3-wire transmitters need an extra wire to ensure they get sufficient operating current (more than 20 mA) for proper functioning. This additional wire usually carries the same voltage as the loop power supply, often 24 VDC, and manages the total current needed for both the device’s operation and the loop current. Check out Figure 23 for a visual representation.

What is 3-Wire Transmitter?

In the realm of process control and industrial automation, 3-wire transmitters emerge as a versatile solution that strikes a balance between power requirements and precision. These transmitters, distinguished by the inclusion of an additional wire, offer unique advantages in certain applications. Let’s explore the fundamentals, operational principles, advantages, and applications of 3-wire transmitters.

Wiring Diagram

Fundamentals of 3-Wire Transmitters:

The distinctive feature of 3-wire transmitters lies in the presence of an extra wire, often referred to as the “sense” or “excitation” wire. This third wire serves a crucial purpose – providing additional operating current beyond the typical 4 to 20 mA loop current. While the loop current handles the transmission of the process signal, the third wire ensures that the transmitter receives sufficient power to operate optimally.

Working Principle of 3-Wire Transmitters

In a 3-wire configuration, the third wire is usually connected to the same voltage source as the loop power supply, typically 24 VDC. This wire carries the total current required for both the operation of the transmitter and the loop current. By decoupling the power supply for the transmitter from the loop current, 3-wire transmitters can ensure consistent and reliable performance.

The loop current, responsible for conveying the process signal, still flows through the traditional two wires, maintaining the simplicity of signal transmission. The third wire handles the additional power requirements, contributing to the stability and accuracy of the transmitter.

Advantages of 3-Wire Transmitters:

- Enhanced Power Supply: The inclusion of the third wire allows 3-wire transmitters to receive higher operating currents, ensuring robust performance even in demanding applications.

- Greater Precision: By separating the power supply for the transmitter from the loop current, 3-wire configurations minimize the impact of voltage drops and power limitations, resulting in increased precision in signal transmission.

- Flexible Power Options: The availability of a dedicated sense wire provides flexibility in choosing the power source for the transmitter, accommodating various voltage requirements.

Considerations:

- Installation Complexity: While offering advantages, the addition of a third wire introduces a level of complexity to the installation process compared to 2-wire transmitters.

- Wiring Costs: The inclusion of an extra wire may result in slightly higher wiring costs, and engineers must weigh this against the benefits of enhanced power and precision.

Applications of 3-Wire Transmitters:

- High-Precision Industrial Processes: Industries that demand high precision in process control, such as chemical manufacturing and laboratory applications, benefit from the enhanced accuracy of 3-wire transmitters.

- Long-Distance Installations: Suitable for situations where longer distances between the control system and the transmitter are involved, mitigating the impact of voltage drops.

- Applications Requiring Varied Power Sources: The flexibility in power options makes 3-wire transmitters suitable for scenarios where different voltage sources are preferred or available.

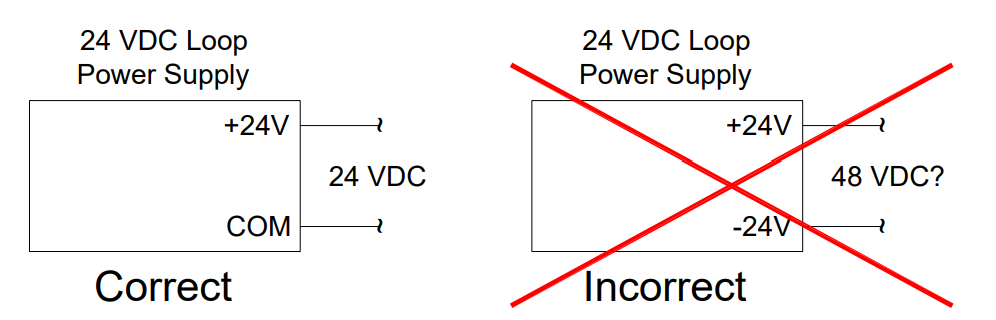

Loop Power Supply Terminal Designations:

The positive terminal of a 24 VDC power supply is commonly denoted as “+24VDC” or a similar designation. However, it’s important to note that the common or return terminal should not be represented as “-24VDC.” This designation is inaccurate because it suggests a 48 VDC difference between the +24VDC and -24VDC terminals, which is not the case.

In conclusion, 3-wire transmitters represent a strategic integration of power and precision in process control systems. While introducing an additional wire, they bring enhanced stability, accuracy, and flexibility to applications where these attributes are critical. As industries continue to advance, 3-wire transmitters stand as a testament to the ongoing pursuit of efficiency and precision in the dynamic field of industrial automation.

Read Also:

What is 2-Wire Transmitter? Wiring Diagram, Working Principle, Connection to PLC

What is 4-Wire Transmitter? Wiring Diagram, Working Principle, Connection to PLC