- PURPOSE

- SCOPE

- REFERENCES

- EQUIPMENT & TOOLS

- METHODS / PROCEDURE

- RESPONSIBILITIES

- ATTACHMENT

1.0 PURPOSE

This Procedure or Method Statement shall provide minimum guidelines to carry out the tightening of high strength bolted connections for Structural steel.

2.0 SCOPE

The scope covers tightening of high strength bolted connections for structural steel as defined in the scope of work of this project.

3.0 REFERENCES

SAES-M-100 – Saudi Aramco Building Code

SATIP-M-001-01 – Structural Steel Piperack, Steel Supports & Miscellaneous Steel Structures (including Pipe Supports per Specification)

SAIC-M-2021 – Receiving Inspection – Bolts, Nuts & Washers for Structural Connections

SAIC-M-2009 – High Strength Bolt Tightening Inspection and Testing

SATR-M-2003 – Pre-Installation Procedure Verification Testing of Direct Tensioning Indicator

SATR-M-2004 – Pre-Installation Procedure Verification Testing of Calibration Wrench

Project scope of work

Approved Construction Drawings

4.0 EQUIPMENT and TOOLS

4.1. Torque Wrench

4.2. Electric Impact Wrench

4.3. Air Impact Wrench

5.0 Method / Procedure Tightening of High Strength Bolted Connections

5.1. Material Receiving Inspection

a. Bolting materials shall be thoroughly checked by QC Inspector to ensure that the correct bolt types and sizes match with the IFC drawing and applicable code and standards.

b. All bolt, washers & nuts shall be packed & delivered in rigid weather proof container, cardboard containers are not acceptable.

c. A shipping list (including total weight) a bolt list & a minimum of two sets of final drawings shall accompany the shipment as per 12-SAMSS-07 para.6.5.1.

d. All High strength Bolts shall conform to ASTM A325/A325M or A490/A490M, washer shall conform to ASTM F463/F463M and Heavy Hex. Nuts shall conform to ASTM A563/A563M.

e. All bolts, nuts & washers shall be identified with material grade, all unknown fasteners are prohibited.

f. A minimum of 5% extra quantities of each bolt size & length, nuts & washer shall be furnished by contractor.

g. Mechanically galvanized bolts and nuts shall not be intermixed with those of hot-dip galvanized.

5.2. Bolt Tightening Requirements

a. QC Structural Inspector shall check and verify the correct bolts and ensuring that all inspections and requirements is carried out in accordance with project drawings specification, He shall signify his acceptance on the reports.

b. Check all the members of the structure to be connected with bolt. Check bolt hole dimension and location.

c. Clean the surface of all bolted connections. Ensuring item shall be free from any loose mill scale, dust, oil and other contaminants.

d. No permanent bolting shall be carried out unless the final location and alignment has been obtained and verified.

e. The structure shall be plumbed, leveled, and braced before any final bolted or welded connections are made. (PIP STS05130, Erection of structural and Miscellaneous Steel Specification, Sec.6.3.2)

f. ASTM A325 N Bolts are used for primary structural connections.

g. Minimum size for ASTM A325 N Bolts shall be 20mm in diameter.

h. Anchor bolts shall be fully tightened only after the base plates have been grouted (PIP STS05130, Erection of structural and Miscellaneous steel specification,Sec.6.4.3).

i. Prior to bolt tightening the QC Structural Inspector shall check the calibration certificates of all the torque wrenches & prepare the torque record as per the SATIP-M-001-01.

j. Fit-up bolts & drift pin shall not be used to bring fabricated members & parts in to place (springing). Drift pins shall not be driven with such force as to damage adjacent metal areas.

k. When approved by the engineer of record , the erector may enlarge standards holes by 1/16inch (1mm) when necessary to make connections resulting from minor misfit. Holes in connection that misfit by more than 1/16inch (1mm) shall be corrected as directed by the engineer of record.

l. Enlargement of holes shall be made by reaming or drilling only. Flame cutting, burning gouging, chipping or drift punching shall not be permitted.

m. No packing, shimming, filling or wedging shall be permitted to correct faulty works unless approved by the Engineer of record.

n. One filler plate up to 1/8inch (3mm) thickness may be used as required in spaces between members to be bolted. The engineer of records approval shall be required for filler plate requirements greater than 1/8inch (3mm).

o. Prior to intial snug tightening all connections and their components shall be checked against the IFC Drawings and Specifications. (AISC, Specification for structural joints using ASTM A325 or A490 Bolts,Sec.9.1)

p. After the connections have been asembled, it shall be ensured that the ply of the connected elements have been brought in to firm contact and washers have been used as required(AISC, Specification for structural joints using ASTM A325 or A490 Bolts,Sec.9.1).

q. During assembling on the ground, for main frame, Fully Tightening Condition shall be applied, and QC Structural Inspector will check using calibrated torque wrench.

r. For secondary member of structure that installed at the elevated place for connection to the main frame, temporary Tight Condition shall be applied before Fully Tightening Condition.

5.3. Bolt Tightening Methods

5.3.1 Snug Tightening

5.3.1.1 All bolt holes shall be aligned to permit insertion of the bolts without undue damages to threads.

5.3.1.2 Bolts shall be placed in all holes with washers positioned as required and threaded nuts to complete the assembly .

5.3.1.3 Compacting the joint to the snug tight condition shall progress systematically from the most rigid part of the joint.

5.3.1.4 The snug tightening condition is the tightness that is attained with a few impacts of an impact wrench or the full effort of an iron worker using an ordinary spud wrench to bring the connected

plies in to firm contact.

5.3.2 Calibrated wrench method

5.3.2.1 All torque wrenches shall be calibrated prior to use and shall be re-calibrated every twelve months.

5.3.2.2 A calibrated tension calibrator shall be on site when tightening is to be performed on pre-tensioned joints and slip-critical joints.

5.3.2.3 Prior to application, the bolted joint assembly shall be brought to snug tight condition. NOTE : The connected piles are in firm contact after using a few impacts of an impact wrench or the full effort

of an iron worker using an ordinary spud wrench (PIP STS05130, para. 6.5.1 &AISC Spec for structural joints using ASTM A325 or A490 Bolts, Para.8.2.1).

5.3.2.4 A representative sample of three complete fastener assemblies of each combinaton of diameter, length, grade and lot to be used in the work shall be checked at the site of installation using a tension calibrator.(PIP STS05130,Para.6.5.1 & AISC Specification for structural joints using ASTM A325 or A490 Bolts, Para 3.2.1).

5.3.2.5 An ASTM F436 washer shall be used under the turned element.(PIP STS05130, Para.6.5.1 & AISC Spec for Structural joints using ASTM A325 or A490 Bolts, Para.6.2.2).

5.3.2.6 The pre-installation verification procedure testing is performed using fastener assemblies that are representative of the condtion of those that will be pre-tensioned in the work. (PIP STS05130, para. 6.5.1 &AISC Spec for structural joints using ASTM A325 or A490 Bolts, Para.8.2).

5.3.2.7 The test is performed to verifiy that the pre tensioning method develop a pretension that is equal to or greater than 1.05 times that specified for installation and inspection in table 8.1 in attachement 1 of this check list.(PIP STS5130,para 6.5.1 & AISC Specification for Structural joints using ASTM A325 or A490 Bolts para 7.2).

5.3.2.8 If the actual pretension developed in any fastener assemblies is less than 1.05 times that specified for the installation and inspection in table 8.1 in attachment 1 of this check list , the causes shall

be determined and resolved before the fastner assemblies are used in the work .( PIP STS5130,para 6.5.1 & AISC Specification for Structural joints using ASTM A325 or A490 Bolts para 7.2).

5.3.2.9 The erector shall mark the ends of the torque bolts whenever it is properly tensioned and ready for inspection.

5.3.3 Direct Tension Calibrator

5.3.3.1 Direct tension indicator have been inspected & verified to meet the material requirements of ASTM F959 through checklist SAIC-M-2021(PIP STS5130 para 6.5.2).

5.3.3.2 A calibrated tension calibrator shall be on site when tightening is to be performed on pretensioned joints and slip-critical joints. (PIP STS5130,para 6.5.2 & AISC Specification for Structural joints using ASTM A325 or A490 Bolts para 8.2.4).

5.3.3.3 A representative sample of three complete fastener assemblies of each combination of diameter, length, grade and lot to be used in the work shall be checked at the site of installation in a tension calibrator (PIP STS5130, para 6.5.2 & AISC Specification for Structural joints using ASTM A325 or A490 Bolts para 8.2.4).

5.3.3.4 Washers are used in the pre-installation verification assemblies as required in the work .(PIP STS05130, para. 6.5.2 &AISC Spec for structural joints using ASTM A325 or A490 Bolts, Para.8.2.4).

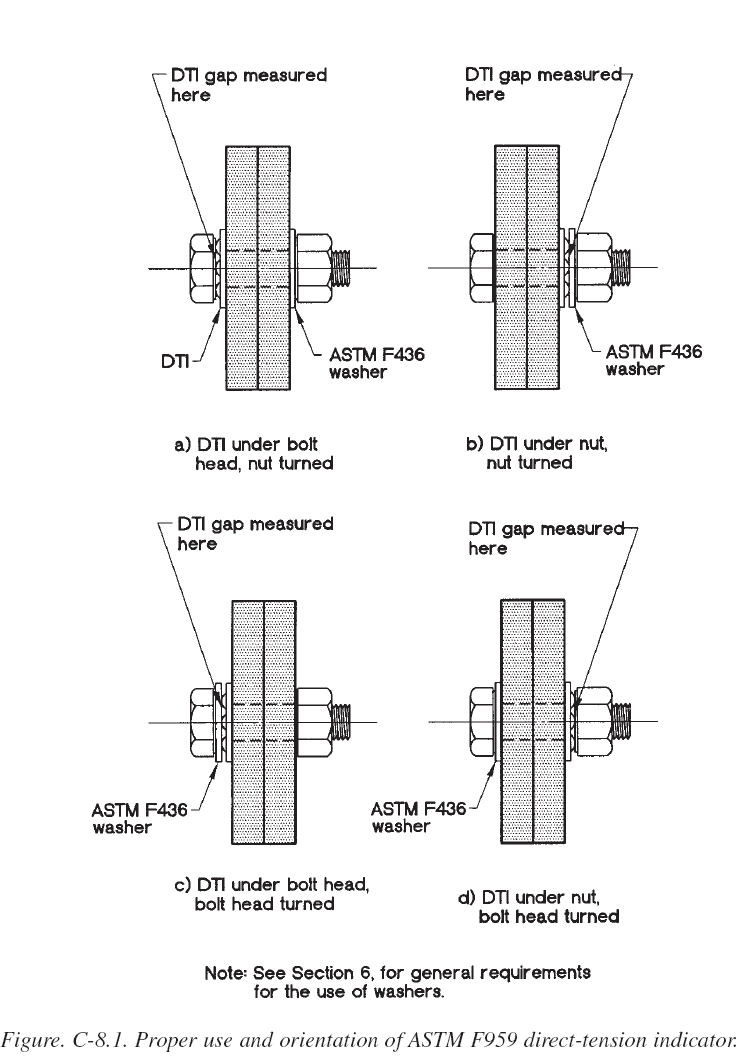

5.3.3.5 The direct tension indicator arches are oriented to bear against the hardened bearing surface of the bolt head or nut or against a hardened flat washer if used under turned element whether that turned element is nut or the bot. Proper use and orientation is illustrated in Table 8.1 Attachement 2. (PIP STS05130, para. 6.5.2 & AISC Spec for structural joints using ASTM A325 or A490 Bolts, Para.8.2.4).

5.3.3.6 Prior to pre-tensioning, the appropriate feeler gauge is accepted in at least half of the spaces between the protrusions of the direct tension indicator. (PIP STS05130, para. 6.5.2 & AISC Specification for structural joints using ASTM A325 or A490 Bolts, Para.9.2.4).

5.3.3.7 The bolt assembly was tightened with the direct tension indicator until a pretension of greater than or equal to 1.5 times that specified for the installation and inspection in Table 8.1 in Attachment 1

of this checklist was reached ( PIP STS05130, para. 6.5.2 & AISC Specification for structural joints using ASTM A325 or A490 Bolts, Para.8.2.4).

5.3.3.8 After pre-tensioning , the appropriate feeler gage is refused entry in to at least half of the spaces between the protrusions (PIP STS05130, para. 6.5.2 & AISC Specification for structural joints using ASTM A325 or A490 Bolts, Para.9.2.4).

5.3.3.9 After passing the feeler gage test , loosened the bolted assembly and examine the DTI and the bearing surface for the following acceptable conditions

a) The protrusions on the DTI were deformed.

b) The bearing surface has no significant depth of indentation or gouge.

(PIP STS05130, para. 6.5.2 & AISC Specification for structural joints using ASTM A325 or A490 Bolts , para 9.2.5).

5.3.3.10 The erector shall colour code , die punch or otherwise mark the ends of the torque bolts indicating that the bolts have been properly tensioned and are ready for inspection.

ATTACHMENT-01

ATTACHMENT-02

5.3.4 Turn of the Nut

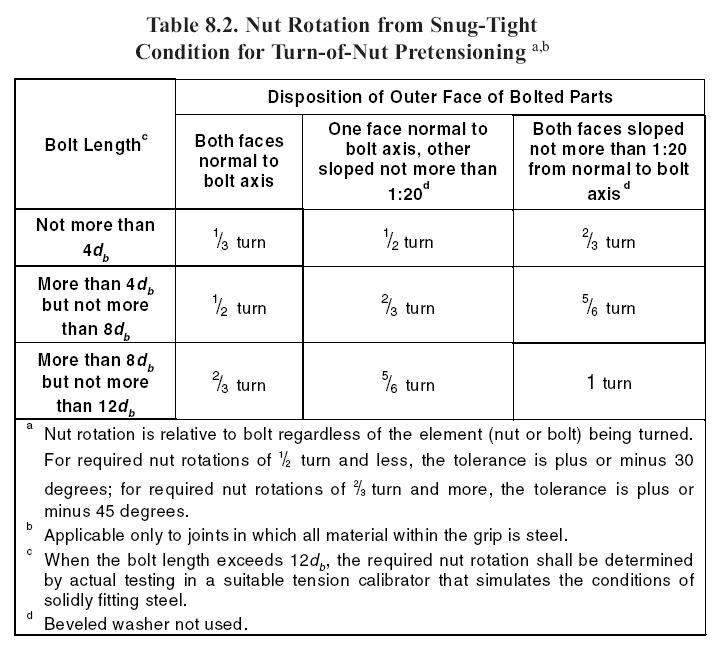

5.3.4.1 All pre-tensioned joints shall be snug tightened first and shall be inspected for the required match marking before and after pre-tensioning as visual proof that the pre-tensioning has been accomplished. Proper nut rotation is illustrated in Table 8.2 (AISC Spec for structural joints using ASTM A325 or A490 Bolts, Para.9.2).

5.3.4.2 When the joints being inspected are Slip-Critical , it is necessary to verify that the faying surfaces meet the requirements as specified in IFC Documents, prior to assembly of the joints (AISC Spec

for structural joints using ASTM A325 or A490 Bolts, Para.9.2).

5.3.4.3 The inspector shall observe (for Turn of the Nut Method) the pre-installation verification testing (minimum of 3 bolts) of each size, type and grade of fasteners (AISC Spec for structural joints using ASTM A325 or A490 Bolts, Para.9.2.1).

5.3.4.4 The inspector shall insure , during routine observation by the bolting crew, that the turned element relative to the unturned element, has moved the amount specified Table 8.2.

5.3.4.5 Structural joints made using high-strength bolt assemblies, the materials, methods of installation, tension control, types of wrenches to be used and inspection methods shall comply to AISC Specification using ASTM A325 or A490 Bolts.

5.3.4.6 Upon identification of the types of bolts to be use and alignment of the members of the structure, proceed with the bolting work.

5.3.4.7 For bearing type connection, bolt torque shall be done in two stages.First , is the initial torque value achieved with impact wrench and then the final torque value achieved with torque wrench(Tightening torques refer to Table-1).

5.3.4.8 For the pretension joints or the slip-critical joints, the installation torque determined from the preinstallation verification (AISC-Section 7) shall be applied to all bolts in the joints. The pre-installation verification shall be performed daily.

5.3.4.9 The erection supevisor shall select one(1) access method, how can erector access to portion of connections for erection and bolting. There are three (3) access methods to be used, the temporary platform, man-basket and man-lift car. Also, scaffolding pipe instead of life rope located at span of column to column which is used for hanging of erector’s harness.

5.3.4.10 The erector shall color code, die punch or otherwise mark the ends of the torque bolts indicating that the bolts have been properly tensioned and are ready for inspection.

6. RESPONSIBILITIES

6.1 Erector shall maintain the job site in a clean & safe condition at all times and properly dispose off, all crating, waste materials and other refuse that has accumulated as a result of the erectors activities under this practice.

6.2 Erector shall keep a daily record by piece number of all materials erected, He shall check foundations and other connection points to confirm their location, orientation, elevation, and condition.

6.3 QC Structural Inspector shall check and verify the correct bolts and ensuring that all inspection requirements are carried out in accordance with project drawings specifications.

6.4 Site Manager shall be responsible in providing all necessary requirements at site such as safety ppe, manpower, materials and equipment to carry out the bolt tightening activity as per schedule

and as per project specification.

6.5 Safety Officer shall be responsible in carrying out safety measures such as preparation of barricades and warning signs, work permits, etc.