This article is about UPS / DC Equipment and Battery Rack, Installation and Pre-Commissioning & Requirements of Electrical Power System Systems as per International Codes and standards for Commercial Buildings, Plants and Refinery Projects.

UPS DC/AC Inverter Material Selection Criteria & Checklist

QC Before Installation- Inverters shall conform to all applicable requirements, standards, and specifications prior to release to be used as part of work.

Incoming Inverters shall be visually inspected for damage / defects occurred during transportation.

Inverters shall be new and unused.

Inverters shall be in accordance with the Saudi Aramco-approved project-specific design drawings, diagrams, schedules, lists, databases, and associated design documents.

Check that the Contractor or it’s Saudi Aramco approved third party inspector performed the quality activities at the supplier and sub-supplier locations as required by the inspection level assigned for the materials and equipment identified in SAER-1972 Inspection Requirements.

Fuses shall be provided to protect the inverter power semiconductors. Blown fuse shall be indicated by LEDs or an alphanumerically displayed message on the UPS monitoring screen.

UPS-A output shall be designated as source A, and UPS-B output shall be designated as source B.

Inverters supplied under this specification shall be pulse-width modulation (PWM) design. Use of ferromagnetic control type inverters is not permitted.

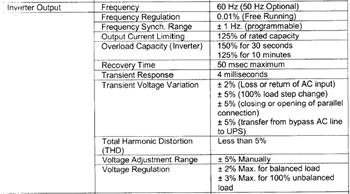

The single-phase output inverter voltage in steady state condition shall be within + 1% of the nominal voltage. The steady state limits shall be applicable for any load combination, load step change from no-load to 100% load, minimum to maximum dc bus voltage and loss or return of mains power supply.

Transient response shall not exceed plus-minus 5% voltage variation from the nominal value for transfers to bypass AC line or return form bypass AC line, and/or load step change form 0-100%.

Systems “A” and “B” shall have separate battery banks such that each battery banks shall be sized for 50% of the required total battery backup time.

A solid state make-before-break switch, rated for continuous operation at 125% of the UPS rated power shall be connected between the bypass and the load.

The inverter output shall be connected to either a contactor or a solid state static switch of make-before-break connection and rated for continuous operation.

The inverter side static switch function may be integrated into the inverter’s IGBT switching devices.

All internal devices and components shall be provided with an identifying number or a nameplate to identify the item and its function. Nameplate abbreviations shall match the item description shown on the UPS schematic drawings.

“Instruction Manuals

Each system shall be provided with instruction manual(s) including the following information as a minimum. The required number of sets shall be as specified on the buyer’s Non-Material Requirements for Interruptible Power Supply (UPS) Form NMR-9597.

a) Installation & commissioning instructions

b) Operating instructions

c) Wiring & schematic diagrams

d) Service instructions with calibration & trouble shooting guide

e) Factory Test procedures & Certified test reports”

UPS enclosure doors shall be hinged and designed to open at least 120 degrees to facilitate maintenance access.

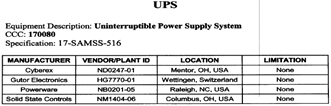

Check that the UPS system are supplied from the approved manufacturer as per Regulated Vendors List for Electrical Equipment. SAES-P-101, (09 June 2007 Issue) SAES-P-101, (29 Feb. 2004 Issue)

Check the performance requirement of AC Inverter nameplate data.

International Standard and Codes for UPS DC/AC Inverter Material

- Non-Hazardous Indoor Enclosures, Installation and Pre-Commissioning

- Boxes, Enclosures, and Accessories Materials Selection & Requirements

3. SAES-P-103 UPS and DC Systems, 02 June 2008

4. SAES-P-101 Regulated Vendors List for Electrical Equipment, 09 June 2007

5. 17-SAMSS-516 Uninterruptible Power Supply System, 13 August 2007