This article describes the construction practices associated with underground excavation and installation of conduits, manholes and cables. Main keywords for this article are Trenching Excavation Requirements, Trenching Excavation for Direct Buried Conduit, Concrete Encased Conduit, Duct Bank Construction, Manhole Installation.

Trenching Excavation Requirements in Plants

- The depth of underground electrical duct banks and cable installations shall be in accordance with article Click Here and all drawings.

- Trench sides shall be appropriately sloped and/or shored to prevent cave-ins. The Contractor shall be responsible for coordinating the trenching work with other discipline underground work, to resolve conflicts in level and/or space allocation.

- The Contractor shall submit a request for an excavation permit and include a trench layout drawing showing coordinates and elevations as well as any crossings with existing pipe/cables. No excavation shall take place until the permit is issued.

- The trench should be excavated from one manhole location to the next before grading the trench or laying conduit is attempted. It is possible that obstructions of one kind or another may be countered which will necessitate changing the grade or the route of the trench.

- The depth of the excavation necessary for conduits and directly buried cables depends upon the cover, the depth of the duct bank or cable, the bedding and other buried objects such as pipe. The trench bottom should be level. The levelness of the duct structure is determined by the levelness of the trench bottom. All sharp bends should be avoided in the excavation.

- Trenches should be planned so that the spoil does not interfere with the storage and handling of duct. If the ground in the trench bottom is muddy or wet, the trench bottom should be built up with rock or gravel. The duct structure should be kept dry until the concrete envelope has been poured. The trench must be pumped where there is an excessive amount of water.

- The Contractor shall repair any damage to existing services which may occur during trenching operations. All trenches shall be checked for depth, width and pitch prior to installing any raceway or forms.

Conduit Installations

Trenching Excavation for Direct Buried Conduit or Non-Concrete Encased

- Non-concrete encased, direct buried conduit installations must be approved by company. Authorized installations shall be in accordance with the following requirements.

- The installation of conduit without concrete encasement is similar to that for concrete-encased conduit.

- All trenches shall not be less than 100 mm (4 in) below the desired elevation of the bottom of the conduit.

- Holes and depressions shall be filled and tamped to thoroughly.

- Fill bottom 100 mm (4 in) of the trench with selected backfill free from stones and tamp lightly.

- Bed the conduit in the selected backfill one-fourth to one-third of the conduit diameter. Under no circumstances should bricks or other supports except the bedding be used to bring the conduit to elevation.

- Backfill with material as required per Backfill Requiement paragraph, for 100mm (4in.) over top of conduit. Install red concrete tiles or pour 25 mm (1 in.) thick layer of red concrete to extend 100 mm (4in.) in width past outermost conduits. Backfill to grade with native soil.

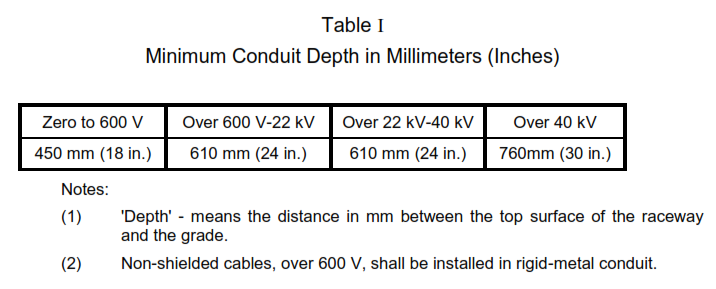

- The minimum depth of direct buried conduit shall meet the requirements of Table 1.

- Rigid-metal Conduit

Trenching Excavation for Concrete Encased Conduit – Duct Bank

- Underground duct banks shall be routed to manholes and pull boxes located along the duct bank as shown on the drawings. Installation shall be as defined in the installation details and per the requirements of this specification.

- Underground duct banks running under roadways and other areas of high loading shall be concrete encased rigid galvanized steel conduit.

- The top of the concrete envelope of the duct bank shall be a minimum of 610 mm (24-inches) below grade. This minimum shall be increased to 610 mm (24 in) under roadways .

- The concrete envelope for conduit stub-ups shall extend 150 mm (6 inches) above grade.

- The concrete shall meet strength requirements of. Concrete mixture shall have pea gravel aggregate not exceeding 19mm (¾ inch) in size.

- The concrete shall be pigmented with a minimum of 6 kg of red oxide additive per cubic yard.

- Concrete shall be poured with as low a slump as possible to allow flow of concrete around all the conduits.

- Pour joints shall not occur at a conduit coupling joint.

- Duct banks comprised of RGS conduits are not required to be reinforced.

- Duct banks comprised of PVC conduits shall be reinforced with steel rebar. Conduit supports shall be tied to the reinforcing steel to prevent conduit float.

- The concrete envelope surrounding the conduits shall have a minimum thickness of 76mm (3-inches) on the top, bottom, and sides. Where reinforced sections of duct bank are required, the thickness of the concrete envelop shall be increased to allow an additional 51mm (2-inches) of concrete around the reinforcing bar on each side.

- During pouring operation all open ends of conduit raceway shall be capped.

- All conduit raceway shall be capped after installation until final connection to equipment is made.

- A grounding or fault current conductor shall be installed within the concrete encasement of the conduits or ducts.

- All U/G conduits shall be proof-tested by running the proper sized wire brush and/or mandrel through the conduit system after concrete has been poured.

Duct Bank Construction Methods

This section describes two general methods used in laying conduit for concrete encasement and the precautionary measures necessary to obtain a satisfactory installation.

- The methods permitted to be used in laying conduit for concrete encasement are the “built-up” method and the “tier-by-tier” method. Each method has its own advantages. A denser and more uniform concrete between the conduits is obtained by the tier-by-tier method. The overall dimensions of the concrete envelope may be less than those for the built-up method.

Note: When installing ducts by the built-up method, ducts should be separated by 50mm (2 in.) for two vertical rows and by 76mm (3 in.) for three or more vertical rows. The 76mm (3 in.) separation can be reduced to 38mm (1-1/2 in.) when the ducts are installed by the tier-by-tier method.

-

Built-up Method

a. The built-up method of laying the conduit is preferred. For most installations, the conduit may be set in place in the trench on precast concrete or plastic spacers or separators. In the case of unstable soils, it may be necessary to support the conduit structure on pile bents and a reinforced concrete slab.

b. In this method, the conduits are all assembled in place in the bank with the conduit supported on spacers.

c. The maximum intervals between spacers on curved sections should not exceed 1200mm (4 ft.)

d. As the laying of the conduit proceeds, the conduit layers are tied together with pieces of heavy twine (not wire). In this manner, a rigid conduit structure is progressively built up to the height of the full duct configuration. It is recommended that the bottom row of conduits be advanced not more than two lengths ahead of the upper rows.

e. The bank then is concreted as a unit with a monolithic pour.

f. With this method, it is necessary to use care when pouring concrete. It shall not be poured directly onto the duct structure, but shall be directed by a splash board in and around the rows of ducts so that the trench wall absorbs the shock. Portable chutes, specially constructed, may be used to break the fall of concrete as it drops in the trench.

g. Tamping shall be done in a thorough manner on the leading edge of the concrete while pouring in order to avoid serious faults such as voids and air pockets. It also shall be done carefully with a wooden tamper. Liberal and continuous tamping is necessary to ensure the flowing of concrete between and under the individual conduits.

h. There is a tendency for the duct bank structure to float during the concrete pour. The conduit position shall be maintained by bracing the ducts to the wall of the excavation or form work with suitable lengths of wood and chocks or jacks. The wood lengths shall be removed and the voids filled with concrete before the concrete envelope has had a chance to set completely.

i. An alternate approved method of holding the duct structure in position is to place 22 to 34 kg (50- or 75-pound) weights on the top layer of conduit about every 5 1500mm (5 ft.) to 2400 mm (8 ft.). These weights also should be removed and the voids filled with concrete before the concrete has set.

j. Sections of duct banks spanning open gaps over sewers and water mains, etc, shall be reinforced with rebar. -

Tier-by-tier method

a. The tier-by-tier method used for laying fiber duct is a more costly installation.

b. A foundation of concrete shall be placed on the bottom of the trench, which has been graded. The thickness of this base shall be gauged by grade stakes which shall be placed in the center of the trench.

c. Upon this concrete base, the bottom tier of ducts is laid, the horizontal separation of ducts being maintained by wooden combs placed about 1500mm (5 ft.) apart along the axis of the duct bank. The teeth of the comb are as wide as the specified horizontal separation between ducts, and the cross-bar as thick vertically as the specified vertical separation of the ducts.

d. The space between the ducts of this first tier is then filled with concrete and the ducts covered to the top of the comb separators, which are then removed for use on succeeding tiers of ducts.

e. This method of laying is repeated in sections of about 15m (50 ft.) in length, tier-by-tier, until the required multiple of ducts has been laid. In this method of laying the concrete, mix should be comparatively dry to ensure a firm bed for installing each tier.

f. This method may be used advantageously in cramped quarters since the spacing between ducts may be maintained at 38mm (1-1/2 inches) minimum, regardless of the number of vertical rows in the duct bank.

g. In order to make an economical installation of duct by this method, close coordination between the various trades involved in trenching, laying the duct, concrete work, etc, is necessary. laying the concrete, mix should be comparatively dry to ensure a firm bed for installing each tier.

f. This method may be used advantageously in cramped quarters since the spacing between ducts may be maintained at 38mm (1-1/2 inches) minimum, regardless of the number of vertical rows in the duct bank.

g. In order to make an economical installation of duct by this method, close coordination between the various trades involved in trenching, laying the duct, concrete work, etc, is necessary.

Manhole Installation

- Manholes shall be installed in the locations as shown on the drawings and as necessary to meet cable pulling requirements.

- Construction joints may be omitted If all concrete is poured monolithically.

- Use of duplex or twin handholes result in construction savings and provide localized service and inspection centers.

- When desirable to remove and reuse forms for duplicate manholes, the pulling eye bolt can be unscrewed and replaced for form removal after it is poured.

- The minimum headroom in the manhole should be 1980mm (6 ft-6 in.).

Handhole Construction for Trenching Excavation

A shallower form of manhole, known as a handhole, may be installed where smaller chambers than those usually associated with manholes will provide sufficient and suitable space for cables and any associated equipment to be installed therein.

Handhole construction is similar to that for manhole construction except as outlined below.

1. No handholds should be installed in roadways or other areas that are subject to vehicular traffic. This requirement is a safety measure in-tended to protect workmen.

2. Frames and covers for handholes (service pits, boxes, etc) should provide the maximum working space for the personnel with the covers large enough to permit working from above the opening. Metallic covers and frames which form the entire roof of the handhole should be used.

3. Precast concrete-type construction is suitable for handholes where soil and location conditions permit. They may be cast as one unit, or consist of a separate pipe or caisson with poured-in-place concrete floor.

4. Poured-in-place concrete walls and bottoms for handholes up to 1m (3 ft.) in depth.

5. The width and length of handholes shall be designed to allow adequate space for properly bending and training of cables, for racking, offsets, etc.

6. Metallic covers and frames which form the handhole roof must be grounded per NEC Article-250 when enclosed circuits exceed 150 volts.