In the early design stage of a ship, calculating Ship weight Calculations is vert important for various reasons. This includes determining the total weight, weight distribution, and center of gravity. These parameters are essential for providing cost estimates, as well as for conducting preliminary stability, seakeeping, resistance, and strength analyses.

Ship weight Calculations

Estimating the weight during the early design stages typically involves using parametric models. These models rely on data from similar vessels, which can be obtained from literature or from a shipyard’s database. One key aspect of this estimation process is identifying the relevant independent variables that are correlated with weights and their centers.

As the ship design and building processes progress, the accuracy of weight estimation should improve. This improvement comes from using more accurate methods and incorporating firm drawings into the calculations. Ultimately, the official weight calculation should precisely indicate the weight of the vessel. This calculation is usually validated through activities such as draught surveys and inclining experiments conducted after the ship is launched.

In the preliminary estimation of a ship’s weight, it’s common practice to categorize the weight into distinct groups. These groups typically include the structure weight, machinery weight, equipment weight, and outfitting weight. Each of these parts is estimated separately to provide an overall estimation of the ship’s weight.

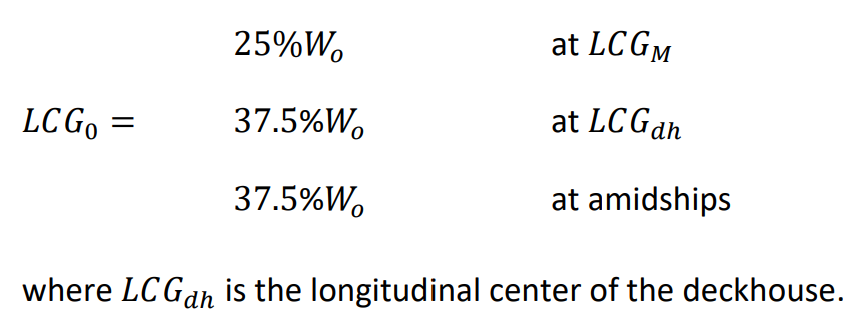

The structural weight comprises several components, including the weight of the basic hull up to its depth amidships, the weight of any superstructures (such as the forecastle and poop deck), and the weight of deckhouses. Superstructures and deckhouses are particularly important because they affect the ship’s vertical and longitudinal centers of gravity. Therefore, capturing the designer’s intentions regarding the existence and location of these structures early in the design process is crucial.

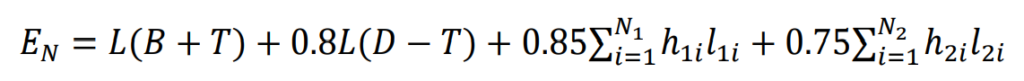

One approach to capturing this information is through the modified Lloyd’s index or numeral, often referred to as the Equipment Numerical EN. This index helps in estimating the weight of equipment and outfitting on board the ship.

The equation introduced by Watson and Gilfillan for estimating the structural weight of a ship as a function of the equipment number includes several terms:

- ܰN1, ℎ1, and ݈L1 represent the number, height, and length of deckhouses, respectively.

- Similarly, ܰN2, ℎ2, and ݈L2 represent the number, height, and length of superstructures, respectively.

This equation is comprised of four main terms:

- The first term accounts for the area of the bottom and the two sides of the hull below the waterline.

- The second term represents the area of the two sides above the waterline, which are estimated to be 15% lighter as they do not experience hydrostatic loading.

- The third term sums up the profile areas (length multiplied by height) of the superstructure elements.

- The fourth term represents the sum of the profile areas of the deckhouse elements, which are relatively lighter because they are not influenced by wave loads and have a width less than the ship’s beam.

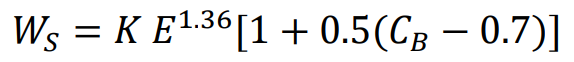

The equation for estimating the structural weight of a ship includes the block coefficient (Cb) at 80% of the depth. Additionally, there is a factor denoted as K, which varies depending on the type of ship. This variation is detailed in Table below. It’s important to note that this estimation assumes the vessel is constructed entirely from steel.

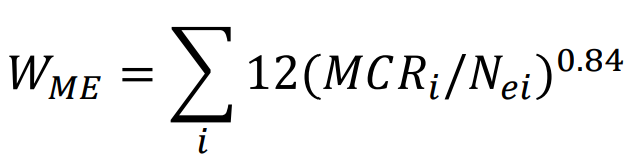

In commercial classification, machinery weight comprises only the propulsion machinery, including the prime mover, reduction gear, shafting, and propeller. Watson and Gilfillan proposed dividing the machinery weight into main engines (Wme) and the remaining items (Wrem). This division is advantageous because it allows for the early selection of the main engine during the design process.

The total machinery weight (Wm) is calculated as the sum of the main engine weight (Wme) and the weight of the remaining machinery components (Wrme):

Wm = Wme + Wrme

If the weight of the main engine is unknown, regression equations can be used to estimate both the main engine and the remaining machinery components.

In the above equations, the subscript “i” represents the index of multiple engines respectively running at a maximum continuous rate, denoted by MCRi, in the order of ܰNei rpm. The overall weight of the remaining items varies with the total plant power, ܴMCR as follows:

Here, MCR is in KW and Cm takes different values depending on the type of ship:

- For bulk carriers, cargo vessels, and container ships: Cm=0.69

- For tankers: Cm=0.72

- For passenger vessels and ferries: Cm=0.83

- For frigates and corvettes: Cm=0.19

This equation is used specifically for modern diesel-electric engines, as proposed by Watson.

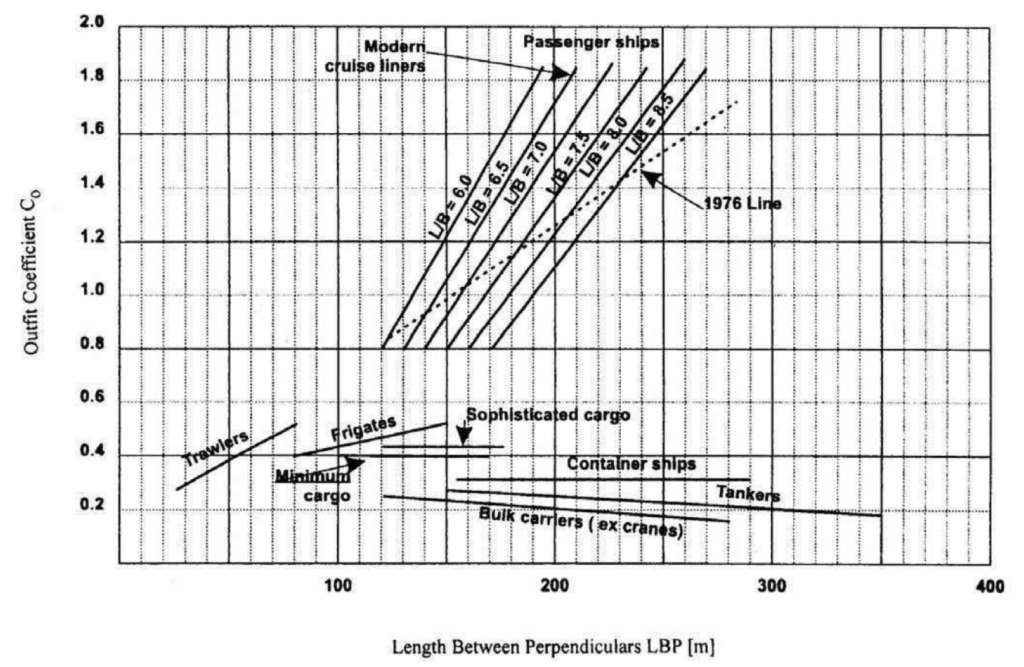

The outfitting weight, which encompasses various components such as electrical plants, auxiliary systems (e.g., HVAC), joiner work, furniture, electronics, paint, as well as hull engineering elements like bits, chocks, hatch covers, cranes, windlasses, winches, etc., is estimated using the equation proposed by Watson and Gilfillan:

Woutfitting=Coutfitting×LB

Here, Co is the outfitting weight coefficient, which is determined based on the ship type and length. The specific values of Co can be obtained from Figure below.

What is Cargo deadweight?

Cargo deadweight refers to the weight of cargo that a ship can carry when fully loaded, excluding the weight of the ship itself, fuel, crew, and any other items not directly related to the cargo. It is a important metric for determining a ship’s capacity and efficiency in transporting goods. The cargo deadweight is calculated by subtracting the lightweight (the weight of the ship without cargo) from the ship’s displacement when fully loaded. It represents the maximum amount of cargo that a ship can transport safely without exceeding its design limits.

Cargo deadweight is typically a requirement specified by the ship’s owner, or it can be estimated by analyzing the hull’s capacity to carry cargo. Other components of deadweight, such as fuel weight, can be estimated similarly to the estimation of lightship weight.

To estimate the fuel weight, the specific fuel consumption rate (SFR) for the propulsion plant is considered. The formula used is:

WFO=SFR×MCR×speed/range×margin

For diesel engines, the SFR is typically 0.00019 tons per kWh, with an additional 10% allowance to account for shipboard operations. For gas turbines, the SFR is around 0.000215 tons per kWh. The overall design margin for SFR might be between 5-10%.

The range/speed parameter indicates the time before refueling is required. In practice, a ship rarely operates at its maximum continuous rate except under extreme conditions. Therefore, this estimation tends to be conservative.

Lube oil weight

The weight of lube oil is determined by the type of machinery installed onboard and is usually obtained from records of existing vessels.

The weight of fresh water depends on the ship designer’s decision regarding onboard distillation and storage capabilities. For instance, modern commercial vessels often carry sufficient water for the entire voyage, while naval vessels and cruise ships may have onboard distillation systems due to higher capacity demands.

Assuming a consumption rate of 45 gallons per person per day, the total water tankage weight required can be calculated as:

WFW=0.17tons/(Person×day)

This estimate would be sufficient for 10 days of storage with distillation or 45 days of storage without distillation onboard.

The weight of the crew and their effects can be estimated as:

WC&E=0.17tons/person

Additionally, the weight of provisions can be estimated using:

Wpr=0.01tons/(person×day)