Understanding insulation resistance readings is crucial for effective maintenance of electrical equipment. It’s important to note that these readings should be considered relative and can vary even when testing the same equipment repeatedly over a short period. The key focus should be on monitoring the trend in readings over time, as declining resistance values can serve as early indicators of potential issues. To facilitate this process, maintaining records of insulation resistance measurements is highly beneficial, as shown in below Figure.

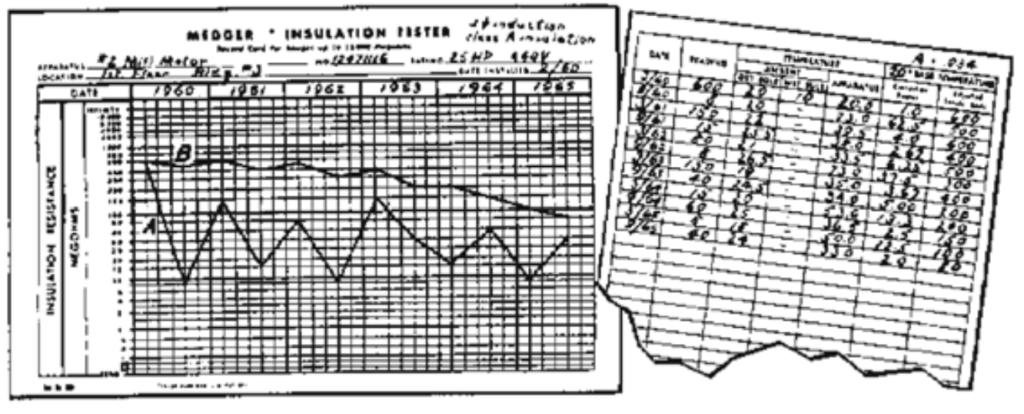

Figure: Typical record of insulation resistance of a mill motor.

In this figure, Curve A represents the test values as measured, while Curve B displays the same values corrected to 20°C (more on temperature correction on page 22). The corrected values in Curve B demonstrate a clear downward trend, indicating a potential unsafe condition in the insulation. The reverse side of the record card (not shown) is used to document the test data.

The frequency of testing—whether monthly, biannually, or annually—depends on factors like equipment type, location, and importance to your plant’s operations. For instance, critical equipment, such as a small pump motor or a control cable integral to a vital process, may necessitate more frequent testing.

Consistency in testing procedures is essential. Perform tests with the same test connections, applying the same test voltage for the same duration each time. Additionally, aim to conduct tests at a consistent temperature or make temperature corrections as needed. Recording the relative humidity near the equipment during testing can also aid in evaluating the readings and trends. Subsequent sections will delve into temperature correction and humidity’s impact on insulation resistance measurements.

In summary, when interpreting periodic insulation resistance tests:

- Focus on the trend in readings over time.

- Maintain comprehensive records of insulation resistance measurements.

- Adjust the testing frequency based on equipment type and significance.

- Ensure consistency in testing procedures, including voltage, duration, and temperature.

- Take note of relative humidity during testing.

- Be prepared to take appropriate action if declining resistance values suggest potential issues.

Certainly, here’s the table with explanations:

| Condition | What to do |

|---|---|

| Good and well maintained | When insulation resistance values are consistently high and the equipment is well-maintained, there is no cause for concern. This indicates that the insulation is in good condition. |

| Good but showing a consistent decline | If the insulation resistance values have been good but are gradually decreasing over time, it’s essential to identify and address the underlying issue causing this decline. This trend suggests a potential problem in the insulation. |

| Low but well maintained | In cases where the insulation resistance values are low but the equipment is well-maintained, it’s crucial to investigate why the values are low. While the equipment might still be safe, the cause of the low values should be examined. |

| Unsafe, very low values | Extremely low insulation resistance values indicate a safety risk. To make the equipment safe for operation, it’s necessary to clean, dry, or take corrective measures to raise the insulation resistance values before use. |

| Sudden drop from previously good values | When insulation resistance values significantly drop from previously stable and good levels, it’s important to conduct frequent tests to pinpoint the issue and take corrective actions promptly. This abrupt decline suggests a potential problem that requires attention. |

Related Articles:

What is Good insulation?

What Makes Insulation Go Bad?

How Insulation Resistance is Measured.

How to Interpret Resistance Readings.

Factors Affecting Insulation Resistance Readings.

Types of Insulation Resistance Tests.

Test Voltage vs. Equipment Rating.

AC Testing vs. DC.

Use of DC Dielectric Test Set.

Tests During Drying out of Equipment.

Effect of Temperature on insulation Resistance.

Effects of humidity.

Preparation of Apparatus to test.

Safety Precautions.

Connections for testing insulation resistance of electrical equipment.

Additional Notes About using A Megger Insulation Tester.

Interpretation-Minimum Values.

Minimum Values for Insulation Resistance.

Tests Using Multi-Voltage Megger Insulation Testers.

Step-Voltage Method.

Use of a Guard Terminal.

Outdoor Oil Circuit Breaker.