What is Surge Control in Compressor

Since the fundamental purpose of any compressor control is to prevent or limit the effects of surge, it is appropriate to review the phenomenon itself. Surge occurs when the low flow operation limit of a compressor has been exceeded, resulting in flow reversal.

It is an unstable, pulsating condition that is usually evident by an audible boom, piping vibration, rapid increase in discharge temperature and oscillation of flow and discharge pressure. Violent surging may cause the following compressor damage:

Damage Possibilities in Compressor

• Open internal clearances which damage impeller seals and balance piston seals.

• Damage the compressor shaft end seals.

• Damage the compressor thrust bearings.

• Damage the compressor radial bearings.

• Cause impellers to rub against stationary diaphragm.

• Cause a shaft coupling failure.

• Possible shearing of drive shaft.

Along with compressor damage, the process flow and pressure can become very unstable contributing to upstream and downstream process upsets.

Principle operation of Compressor with Antisurge Concept

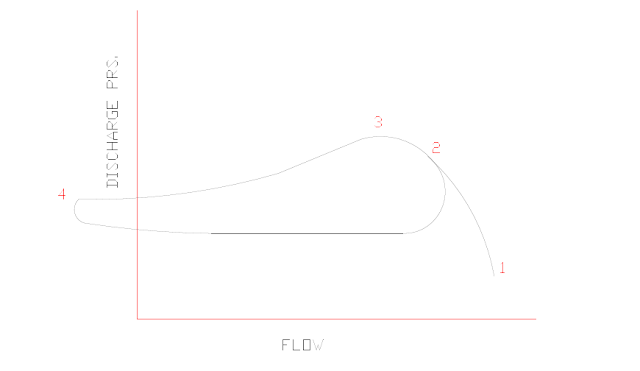

Figure shows a simple surge cycle at a constant speed and constant suction pressure. The compressor, operating at point 1, has low discharge pressure and the output flow is at its maximum value. As the system resistance increases (e.g. discharge valve closes, downstream processes shutdown or decrease load, series units drop off-line, or parallel units come on-line), the compressor flow decreases, and discharge pressure increases.

At operating point 2, the compressor is near the surge limit. As the system resistance increases further, the flow continues to decrease, and discharge pressure continues to increase. Eventually, a limit is reached where the compressor can no longer increase discharge pressure, such as at operating point 3.

If the system resistance increases further, the discharge pressure becomes greater than the machine’s capability. This initiates a surge that spans between points 3 and 4. Flow may actually reverse through the compressor, as shown at point 4.

A now reduced system resistance will allow increased flow back through the compressor that brings the operation back to point 2. This surge cycle will continue until broken by some control or operator action.

Maintaining flow above the compressor’s surge limit prevents these surge conditions. The controller must continually monitor the operating point and compare it to the surge limit of the compressor. If the operating point reaches a minimum flow value, the controller responds by opening the anti-surge valve(s). This simultaneously causes the flow to increase and discharge pressure and polytropic head to decrease, moving the operating point away from the surge limit.