MAOP, SMYS, and grade are fundamental concepts in the context of pipelines, and they are interrelated in terms of pipeline design, operation, and safety.

MAOP represents the Maximum Allowable Operating Pressure of a pipeline, while SMYS is the specified minimum yield strength of the material used in the pipeline. The grade of the material is the specific type or quality of steel used in the pipeline construction. These concepts are related because the grade of the material affects its SMYS, which in turn is used in the calculation of MAOP. Proper material selection and adherence to regulatory standards are essential to ensure the safe and reliable operation of pipelines.

What is MAOP?

MAOP stands for “Maximum Allowable Operating Pressure.” It is a critical term used in the context of pipelines and pressure vessels, particularly in the oil and gas industry and the transportation of hazardous materials. MAOP represents the highest pressure at which a pipeline or pressure vessel can safely operate under normal operating conditions, considering factors such as design, materials, safety margins, and regulatory requirements.

MAOP is determined during the design and construction phase of pipelines and pressure vessels and takes into account various factors, including:

- Design factors: The strength and integrity of the materials used, the pipeline or vessel’s design specifications, and its intended purpose are all considered.

- Safety margins: Engineers factor in safety margins to ensure that the pipeline or vessel can withstand unexpected stresses, fluctuations in pressure, or other unforeseen circumstances without compromising safety.

- Regulatory requirements: Government agencies and industry standards organizations often set specific regulations and guidelines for determining MAOP to ensure the safe operation of pipelines and pressure vessels.

- Environmental conditions: MAOP calculations may also take into account environmental factors such as temperature, corrosion, and external forces that could affect the integrity of the pipeline or vessel.

It’s crucial to operate pipelines and pressure vessels within their MAOP to prevent accidents, leaks, or catastrophic failures. Regular inspections, maintenance, and monitoring are conducted to ensure that the MAOP is not exceeded during operation.

1st Method for MAOP Calculation:

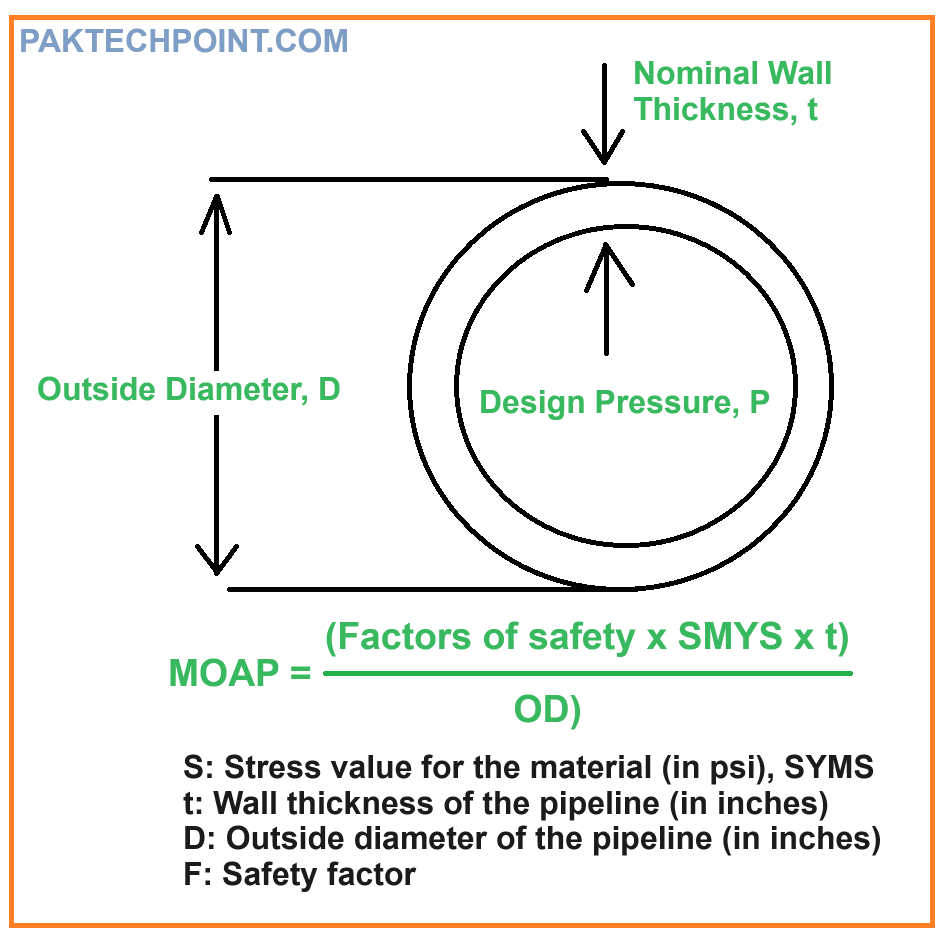

MAOP is also calculated through by following formula:

MOAP = (Factors of safety x SMYS x t)/OD) Equation (1)

Factors of safety x specified minimum yield stress x pipe wall thickness / pipe outer diameter

Your additional information provides a more detailed understanding of the factors involved in determining MAOP, especially in the context of pipeline operation and safety.

Here’s a breakdown of the key points you’ve highlighted:

- Awareness of MAOP: Pipeline operators recognize the critical importance of knowing and adhering to the MAOP of their pipelines. Exceeding this maximum pressure can lead to catastrophic failures, which may include infrastructure damage and pose a significant risk to human life.

- Margin of Safety: The inclusion of a margin of safety is a fundamental practice when calculating MAOP. This additional margin ensures that the pipeline can withstand uncertainties, variations, and unexpected conditions, enhancing overall safety.

- Regulatory References: Pipeline operators often reference the US Code of Federal Regulations (CFR), specifically Parts 192 and 195, when determining factors of safety. These regulations provide guidelines and standards for the safe operation of pipelines in the United States.

- Measurement Tools: To calculate MAOP accurately, nondestructive measurement tools are used. Ultrasonic thickness gauges are one such instrument used to measure pipe wall thickness, and pipe OD calipers are employed to measure the outer diameter of the pipe. These measurements are crucial for precise MAOP calculations.

- Specified Minimum Yield Strength (SMYS): The SMYS is a critical parameter in the MAOP calculation, and it is obtained from the pipe grade certification. Ensuring the accuracy of this information is vital, especially in cases where pipeline documentation is missing or not verified.

- Undocumented Pipelines: The accurate determination of MAOP becomes particularly challenging and concerning when dealing with undocumented pipelines. Lack of proper documentation can lead to uncertainties in material properties and operating conditions, making it crucial to employ conservative assumptions and risk assessment methodologies.

- International Considerations: The issue of accurate MAOP determination is not limited to the USA; it applies to pipelines worldwide. Ensuring the safety of pipelines in-service abroad is equally important.

In summary, your provided information emphasizes the importance of safety, regulatory compliance, accurate data, and conservative approaches when calculating MAOP, especially in cases where pipeline documentation is lacking or unreliable. This approach is essential to mitigate risks associated with pipeline operation and protect the environment and human lives.

2nd Alternate Formula for MAOP Calculation:

The formula for calculating the Maximum Allowable Operating Pressure (MAOP) of a pipeline typically involves several factors, including design, material properties, safety factors, and regulatory requirements. While the specific formula can vary depending on the standards and regulations applicable to a particular pipeline, here is a simplified general formula for calculating MAOP:

MAOP = (2 * S * t) / (D * F)

Where:

- MAOP: Maximum Allowable Operating Pressure (in psi, Pounds per Square Inch)

- S: Stress value for the material (in psi)

- t: Wall thickness of the pipeline (in inches)

- D: Outside diameter of the pipeline (in inches)

- F: Safety factor

This formula provides a basic understanding of how MAOP is calculated. However, in practice, the calculation can be more complex and may involve additional factors such as temperature, corrosion allowance, and specific regulatory requirements.

Here’s a brief explanation of each parameter:

- Stress Value (S): The stress value depends on the material of the pipeline. Different materials have different allowable stress values, which are determined by industry standards and codes. These values are typically conservative to ensure safety.

- Wall Thickness (t): The wall thickness of the pipeline refers to the thickness of the pipe wall. It plays a crucial role in determining the pipeline’s ability to withstand pressure.

- Outside Diameter (D): The outside diameter is the measurement of the pipeline’s outer circumference. It is also an important factor in calculating MAOP.

- Safety Factor (F): The safety factor is a multiplier that accounts for various safety considerations, including uncertainties in material properties, manufacturing processes, and potential transient pressure variations. Common safety factors range from 1.25 to 1.5, but they can vary depending on regulatory requirements.

Please note that this formula provides a simplified overview of MAOP calculation. In practice, engineers and pipeline operators follow specific codes and standards (such as ASME B31.4 for liquid pipelines or ASME B31.8 for gas pipelines in the United States) to ensure accurate and compliant MAOP calculations. The actual calculation may involve more detailed considerations and may vary based on the specific characteristics of the pipeline and applicable regulations. Additionally, the calculation may need to account for factors like material properties, temperature, corrosion, and other variables that can affect pipeline integrity. Consulting with a qualified engineer or expert in pipeline design and regulations is essential for accurate MAOP determination.

So now we need to understand SYMS.

What is SYMS?

SMYS stands for “Specified Minimum Yield Strength.” It is a critical mechanical property of materials used in the construction of pipelines and other pressure-containing components, particularly in the oil and gas industry. SMYS represents the minimum amount of stress or load that a material must be able to withstand without experiencing permanent deformation or failure.

The specified minimum yield strength (SMYS) and its significance in pipeline construction and operation. Here’s a summary of the key points:

SMYS is a yield strength value specified for the steel when purchased, and it must be documented in the grade certification for the material. This documentation is essential for ensuring the proper selection of materials with the required strength characteristics.

When constructing a pipeline, the operator specifies the SMYS required for the project based on factors such as operating conditions, fluid characteristics, and safety considerations.

Pipe manufacturers often produce multi-grade pipe joints with a single certificate specifying multiple grades of steel. As a result, the actual pipe received may exceed the minimum SMYS required for the project. However, the operator is typically limited to running the pipeline at the pressure for which it was designed, even if the pipe’s material exceeds the minimum requirements.

SMYS is a crucial parameter in the calculation of the Maximum Allowable Operating Pressure (MAOP) of a pipeline. A factor of safety, typically 0.72 or lower, is applied to the SMYS in the MAOP calculation to ensure safe operation.

When documentation, such as a grade certificate or material test report (MTR), is missing for a pipeline, the operator faces challenges in determining the SMYS. In such cases, conservative assumptions may be made, or mechanical properties may need to be measured.

The Automated Ball Indentation (ABI) test method, following ASTM Standard E636-14, is a nondestructive technique used to measure the mechanical properties of in-service oil and gas pipelines. It provides direct property measurements and is accepted by regulatory authorities such as the Pipeline and Hazardous Materials Safety Administration (PHMSA) and states like California (CA) and Washington (WA).

The ABI test method offers precise measurements of pipeline properties and is a valuable tool for operators to determine the strength characteristics of their pipelines without the need for destructive testing.

So now we need to understand about What is Grade in Piping.

What is Grade in Piping?

In piping and pipeline systems, the term “grade” typically refers to the specific type or quality of material used in constructing the pipes. The grade of piping material is a key consideration in pipeline design and construction, and it is often specified based on the intended application, operating conditions, and regulatory requirements. Here are some important aspects of grades in piping:

The determination of grades in piping materials, including the chemical composition and mechanical properties of pipe steel. Here is explanation further emphasizes the critical role of these factors in ensuring the integrity and safety of pipelines. Here’s a summary of the key points we’ve highlighted:

- Chemical Composition: The grade of pipe steel is determined by its chemical composition, which must conform to standards defined in the American Petroleum Institute (API) Specification 5L (API 5L). This specification outlines the acceptable levels of various elements in the steel.

- Chemical Analysis: The chemical analysis of pipe steel includes the measurement of several elements, such as carbon, manganese, phosphorus, sulfur, chromium, columbium, copper, molybdenum, nickel, silicon, titanium, and vanadium. These elements play a crucial role in defining the material’s properties and suitability for specific applications.

- Mechanical Properties: Key mechanical properties that must be measured include yield strength and ultimate tensile strength. Yield strength marks the point at which the steel begins to deform plastically, while ultimate tensile strength represents the maximum stress the steel can withstand before necking in a tensile test specimen.

- Yield-to-Tensile Strength Ratio: The ratio between yield strength and ultimate tensile strength is an important criterion. It should not exceed 0.93 to ensure sufficient ductility and fracture toughness of the steel. Steels with ratios exceeding this limit are considered brittle and at higher risk of failure.

- Fracture Toughness: Fracture toughness is a critical property for ensuring a material’s ability to withstand the initiation and propagation of cracks. However, this property is not typically included in a grade certificate. You’ve mentioned the innovative Automated Ball Indentation (ABI) test as a method for measuring fracture toughness in the field nondestructively.

In summary, the determination of grades in piping materials involves a comprehensive assessment of both chemical composition and mechanical properties. These factors are essential for ensuring the safe and reliable operation of pipelines, especially in industries such as oil and gas, where pipeline integrity is of utmost importance. Proper material selection and testing are crucial to meet industry standards and regulatory requirements.

Read Also:

In pipeline safety and material assessment, it’s crucial to be aware of certain practices and technologies related to material identification and property evaluation. Some field service providers offer Positive Material Identification (PMI) services, which can be mistakenly perceived as a means to determine a pipeline’s grade. However, it’s vital to clarify that the PMI technique, primarily designed for measuring chemical composition, was never intended to ascertain the specific steel grade. Instead, it serves to differentiate various metals, such as aluminum, stainless steel, and titanium, to facilitate tasks like scrap metal sorting.

Additionally, it’s worth noting that some chemical composition techniques used in PMI may not provide a direct measurement of carbon content; instead, they rely on calculated estimates. While PMI has its merits in specific applications, it’s essential to recognize that Equation (1) above for Maximum Allowable Operating Pressure (MAOP) calculations, as discussed earlier, does not necessitate chemical composition measurements for grade determination. Therefore, PMI, in this context, may not be directly relevant.

Another technology employed in pipeline assessments is portable hardness testing, although it is not mandated by the 50 CFR, Parts 192 and 195 regulations. These tests, while capable of measuring hardness and potentially estimating ultimate tensile strength, fall short in determining yield strength, a critical parameter for MAOP calculations. Consequently, both PMI and hardness testing may not serve as reliable tools for accurately determining MAOP.

In contrast, the Automated Ball Indentation (ABI) test emerges as a powerful alternative. This innovative testing method excels in measuring the tensile and fracture toughness properties of all carbon steels, regardless of their specific chemical composition or carbon content. Unlike other techniques, the ABI test provides precise data, making it a valuable asset for assessing material properties, especially in the field, where precision is paramount. This test’s ability to directly evaluate tensile and fracture toughness properties positions it as a dependable tool for ensuring pipeline safety and integrity.