Polytetrafluoroethylene, commonly known as PTFE, is a remarkable polymer that has revolutionized various industries due to its exceptional properties and versatile applications. PTFE is renowned for its non-stick nature, high-temperature resistance, chemical inertness, and low friction characteristics. In this comprehensive article, we will delve into the world of PTFE, exploring its history, properties, production, and wide-ranging applications across industries such as manufacturing, automotive, aerospace, and healthcare.

1. Introduction to PTFE

What is PTFE?

Polytetrafluoroethylene (PTFE) is a synthetic polymer consisting of carbon and fluorine atoms arranged in a repeating chain-like structure. It belongs to the family of fluoropolymers and is renowned for its exceptional chemical resistance, low friction coefficient, and wide temperature tolerance. PTFE is a white, waxy solid that is inert to most chemicals, making it an ideal choice for various applications where resistance to corrosion and high temperatures is required.

Historical Development

PTFE was discovered in 1938 by a chemist named Roy Plunkett while working for the chemical company DuPont. During an experiment with refrigerants, Plunkett stumbled upon a white powder that exhibited unusual properties. This accidental discovery marked the birth of PTFE. In 1945, DuPont patented PTFE, and it was subsequently trademarked as “Teflon,” which has become synonymous with PTFE in many parts of the world.

2. Chemical Structure and Properties

Molecular Structure

The molecular structure of PTFE is characterized by long chains of carbon and fluorine atoms bonded together. This structure results in several unique properties that distinguish PTFE from other polymers.

Key Properties

Non-Stick Nature: PTFE is perhaps most famous for its non-stick characteristics. Its surface is extremely smooth, and it has a low surface energy, which prevents other materials from adhering to it. This property is exploited in various applications, especially in cookware, where it allows food to release easily without sticking.

High-Temperature Resistance: PTFE can withstand a wide range of temperatures, from extremely low cryogenic temperatures to very high temperatures without significant degradation. It retains its mechanical properties and chemical inertness even at elevated temperatures, making it suitable for demanding applications.

Chemical Inertness: PTFE is highly resistant to chemical attack. It does not react with most chemicals, including acids, bases, and organic solvents. This resistance to chemical corrosion makes it an ideal choice for lining pipes and containers in chemical processing industries.

Low Friction: PTFE exhibits a low coefficient of friction, which makes it an excellent material for bearings, bushings, and seals. It reduces wear and frictional heat in moving parts, increasing their longevity.

Electrical Insulation: PTFE is an excellent electrical insulator. It has a high dielectric strength, making it suitable for applications in the electronics and telecommunications industries, where electrical insulation is critical.

3. Production of PTFE

Polymerization Process

PTFE is produced through a polymerization process that involves the polymerization of tetrafluoroethylene (TFE) monomers. The process typically includes the following steps:

- Initiation: The polymerization process is initiated using a chemical initiator or high-energy radiation.

- Propagation: TFE monomers undergo chain-growth polymerization, leading to the formation of long PTFE chains.

- Termination: The polymerization is terminated when most of the TFE monomers have reacted, resulting in the formation of PTFE.

The production of Polytetrafluoroethylene (PTFE) is a complex and highly controlled process due to the reactivity and potential hazards associated with its precursor, tetrafluoroethylene (TFE). Here, we will explore the process of PTFE production, including the polymerization and the role of various chemicals and surfactants.

1. Polymerization of Tetrafluoroethylene (TFE):

PTFE is primarily synthesized through the free-radical polymerization of TFE. The chemical equation for this process is:

n F2C=CF2 → -(F2C-CF2)n–

However, the polymerization of TFE can be hazardous because TFE can explosively decompose into tetrafluoromethane (CF4) and carbon. To prevent this dangerous side reaction, special apparatus and precise control measures are required to avoid the formation of hot spots that might initiate the decomposition. The initiation of polymerization is typically achieved using persulfate, which undergoes homolysis to generate sulfate radicals:

[O3SO−OSO3]2- ⇌ 2 SO–4

These sulfate radicals initiate the polymerization of TFE to form the PTFE polymer chain.

2. Termination with Sulfate Ester Groups:

During the polymerization process, the resulting PTFE polymer is terminated with sulfate ester groups. These groups can later be hydrolyzed to yield hydroxyl (OH) end-groups in the PTFE polymer. Termination is an essential step to control the molecular weight and properties of the final PTFE product.

3. Granular PTFE Production:

Granular PTFE, which is commonly used in various applications, is produced through suspension polymerization. In this process, PTFE is suspended in an aqueous medium. The suspension is maintained primarily through agitation and, sometimes, the use of surfactants. Suspension polymerization allows for the controlled growth of PTFE particles.

4. Emulsion Polymerization:

An alternative method for PTFE synthesis is emulsion polymerization. In this approach, a surfactant is the primary means of keeping PTFE dispersed in an aqueous medium. Emulsion polymerization has been used historically, with surfactants such as toxic perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS). However, due to environmental and health concerns associated with these surfactants, alternative surfactants have been developed and adopted, including Perfluoro 3,6 dioxaoctanoic acid (PFO2OA) and FRD-903 (GenX).

Surfactants in PTFE Production:

Surfactants are crucial in PTFE production as they aid in stabilizing the dispersion of PTFE in the aqueous medium. They help prevent the coagulation or clumping of PTFE particles, ensuring uniform polymerization and particle growth. The choice of surfactants is critical not only for effective polymerization but also for meeting environmental and safety standards.

In recent years, there has been a shift towards using alternative and less toxic surfactants, such as PFO2OA and GenX, to address environmental and health concerns associated with traditional surfactants like PFOA and PFOS.

In conclusion, the production of PTFE is a controlled and complex process involving the polymerization of tetrafluoroethylene (TFE) with the initiation of sulfate radicals. The resulting PTFE is terminated with sulfate ester groups, and various methods, including suspension and emulsion polymerization, are used to produce different forms of PTFE. The choice of surfactants is crucial, with a shift towards more environmentally friendly alternatives in recent years.

Manufacturing Forms

PTFE is available in various forms to suit different applications:

- Virgin PTFE: Pure, unmodified PTFE in the form of sheets, rods, tubes, and custom-machined components.

2. Filled PTFE: PTFE can be filled with various materials, such as glass fibers, carbon, bronze, and graphite, to enhance specific properties like mechanical strength and wear resistance.

3. Expanded PTFE (ePTFE): This form of PTFE is made by expanding the polymer under controlled conditions, resulting in a highly porous material with excellent sealing properties. It is commonly used in gaskets and seals.

Certainly, let’s delve deeper into the enhanced properties and benefits of PTFE when filled with different materials:

4. Bronze Filled PTFE

The incorporation of bronze into PTFE results in a composite material that offers several notable advantages:

- Dimensional Stability: Bronze-filled PTFE exhibits superior dimensional stability. This means it is less prone to changes in shape and size over time, making it highly reliable in applications where precise tolerances are critical.

- Reduced Creep and Cold Flow: Creep is the tendency of a material to deform slowly under constant mechanical stress. Bronze-filled PTFE demonstrates reduced creep, ensuring that it maintains its shape and integrity even under sustained loads. Cold flow, where a material slowly deforms over time at room temperature, is also minimized.

- Enhanced Wear Resistance: The addition of bronze significantly enhances wear resistance. This makes it an excellent choice for applications involving friction and abrasion, where extended component lifespan is essential.

5. Carbon Filled PTFE

The infusion of carbon fiber into PTFE leads to a composite material that offers a range of valuable properties:

- Increased Compressive Strength: Carbon-filled PTFE boasts improved compressive strength. This means it can withstand higher loads and pressures without deforming or failing. This property is especially advantageous in applications with heavy mechanical demands.

- Enhanced Wear Resistance: The presence of carbon fibers significantly enhances the material’s resistance to wear and abrasion. This makes it suitable for components subjected to constant friction and mechanical stress.

- Thermal Conductivity: Carbon-filled PTFE exhibits improved thermal conductivity compared to standard PTFE. This property allows for better heat dissipation, making it suitable for applications where thermal management is crucial.

- Low Permeability: The material maintains PTFE’s low permeability, making it an effective choice for sealing applications where preventing the passage of gases or liquids is essential.

6. Stainless Steel Filled PTFE

The inclusion of stainless steel into PTFE results in a composite material with exceptional attributes:

- High Wear Resistance: Stainless steel-filled PTFE is highly wear-resistant, making it suitable for applications where components are subjected to extreme wear and tear. It can endure harsh conditions and maintain its integrity.

- Outstanding Strength: This material exhibits remarkable strength and stability, even when subjected to extreme loads and elevated temperatures. It retains these properties while still benefiting from the low friction coefficient of standard PTFE.

- Low Friction: Despite its enhanced strength and wear resistance, stainless steel-filled PTFE retains the low coefficient of friction characteristic of conventional PTFE. This ensures smooth movement and reduced friction in mechanical components.

7. Additives and Fillers

PTFE can be modified by incorporating additives and fillers into the polymer matrix to tailor its properties for specific applications. For example:

- Glass Fiber: Adding glass fiber increases the mechanical strength and wear resistance of PTFE. It is commonly used in bearings and seals.

- Carbon: Carbon-filled PTFE improves electrical conductivity and thermal stability. It is used in applications like electrical insulators.

- Graphite: Graphite-filled PTFE offers enhanced lubrication properties, making it suitable for dynamic sealing applications.

Properties of Polytetrafluoroethylene (PTFE)

Polytetrafluoroethylene (PTFE) is a remarkable polymer known for its unique combination of properties. Here are some key properties and characteristics of PTFE:

- Hydrophobic Nature: PTFE is hydrophobic, meaning it repels water and other polar substances. This property makes it ideal for applications like non-stick cookware, where preventing food from sticking to the surface is essential.

- High Heat Resistance: PTFE is highly heat-resistant. It is a thermoplastic polymer that remains a white solid at room temperature, with a melting point of approximately 600 K (327°C or 620°F). This high heat resistance allows it to withstand cooking temperatures without degrading.

- Strength and Toughness: PTFE maintains high strength and toughness, even at low temperatures down to 5 K (−268.15°C or −450.67°F). This property ensures its durability and reliability in various applications.

- Self-Lubrication: PTFE exhibits self-lubricating properties, which means it can reduce friction between moving parts. This makes it suitable for applications involving sliding or rotating components, such as bearings and gears.

- Chemical Inertness: PTFE is highly chemically inert. It is resistant to most chemicals, including acids, bases, and organic solvents. This property makes it valuable in industries requiring resistance to aggressive chemicals, such as pharmaceuticals and chemical processing.

- Resistance to Reactive Metals: PTFE’s carbon-fluorine bonds are highly stable. The only known substances that can affect these bonds are highly reactive metals like alkali metals and, at higher temperatures, metals like aluminum and magnesium, as well as strong fluorinating agents like xenon difluoride and cobalt(III) fluoride.

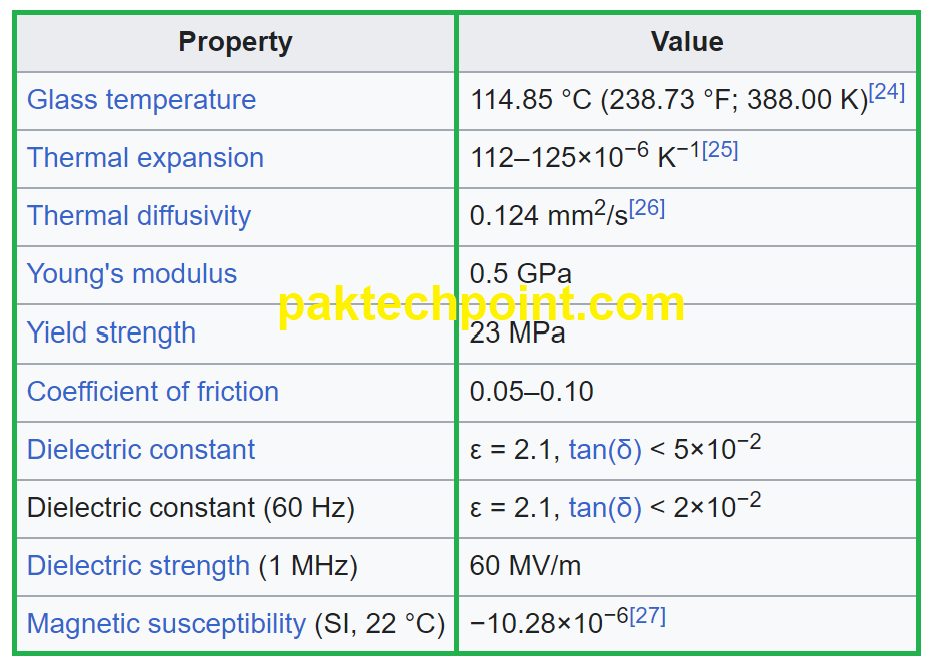

- Low Coefficient of Friction: PTFE possesses a low coefficient of friction, typically ranging from 0.05 to 0.10. This is the third-lowest of any known solid material. Its resistance to van der Waals forces means that it is extremely slippery, to the point that even geckos cannot adhere to it.

- UV Transparency: PTFE is transparent to ultraviolet (UV) light, making it useful in applications where UV transmission is required.

- Creep: PTFE does exhibit creep, which means it can slowly deform under load over time. This property can be a consideration in sealing applications, where it may lead to a loss of performance. Belleville washers are often used to apply continuous force to PTFE gaskets to minimize the effects of creep.

- UV Degradation: While PTFE is UV-transparent, it can severely degrade when exposed to an excimer laser beam due to a heterogeneous photothermal effect. This degradation should be considered in applications involving exposure to specific UV sources.

In summary, PTFE’s unique combination of properties, including heat resistance, chemical inertness, low friction, and self-lubrication, makes it a versatile material used in various industries and applications, from cookware to critical sealing applications in aggressive chemical environments. However, its propensity for creep and sensitivity to specific UV sources should be carefully managed in certain applications.

4. Applications of PTFE

PTFE’s exceptional properties make it indispensable in a wide range of industries and applications. Let’s explore some of its primary applications:

Manufacturing Industry

- Mold Release Agent: PTFE’s non-stick nature is crucial in manufacturing processes, especially in molding operations, where it acts as a release agent, preventing products from sticking to molds.

- Bearings and Bushings: PTFE’s low friction properties make it an excellent choice for bearings and bushings in machinery and automotive applications, reducing wear and improving efficiency.

- Gaskets and Seals: PTFE gaskets and seals are widely used in chemical processing, food production, and pharmaceutical industries due to their chemical resistance and sealing capabilities.

Automotive Industry

- Wire Insulation: PTFE is used as wire insulation in the automotive industry due to its excellent electrical insulation properties and resistance to temperature extremes.

- Bushings and Bearings: PTFE bushings and bearings are employed in suspension systems and various moving parts to reduce friction and enhance durability.

- Fuel Lines and Hoses: PTFE-lined hoses are used for fuel and oil transport, thanks to their resistance to chemicals and extreme temperatures.

Aerospace Industry

- Aircraft Components: PTFE is used in aircraft components, such as seals, gaskets, and bearings, where high-temperature resistance and reliability are critical.

- Wire and Cable Insulation: PTFE-insulated wires and cables are used in aircraft wiring due to their lightweight, low loss, and resistance to heat.

Healthcare Industry

- Medical Devices: PTFE is employed in medical devices and equipment due to its biocompatibility, low friction, and resistance to sterilization processes.

- Laboratory Equipment: PTFE-coated laboratory glassware and containers prevent chemicals from sticking, facilitating easy cleaning and handling.

Cookware and Food Processing

- Non-Stick Cookware: PTFE coatings on cookware prevent food from sticking, reduce the need for oil or butter, and simplify cleaning.

- Food Processing Equipment: PTFE components are used in food processing machinery due to their non-reactive and non-contaminating properties.

Electronics and Telecommunications

- Electrical Insulators: PTFE is used as an electrical insulator in cables, connectors, and circuit boards, ensuring reliable electrical performance.

Construction and Architecture

- Architectural Membranes: PTFE-coated fiberglass membranes are used in architectural applications, such as stadium roofs and large-scale structures, due to their durability and light-transmitting properties.

Other Miscellaneous Applications

- Seals and O-rings: PTFE seals and O-rings are employed in various industries for their chemical resistance and sealing capabilities.

- Lubricants: PTFE-based lubricants provide long-lasting, low-friction lubrication in automotive and industrial applications.

5. Advantages and Limitations of PTFE

Advantages

- Chemical Inertness: PTFE is highly resistant to chemical attack, making it suitable for handling corrosive substances.

- Temperature Resistance: It can withstand a wide temperature range, from -200°C to 260°C (-328°F to 500°F) without losing its properties.

- Low Friction: PTFE’s low friction coefficient reduces wear and energy consumption in moving parts.

- Non-Stick: Its non-stick nature simplifies cleaning and prevents materials from adhering to surfaces.

- Electrical Insulation: PTFE is an excellent electrical insulator, ensuring reliable performance in electrical applications.

Limitations

- Cost: PTFE can be relatively expensive compared to some other polymers.

- Not Suitable for High Load Applications: In high-load applications, PTFE may experience deformation or creep.

- Not Biodegradable: PTFE is not biodegradable, and its disposal can raise environmental concerns.

6. Challenges and Environmental Considerations

Environmental Impact

While PTFE offers numerous advantages, its environmental impact has raised concerns. PTFE is non-biodegradable and does not break down naturally in the environment. Additionally, the production of PTFE can involve the use of perfluorooctanoic acid (PFOA), a chemical compound that has environmental and health concerns associated with it. Efforts are being made to reduce the environmental footprint of PTFE production and disposal.

Recycling and Sustainability

Recycling PTFE has proven to be a challenging task due to its inert nature. However, some companies have developed methods for recycling PTFE waste and reusing it in various applications. Sustainable practices in PTFE production, such as reducing emissions and minimizing waste, are also being adopted to mitigate its environmental impact.

7. Future Trends and Developments

Emerging Applications

PTFE continues to find new applications across industries. Emerging trends include the use of PTFE in advanced materials, such as nanocomposites and coatings, to enhance specific properties like self-cleaning and anti-microbial properties. PTFE is also being explored for use in 3D printing applications.

Advances in Manufacturing Techniques

Advanced manufacturing techniques, such as additive manufacturing (3D printing), are being employed to create complex PTFE components with precision. These techniques offer new possibilities for custom-designed parts with optimized performance.

Sustainable PTFE

Research and development efforts are ongoing to develop more sustainable forms of PTFE, including alternatives to PFOA in the production process and improved recycling methods. These initiatives aim to reduce the environmental impact of PTFE and enhance its sustainability.

8. Conclusion

Polytetrafluoroethylene (PTFE) has had a profound impact on various industries due to its exceptional properties and versatility. From non-stick cookware to critical aerospace components, PTFE has become an indispensable material in modern manufacturing. While it offers numerous advantages, efforts are ongoing to address environmental concerns associated with its production and disposal. As technology advances and sustainability becomes a greater focus, PTFE is likely to continue evolving, finding new applications and minimizing its environmental footprint. With its remarkable properties and ongoing innovations, PTFE remains a vital material in the world of polymers, enhancing products and processes across the globe.

FAQs about PTFE