Electric motors are crucial components in various industrial applications, and their reliability is paramount to avoid costly breakdowns and ensure safe operations. The aging of mechanical, electrical, and chemical properties within these motors can significantly impact their overall health. One common and fundamental method for evaluating an electric motor’s health is the Polarization Index (P.I.) test. This test provides valuable insights into the insulation condition of electric motors and can help prevent catastrophic failures.

Understanding of Insulation Resistance

Insulation resistance is a critical parameter when assessing the health of an electric motor. It serves as an indicator of the motor’s ability to resist direct current, which is vital for maintaining the integrity of the machine. Low insulation resistance can lead to severe consequences, including damage to electronic driver circuits, such as thyristors, resulting in substantial financial losses due to repairs and replacements.

The Polarization Index Test:

The Polarization Index (P.I.) test is a commonly employed method for assessing the health of an electric motor’s insulation. It is defined as the ratio of the insulation resistance measured at 10 minutes (IR10) to the insulation resistance measured at 1 minute (IR01). Mathematically, this can be expressed as:

P.I. = IR10 / IR01

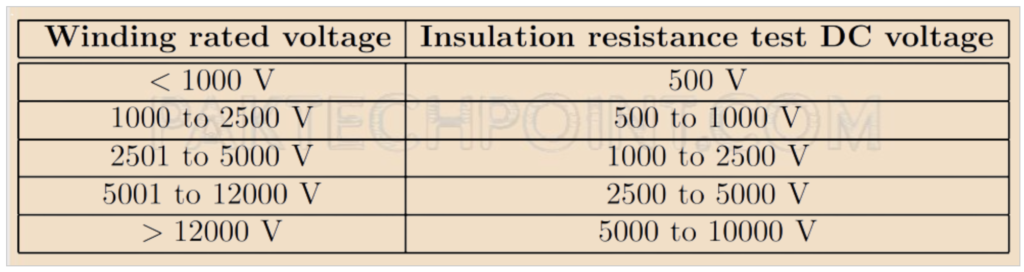

The P.I. test is typically conducted using an appropriate DC step voltage, considering the winding voltage ratings. The IEEE Standard 43-2013 provides recommendations for insulation resistance test DC step voltages, offering a standardized approach to performing this crucial test.

Challenges in P.I. Testing

While the P.I. test is a valuable diagnostic test, several challenges need to be addressed for accurate assessments:

- Time Intervals: Determining the appropriate time intervals for the P.I. test remains a challenge. Different organizations and original equipment manufacturers (OEMs) may have their definitions, leading to inconsistencies in testing procedures.

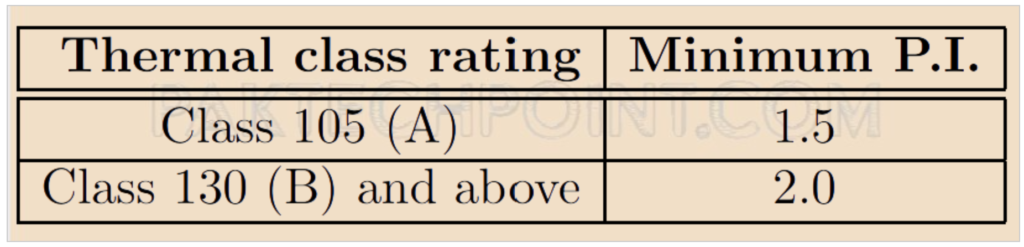

- Minimum P.I. Values: IEEE Standard 43-2013 recommends minimum P.I. values based on the thermal class ratings of insulation. However, these values might not be suitable for modern electric motors with high insulation resistance at 1 minute. In such cases, sensitivity issues related to test equipment, supply voltage, and humidity conditions can compromise the readings.

- Lack of Pass-Fail Criteria: Currently, there are no standardized pass-fail criteria based on P.I. values. Operators often rely on their experience to interpret test results, leading to subjectivity in assessments.

Enhancing P.I. Testing Practices

To address the challenges associated with P.I. testing and ensure more reliable assessments, the following steps can be taken:

- Standardization of Time Intervals: Industry organizations should work towards standardizing time intervals for P.I. tests. This would provide consistency and clarity in testing procedures.

- Revisiting Minimum P.I. Values: For modern electric motors with exceptionally high insulation resistance, revisiting the minimum P.I. values may be necessary. Adjusting these values to align with technological advancements can enhance the effectiveness of the test.

- Establishing Pass-Fail Criteria: Developing pass-fail criteria based on P.I. values can help remove subjectivity from assessments. Clear guidelines for interpreting test results would aid in making informed decisions regarding motor maintenance and repairs.

The Polarization Index (P.I.) test is a valuable tool for evaluating the insulation condition of electric motors. While challenges exist, such as defining time intervals and establishing pass-fail criteria, efforts should be made to standardize and enhance P.I. testing practices. This will ultimately contribute to the reliability and safety of electric motors across various industries, reducing the risk of catastrophic failures and associated financial losses.