1.0 PURPOSE

2.0 SCOPE

3.0 APPLICABLE DOCUMENTS

4.0 RESPONSIBILITY

5.0 MANPOWER

6.0 TOOLS & EQUIPMENT

7.0 METHODS/PROCEDURES

8.0 QUALITY CONTROL

9.0 SAFETY PRECAUTION

10.0 ATTACHMENTS.

METHOD STATEMENT INSTALLATION OF FURNACE AIR PRE HEATER

1.0 PURPOSE:

This method statement shall provide minimum guidelines in accordance with Saudi Aramco project drawings and specification to erect APH in plants and refinery projects.

2.0 SCOPE:

This specification covers the minimum requirements for erection of Air Pre Heater to be applied in plants and refinery projects.

3.0 APPLICABLE DOCUMENTS:

3.1 Specification and Standards

3.1.1 S-000-1630-003 Material and Equipment Protection Program at work Site.

3.1 .2 S-000-1520-103 Handling Procedure.

3.1.3 S-000-1640-005 Procedure for Work Release Between Disciplines.

3.1.4 $-000-1520-102 Non-Conformity Control Procedure.

3.1.5 $-000-1520-101 Field QC Procedure.

3.1.6 S-000-1650-001 Safety Execution plan.

3.17 $-000-1351-002 Installation Marking Procedure.

3.1.8 S0003150-001 Installation of Static Equipment.

3.1.9 FWBS CODE (5000) Equipment Installation.

3.2 ARAMCO Project Specifications and Standard

3.2.1 SAES-F-001 Design Criteria of Fired Heaters.

3.2.2 SAES-H-001 Coating Selection and Application Requirements for Industrial Plants and Equipment.

3.2.3 32-SAMSS-029 Manufacture of Fired Heaters.

3.2.4 SAEP-302 Instruction for obtaining a waiver of a mandatory Saudi ARAMCO Engineering requirement.

Related Vendors Installation and maintenance manuals and /or specifications.

3.2.5 SAES-Q-005 Concrete foundation.

3.2.7 SAES-Q-010 Cement Based Non-shrink Grout for Structural and Equipment Grouting.

3.2.8 SAES-H-101V Approved Saudi Aramco Data Sheets – Paints and Coatings.

3.3 Industry Codes and Standards:

3.3.1 AWS D1.1 Structural Welding Codes

3.4 Inspection and Testing Plan/Method Statement

3.4.1 SATIP-D-001-01 Typical Inspection Plan Pressure Vessel Installation

34.2 SATIP-Q-010-01 Cement Based Non-Shrink Grouting

3.4.3 SATIP-M-001-01 Structural Steel-Piperack, Steel Supports & Miscellaneous* Steel Structures (* Incl. Piping Supports per Specification)

3.4.4 SATIP-F-001-01 Fired Heaters – Field Installation

34.5 SAIC-F-2004 Receiving Inspection of Fired Heaters & Components

3.4.6 SAIC-F-2004 Handling, Storage and Preservation of Fired Heaters

3.4. 7 SAIC-F-2006 Fired Heaters – Field Installation

3.4.8 SAIC-F-2008 Final lnsp of Fired Heater & Components (Re-Instatement)

3.5 Latest Revision of the following Documents shall be used.

3.5.1 Vendor Drawing.

3.5.2 Foundation Drawing.

3.5.3 Equipment Details.

3.6 Saudi ARAMCO Safety, Health and Environmental Standard:

3.6.1 Construction safety manual – compliance with schedule D.

3.6.2 General Instructions (G.l’s) at the work site.

4.0 RESPONSIBILITY:

4.1 Construction Manager shall be responsible for implementing HSE, analyze and schedule all construction activities with his department to include manpower and equipment line up as well as other possible resources required for the successful implementation of the construction work activities. Study all aspects of work procedure as per Saudi Aramco Standards.

4.2 Mechanical Superintendent/ Supervisor shall study and review all necessary documents for the Erection works in his area to

include, technical scope of work, specification, bill of quantities, planned milestone dates and construction procedure in support to his Mechanical Foreman. He shall monitor the availability of materials in accordance with the schedules and construction analysis. He shall be directly reporting to the Construction Manager. He shall coordinate with other discipline to visualize possible conflicts in the drawings as well as in the schedules to provide other options in preventing unnecessary delays and obstructions.

4.3 The Welding Supervisor and/or Foreman are solely responsible to ensure that all welding works are in conformance with applicable codes, standards, specifications and approved procedures.

4.4 Mechanical Foreman shall be responsible for the direct work supervision at site and ensured that the work is performed in accordance with Saudi Aramco Standards and latest approved for construction drawings. He shall monitor the availability of materials in line with his required schedule.

4.5 QC Inspector shall be responsible in monitoring and inspection of the work and ensured that the work is performed and properly documented in accordance with Saudi Aramco Standards.

4.6 Safety Officer/Supervisor shall be responsible in monitoring safety aspects and ensuring that the work is done in accordance with Saudi Aramco Safety Standard.

Procedure He shall discuss to the workers the characteristics of related materials and Status of work area giving reminders as an additional point to work safely.

5.0 MANPOWER

5.1 The Mechanical Supervisor shall control the overall activity. The basic manpower under him shall consist but not limited to the following:

5.1.1 Supervisor Mechanical

5.1.2 Foreman mechanical

5.1.3 Rigger ( certified)

5.1.4 Welder

5.1.5 Mechanical Fitter

5.1.6 Masons/Carpenters

5.1.7 Crane Operator (certified)

5.1.8 Safety Engineer/supervisor

5.1.9 Truck driver

5 1.10 QC Inspector

5.1.11 Surveyor

5.1 12 Helper/ Fire watcher

5.1.13 Structural Worker

6.0 TOOLS AND EQUIPMENT;

6.1T00ls and equipment needed should be in good condition and must be checked by Mechanical Supervisor/Safety Officer prior to use

in the construction area. These Includes but not limited to:

6.1.1 Calibrated engineering level with calibration certificate

6.1.2 Corrective wrenches all required range

6.1.3 Certified sling and hoists

6.1.4 Rigging accessories

6.1.5 Theodolite

6.1.6 Auto level

6.1.7 Crane

6.1.8 Welding Machine

7.0 METHODS/ PROCEDURES:

7.1 Jobsite Receiving and Inspection:

7.1.1 Upon withdrawal and receipt of equipment from warehouse, receiving inspection shall be conducted immediately to verify compliance with the latest revision of vendors drawing, project requirements & SAEP-302.

7.1.2 Record of Material Receiving

Inspection shall be documented. Findings, deviations shall be documented in Quality control Inspection Report (QCIR) and Non Conformance Report (NCR).

7.2 Equipment Preservation/Protection:

7.2.1 Vendor’s/Manufacturer’s recommendation for equipment preservation shall be followed, also comply with project requirements and standard.

7.3 Preparatory Works:

7.3.1 Secure work permit prior to work commence.

7.3.2 Tools and equipment shall be made operational and available for use. Ensure tools are color-coded accordingly. Calibration certification where required shall be in valid dates.

7.3.3 Mobilize all manpower, tools and equipment needed for the job.

7.3.4 Check the availability of material according to the erection sequence.

7.3.5 Install barricades to confine the area for authorized personnel only.

7.4 Foundation Preparation for APH:

7.4.1 Confirm acceptances & turnover of civil works foundation/pedestals with a signed copy of works release notice prior to installation of equipment / structure.

7.4.2 Verify the equipment seating area requirements.

7.4.3 When the foundation released the following points shall be checked with the latest relevant drawing:

7.4.3.1 Distinct position (centre) marking and height (level) marking on the foundation, It will be referred for alignment work of level and position.

7.4.3.2 Size and number of anchor bolt and nuts, position of anchor bolts with projection

7.4.3.3 Existence of damages and rust of threaded of buried anchor bolts with projection.

7.4.3.4 Trace centerlines of foundation bolt holes with reference to grid lines. Check Verticality/plumbness of anchor bolt.

7.4.3.5 Clean the surface thoroughly by blowing with oil-free from air compressor.

7.4.3.6 Centerlines lost due to chipping operations will retrace anew.

7.44 Anchor bolts shall be protected properly to avoid damages during chipping/padding work and keep it up to the structure & equipment installation.

7.4.5 The elevation of the chipped top foundations shall be set to consider the required grout thickness under the base plate as per the design drawings.

74.6 The bottom of the bases shall be cleaned and free of laitance, oil or grease.

7.4.7 Laitance shall be removed from the surface of the foundation and boxes by chipping to ensure good adherences of padding and grout materials to the surface preparation.

7.5Dimensional Inspection and Checking of Foundation:

7.5.1 Using Work Transfer Sheet, following shall be done:

7.5.1.1 Establish centerlines (Northing and Easting) of columns reference to applicable foundation/civil drawings.

7.5.1.2 Using an auto level, confirm Top of Concrete (T.O.C.) elevation.

7.5.1.3 Compare data with reference drawings and Survey Data Record. Note the discrepancies and unacceptable tolerances and report through QCIR

75.2 Pads material shall be in accordance with ASTM A283 Gr.C, Dor equivalent

75.3 Pad shall be hot dip galvanized in accordance with ASTM A123 or coated with zinc rich epoxy primer in APCS-1C of SAES-H-101/ as applicable

7.5.4 In general, the distance between pads shall not exceed 800mm. If the distance becomes more than 800mm, an additional pad shall be added in between.

7.5.5 Pad size shall be selected as per the anchor bolt size as follows:

7.5.5.1 Bolt diameter M24 or 1 inch and below: Pad width 50mm width.

75.5.2 Bolt diameter M30-M48 or 1-1/4 to 2 inches: Pad width 75mm.

7.5.5.3 Bolts diameter M56 or 2-1/4 inches and above Pad width 100mm.

7.5.6 Number of pads shall be determined so the load pressure will be less than 30kg/cm?. The supporting load can be calculated as per following formula.

L=W/NxAxB

L: Load supported by liner (kg/cm2)

W Lifting load of equipment (kg)

N: Number of pads

A: Width of base plate for equipment (cm)

B Width of liner (cm)

7.5.7 The length of pad shall be 20 mm to 30 mm longer than the width of the equipment bases.

7.5.8 After finishing padding work, following points shall be checked

7.5.8.1 Position of center and elevation line of foundation

7.5.8.2 Elevation and position of pads

7.5.8.3 Cleanliness of concrete surface

7.5.8.4 Condition of anchor bolts

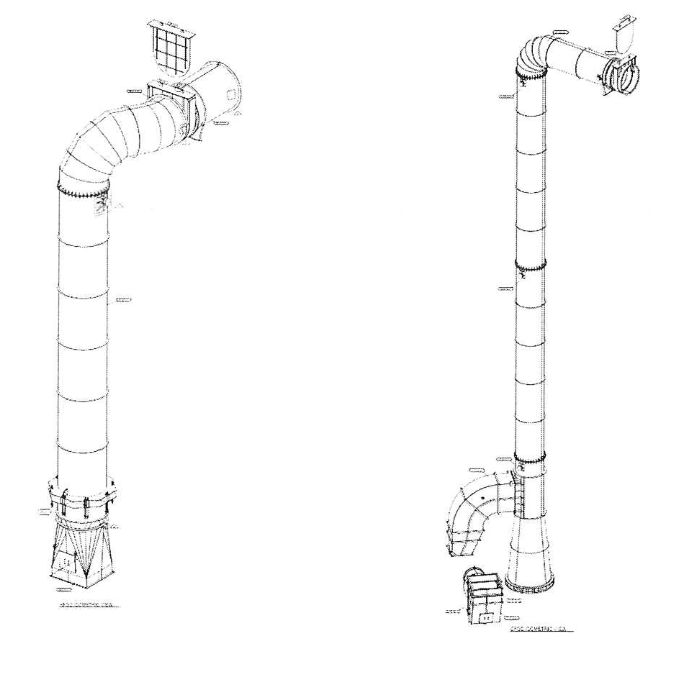

7.6 Erection of APH

7.6.1 Prepare lifting location where the crane will be located and positioned.

7.6.2 Prepare and set all rigging accessories according to arrangement.

7.6.3 Checked wind condition, lift shall not proceed when wind velocity is greater than required of crane.

7.6.4 Stabilized ground areas where crane will be located and positioned. Crane mats shall be provided in accordance to findings of soil bearing pressure.

7.6.5 Make sure that all rigging plans (critical lift if necessary) are approved prior to erect APH and APH structure.

7.6.6 Prior to erect APH structure, verify if orientation and elevation of APH foundation is correct.

7.6.7 Assemble APH structure at ground

7.6.8 Erect APH structure assembly

7.6.9 Place APH materials near the erection location for assembly

7.6.10 Lift vertically with using lifting lug.

7.6.11 See vendor’s erection sequence. (Attachment C)

• V-2156-001-A-814 Installation Manual

• V-2156-001-4A-324 General Arrangement

7.7 Plumb-ness check

• Take sight on the reference point at the top.

• Close the horizontal adjustment knob to lock line of sight of equipment against horizontal movement.

• Take sight on the reference point on the bottom.

• Out-of-plumb dimension from the reference point at the bottom can be measured from the reference point to the survey instrument line off sight using steel tape/measuring stick.

7.7.1 Use steel shims if needed to adjust verticality and plumbness

7.7.2 Shims used for level alignment shall be:

7.7.2.1 Less than 0.0110(2.5 mm) thick shall be stainless steel.

7.7.2.2 Shim thicker than 0.100(2.5 mm) shall be carbon steel.

7.8 After alignment, levelness and final bolt tightening of APH and APH duct shall be completed first before grout setting

7.9 Setting and Alignment

7.9.1 Check elevation, levelness, square-ness and plumb-ness as per Saudi Aramco standard.

7.10 Bolt Tightening

7.10.1 All bolts shall be aligned to permit insertion of bolts without undue damage to the threads.

7.10.2 Any abnormal wear on the equipment and parts during installation and assembly shall be corrected. Prior to the commencement action written work procedure shall be approve by contractor/company.

7.11 Grouting:

7.11 1 Water for mixing grout non-shrink material must be fresh and clean, and free from Injurious of oil acid alkali, salt or organic as per SAES-Q-010 Cement Based, Non-Shrink Grout for structural and Equipment Grouting.

7.11.2 This grout shall meet the requirement of STS 03600 when used in high fluidity range. Compressive strength shall be in excess of 34.5 Mpa (5000 psi) when mixed according to manufacturer instructions.

7.11.3 Grout shall be mixed in accordance’s with grout manufacture’s instruction Sub-con shall prepare sufficient quality of grouting material, clean tools and equipment and suitable water mixture at site to complete the job.

7.12 Alignment Tolerances

7.12.1 Vertical Tolerance

7.12.1.1 The angular variation of the working line from a plumb line shall be equal to or less than 1/500 of distance between working points. AISC Code of Std Practice – Steel Bldgs & Bridges Para. 7.13.1.1 & PIP STS0 5130, Para. 6.2.1.

7.12.2 Plumb-ness tolerance for APH and APH duct shall be max of 25mm per 15m as per API 560 4″ edition, Aug 2007.

7.12.3 Position ±3mm

7.12.3.1 Every 90 degree orientation of base plate shall be measured with reference to the Orientation of the foundation.

7.12.4 Elevation ±3mm

7.12.4.1 The bottom of base plate shall measure with reference to the level marking of the foundation. At least, one point of the base plate shall be aligned within these tolerances.

7.13 Damages and Nonconformity

7 .13.1 Any damages and defects and nonconformity found at site and lay down yard shall be reported immediately

8.0 QUALITY CONTROL

8.1 Sub-con QC Personnel shall be assigned to ensure the quality control and assurance requirement of the project.

8.2 Sub-con QC Personnel well coordinate with inspector to conduct inspection as required.

8.3 Sub-con QC Inspector shall be responsible to conduct all required inspection/documentations and to ensure that all applicable requirements, codes, and standards are complied with SAIC/SATIP.

8.4 Contractor has to utilize the applicable SAIC for every activity.

9.0 SAFETY PRECAUTION:

Obtain the approval of the work permit from the concerned JGC/DAEWOO Representative before starting any work.

9.1 TSTI to conduct daily prior to execution of work.

9.2 Fire Watcher with Fire Extinguisher shall be at work area whenever there is hot work.

9.3 Work execution shall be carried out in accordance with method statement. And in compliance with Saudi ARAMCO General Instruction G.1.7.028, Crane Lifts; Types and Procedure

9.4 Ensure lifting operation complies with GI 7.028. Whenever, critical lifts involved, Rigging Plan shall be prepared and approved by Rigger I.

9.5 Continuous monitoring and inspection shall be implemented to detect and correct

unsafe practices while performing the work activities.

9.6 Provide warning sign and sufficient barricade on working area and only assigned personnel will be allowed in the area.

9.7 Worker shall wear PPE’s needed for the work.

9.8 Install PWAS on all equipment moving in this activity.

9.9 All rigging equipment shall be in good condition and possess a valuable certificate from authorized certifying and inspection department. In compliance with Saudi ARAMCO General Instruction G.1.7.030 Inspection and Testing Requirements for Elevating/lifting Equipment.

9.10 Man lift users shall be trained and certified to operate and use the equipment.

9.11 Mechanical Supervisor shall monitor the work activities to help and to protect all assigned workers against exposure to safety hazards. He shall ensure that

Personal Protective Equipment (PPE’s) are supplied and used and comply with Saudi Aramco Standards.

9.12 Housekeeping shall be maintained and working area shall be kept in a clean and tidy manner.

9.13 Job Hazard and Risk Assessment (JSA) of this method statement shall be disseminated and explained to workers for safety awareness.

10.0 ATTACHMENT

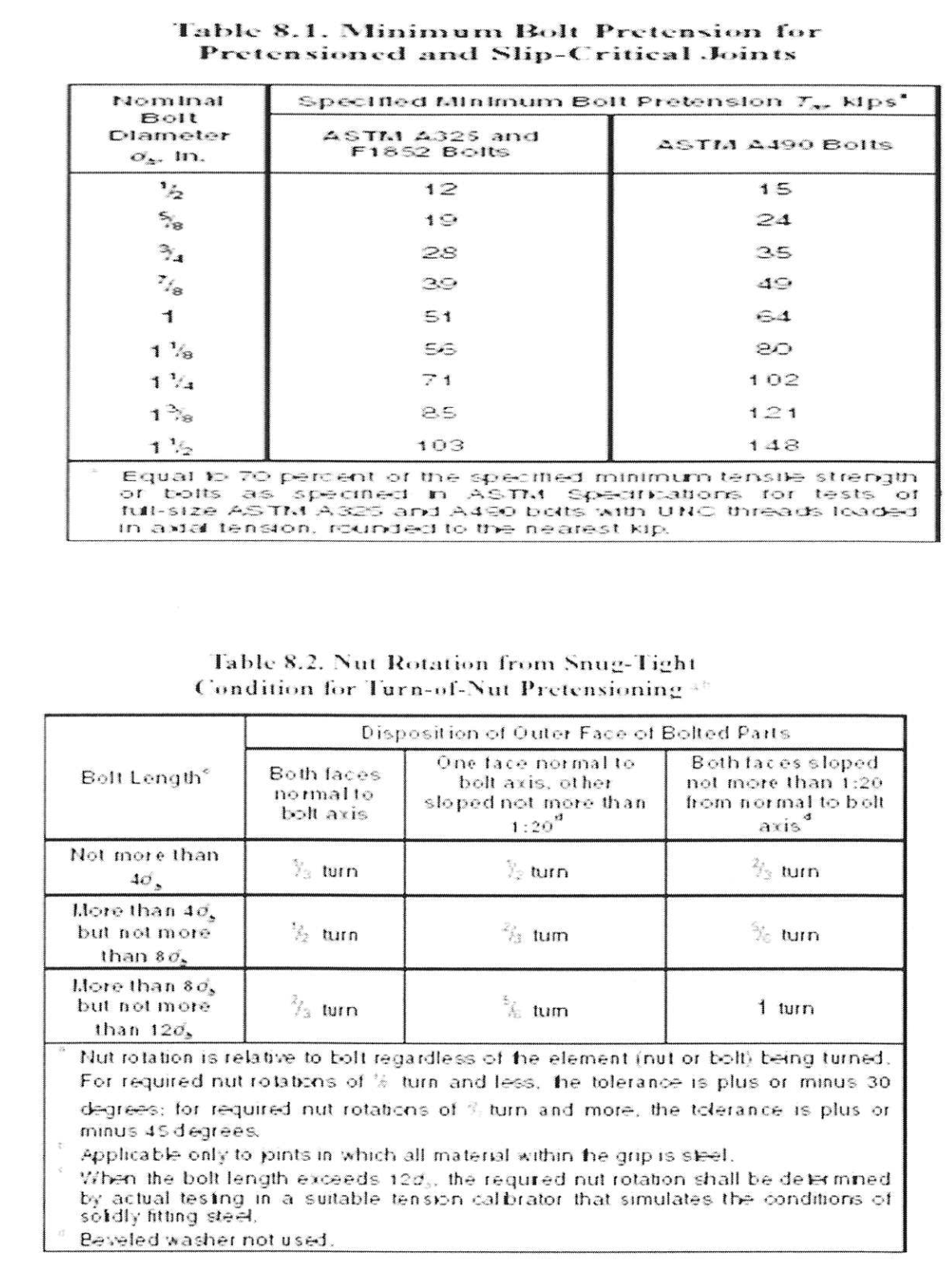

- Structural Bolt Tightening Table.

- Job Safety Analysis (JSA).

- Installation Manual.

- General Arrangement.

Attachment A (Structural Bolt Tightening Table)