prepare Safety Action Plan that must be implemented and observed during the entire activity.

Foremen

The Foremen in their respective areas shall be responsible for the direct execution of works involve in the repair activities. They shall implement the works according to the plan and shall directly control and give instruction to the working personnel. He shall also be responsible on the proper tools and equipment used for this type of work.

Safety Manager/Supervisor

Safety Manager/ Supervisor shall review prior to the start of the work, Safety Action Plan that must be implemented and observed during the execution of the work. He shall review the applications for work permits, if required, from safety point of view.

MATERIALS

- BIFLEX TC/ Bifenthrin

- Water

6. TOOLS AND EQUIPMENT (by vendor)

- Car Mounted Power Spraying Machine H.P.

- Hose Reel (50 Mtr to 100 Mtr).

- Spray Gun.

- Probe Injector.

- Car Mounted Formulation Tank 400 Ltrs Capacity.

- Single or Double Cabin P/UP.

- Hand tools.

7. WORK PROCEDURE TERMITE CONTROL | METHOD STATEMENT

1.1 Preparation

1.1.1 Remove all wooden pieces, concrete debris, plastic strips, tree stump roots, deleterious materials etc.

1.1.2 The entire area to be treated shall be barricaded to avoid harmful effects of chemicals.

1.1.3 Compaction test and inspection of soil shall be done before application of anti-termite.

1.1.4 Materials, tools & equipment shall be checked upon commencing of the work.

1.1.5 Coordinate and confirmation of people site access and the water source accessibility on site.

1.1.6 Only authorized applicator is allowed to perform the anti-termite treatment. The mixing proportion to water and rate of application shall be in accordance with the manufacturer’s recommendation.

1.1.7 The Method Statement (MS), Material Safety Data Sheet (MSDS) and Material Approval Request (MAR) and Vendor/Applicator approval must be on hand with the Site Supervisor and QC Inspector before commencement of the work. All construction related tests, backfilling and compaction shall be approved by the Saudi Aramco prior to treatment.

1.2 Application

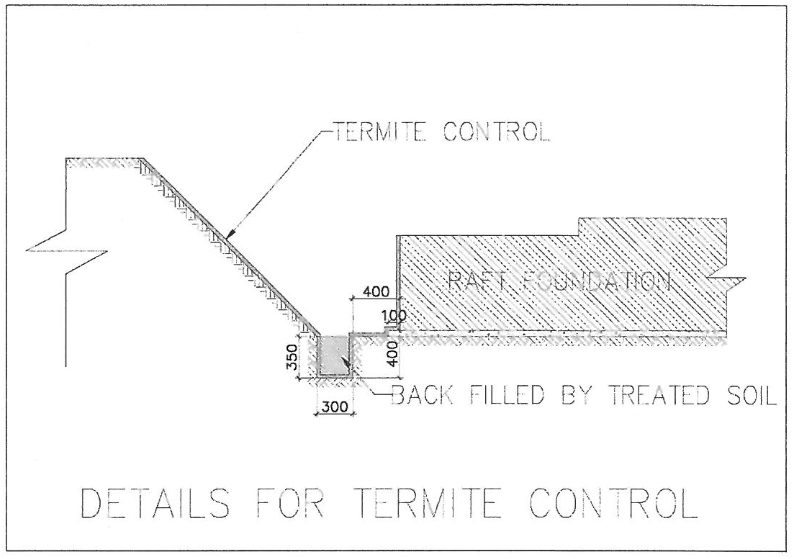

The anti-termite will be sprayed around the footings, slab on grade, columns and the outermost concrete structure around the building which is directly contact with soil.

1.2.1 Concrete Slab foundation

a. With the same solution of approved Anti-termite material, apply with the recommended spreading rate into the concrete foundation surfaces of sides.

b. Backfill around the foundation after letting the anti-termite subside within 2 hours. Back filling must be done within 2 to 24 hours after anti-termite application.

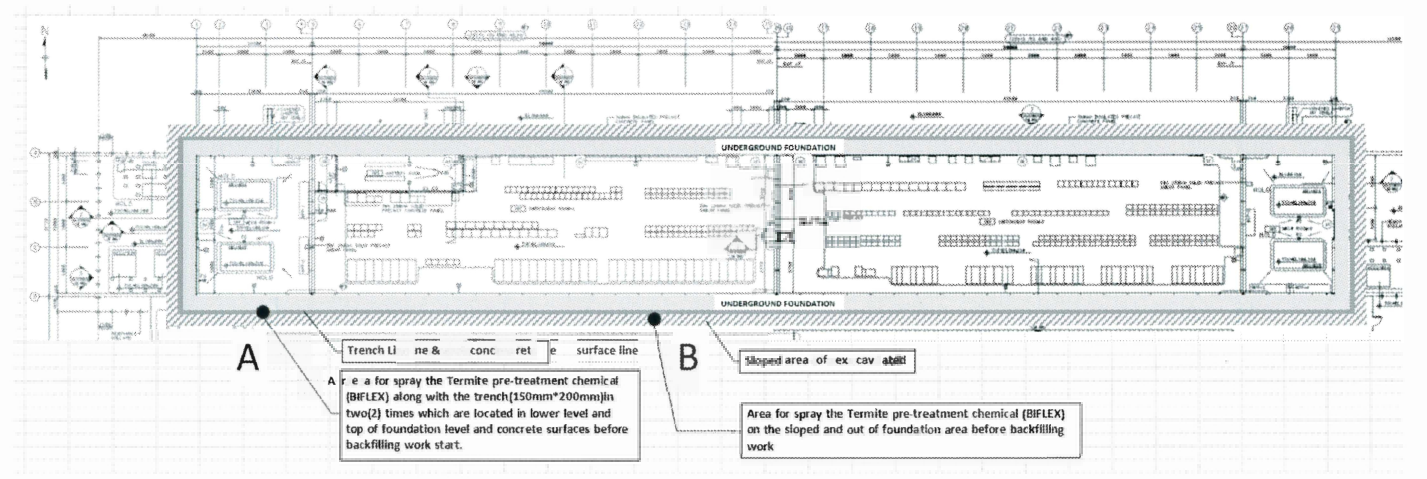

1.2.2 Perimeter of Building

a. Make a trench around the perimeter of slab with the size 150mm wide and 200mm in depth for lowest level & top of foundation (Two times) throughout the outermost perimeter of the building.

b. A solution of Approved Anti-termite material diluted with water at a recommended mix proportion will be sprayed into the trench along the external perimeter of the building. Spreading rate shall be in accordance with the manufacturer recommendation.

c. Backfill the trench within 24 hours of treatment to avoid rapid evaporation.

1.2.3 Treatment for other areas

a. In addition to the areas to receive anti-termite treatment, apply treatment solution directly below the expansion joints, isolation joints, around plumbing pipes and electrical conduit penetrating to concrete slab.

b. Reapply anti-termite on the disturbed soil by subsequent excavation, grading and other areas disturbed caused by material embedment.

c. The rate of application shall be in accordance with manufacturer recommendation.

8. TYPICAL SECTION SUBJECT FOR ANTI-TERMITE TREATMENT

9. Health, Safety and Environmental Protection Management System

1.1 General Safety Procedure

The Owner Safety Supervisor shall carry out the safety site inspections to ensure that safety requirements laid out in the HSE Plan are followed during the execution of the work. He shall review the prepared HSE Plan and secure work permit if required prior to start of any activity.

1.2 HSE Plan

(See Previous Submitted Documents with Reference: VE-698015: HSE MANAGEMENT PLAN)

1.3 Equipment, Tools, and Materials Inspection

The spray machine shall be visually inspected to check any defective parts and shall have clearance for use from Safety staffs.

1.4 Power hand tools shall be checked of any loose and exposed wiring. It shall be marked with color-coded tape signifying compliance to safety inspection requirement.

1.5 PPE Requirements

Neoprene gloves, respirators protection, safety glasses, face shield, overalls (disposable).