This article is about requirements for manufacturing, testing and design and basic concept of adjustable frequency drives (AFD) for use with 480 V, 60 Hz motors. Main keywords for this article are Adjustable Frequency Drive for Low Voltage Motors, Variable Frequency Drive, VFD Circuit, Variable Frequency Drive for 3 Phase Motor, Types of VFD.

Variable Frequency Drive References

American National Standards Institute (ANSI)

C62.41 Recommended Practice on Surge Voltage in Low Voltage AC Power Circuits

Institute of Electrical and Electronic Engineers (IEEE)

519 Guide for Harmonic Control and Reactive Compensation of Static Power Converters

National Electrical Manufacturer’s Association (NEMA)

ICS 6 Enclosures For Industrial Controls and Systems

ICS 7 Industrial Control and Systems, Adjustable Speed Drives

ICS 7.1 Safety Standards for Construction and Guide for Selection, Installation and Operation of Adjustable Speed Drive Systems

National Fire Protection Association (NFPA)

70 National Electrical Code (NEC)

Underwriters Laboratories Inc (UL)

796 Printed Wiring Boards

Variable Frequency Drive

Adjustable Frequency Drive for Low Voltage Motors

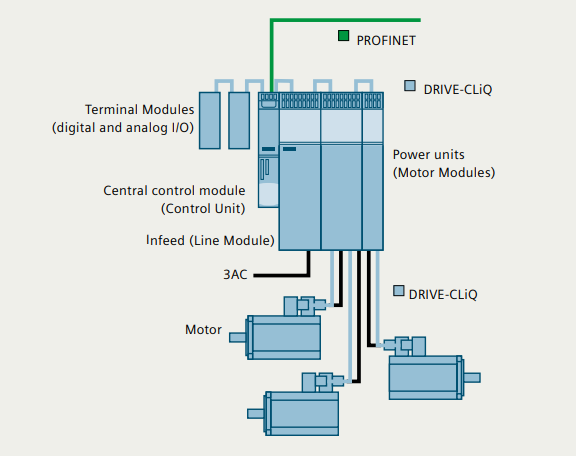

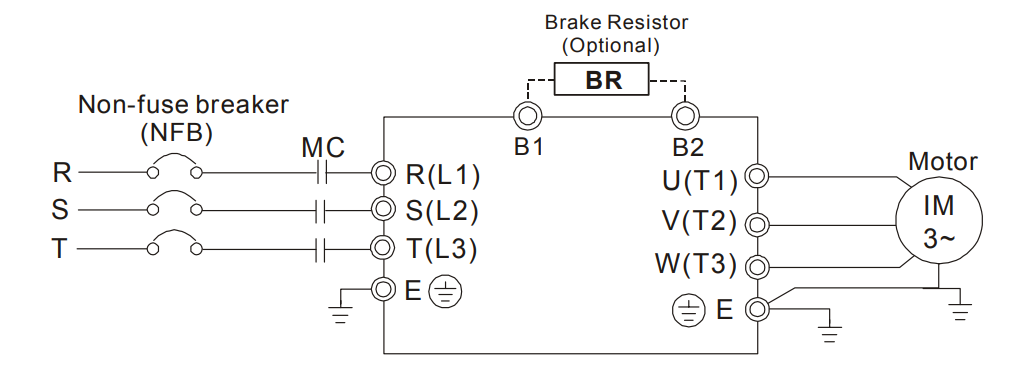

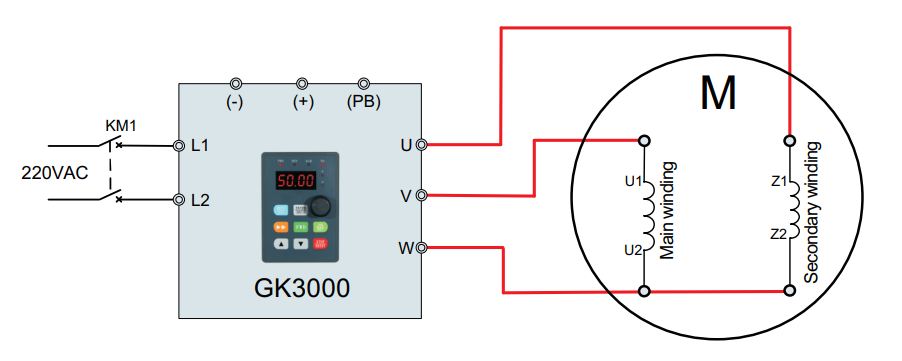

- The drive (motor controller) shall convert 480 V, three-phase, 50 / 60 Hz power to an adjustable voltage (0 -480 V) and frequency (0 – 60 Hz), three-phase, ac power, for stepless motor speed control over the specified speed range. Drive may be furnished as part of a motor control center (MCC) , or as individual equipment in a free standing or wall mounted enclosure.

- Drive shall be designed and manufactured in accordance with NEMA ICS 7 for use on a 3 phase, 60 Hz system with ratings.

- Drive shall be capable of operating an induction motor with a full load current equal to or less than the continuous output current rating of the drive. At 60 Hz and below, drive shall operate in constant volts per Hz mode. Above 60 Hz, drive may selectively operate in either a constant volts per Hz mode or constant voltage extended frequency mode.

- Drive shall be provided with a maintenance bypass switch, to allow the motor to be operated at normal speed when the drive is being maintained.

- Drive shall be designed and manufactured in a way that with the failure of any one component, drive shall still operate the motor.

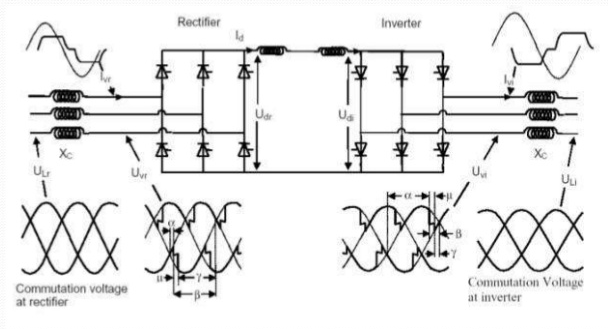

VFD Circuit

Variable Frequency Drive for 3 Phase Motor

Types of VFD

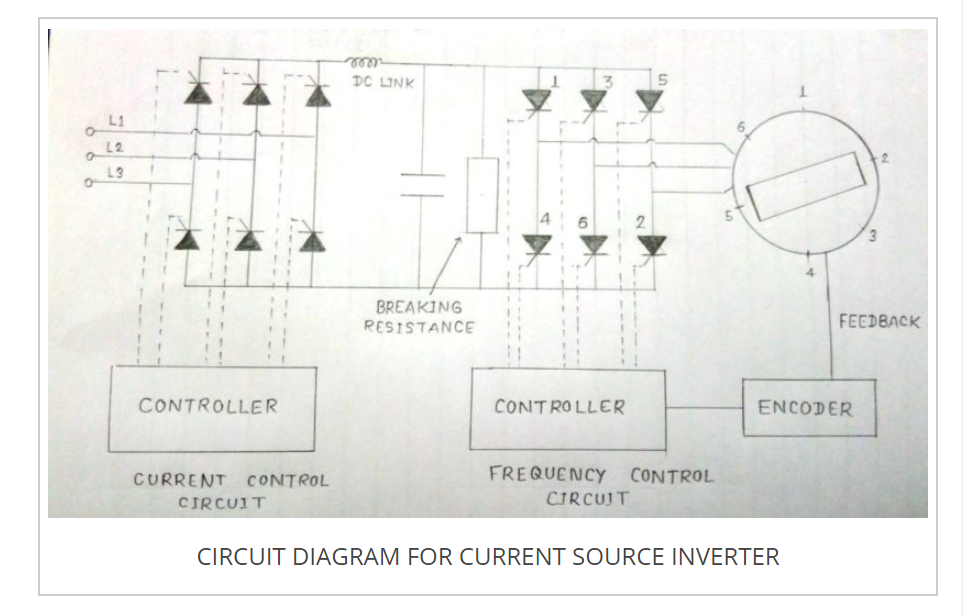

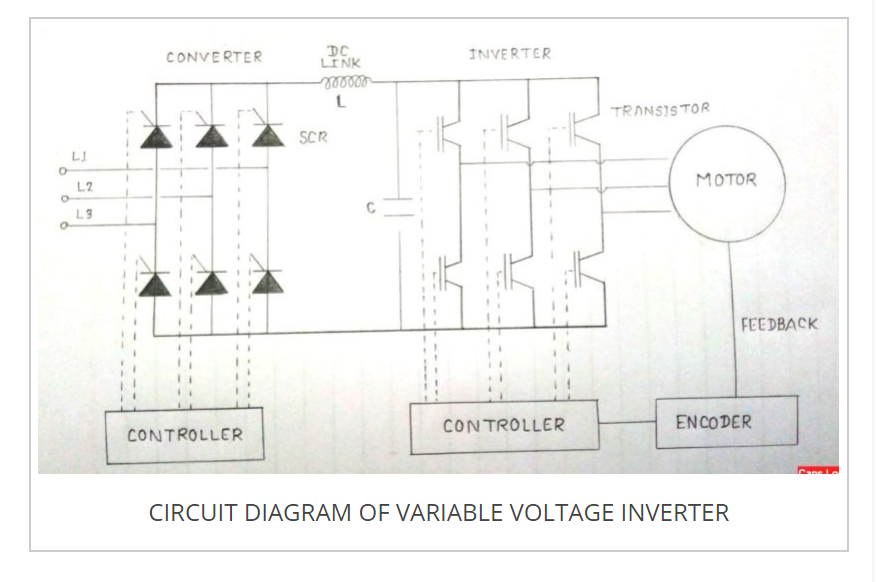

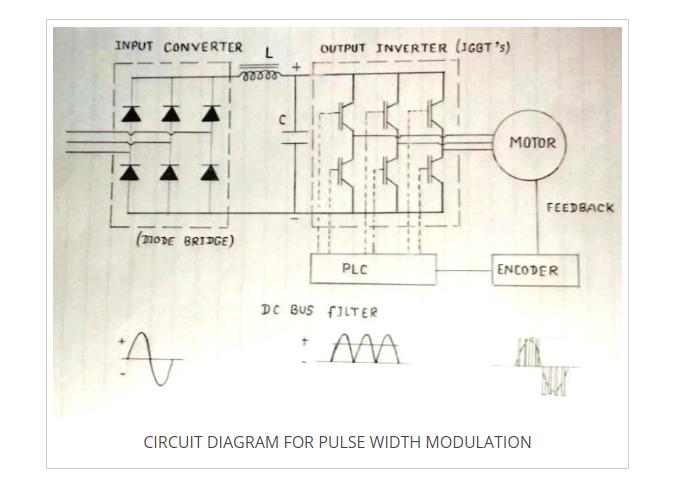

The most common types of VFDs are:

Current source inversion or CSI

Voltage source inversion VSI

Pulse-width modulation PWM

Load commutated inverter LCI

Adjustable Frequency Drive Performance

- Drive shall be capable of operating on a steady state basis with input voltage variations of ±10 percent voltage and ±2 percent frequency. An output voltage regulator shall be provided to automatically maintain correct V/Hz ratio within 1 percent of set point, despite incoming voltage variations.

- Drive shall provide near harmonic free operation to the connected power source. Individual or simultaneous operation of drives shall not add more than 3 percent total harmonic voltage distortion and no more than 5 percent total harmonic current distortion to the normal bus, in accordance with IEEE 519. If harmonic filters are necessary to meet these requirements, drive vendor shall provide the filter, and be responsible for the design and manufacturing of the filter. Compliance shall be verifiable by field measurements of harmonic distortion differences at point of common coupling (the drive input) with and without drive operating.

- Drive shall have a minimum efficiency of 97 percent when measured at rated output and torque.

- Drive output current shall approximate actual sinewave current. The output voltage and frequency shall vary proportionally, thus maintaining a constant V/Hz value up to a nominal frequency. Above that nominal frequency, output voltage shall remain constant, thus causing drive to operate in the constant kVA range.

- The controller shall be sized to provide a continuous output current rating of 115 percent of motor nameplate current including any motor service factor. Drive shall be designed to limit electromagnetic interference (EMI) in

accordance with FCC Part 15, Sub Part J for class A devices.

Adjustable Frequency Drive Basic Design

- Drive shall be a sine-coded pulse-width modulated (PWM) design. For drives that incorporate inverse gate bipolar transistor (IGBT) technology, special care shall be taken in coordination of the motor with the drive. Drive shall comply with NEMA ICS 7.

- Drive shall be suitable for operating on a 480 V power supply system with system grounding.

- The inverter output shall be generated by power transistors with the PWM controlled by a microprocessor, which generates a sine-coded output voltage. The AFD shall not induce excessive power losses in the motor. The worst case RMS motor line current measured at rated speed, torque and voltage shall not exceed 1.05 times the rated RMS motor current for pure sine wave operation.

- Drive shall be pre-programmed for the ramp-up and ramp-down times and shall be re-programmable in the field to allow for changes.

- Drive shall be capable of starting and accelerating the motor and its load to a pre-selected speed.

- Drive shall be designed and constructed in a way that it shall not be damaged by operating with the output open circuited. Drive shall safely limit the output current to 230 percent of the drive nominal ampere rating for output fault conditions.

- Drive input and output shall have surge protection in accordance with ANSI C62.41.

- Drive shall be designed using modular functional subsystems. The sub-system limits shall be selected to group components by function and common operational characteristics. The sub-systems shall facilitate maintenance and help ensure safe working conditions for the mechanic.

- Printed circuit boards shall be high quality industrial grade with keyed, gold plated edge connectors. Circuit boards shall conform to UL 796.

- The boards and components shall be high temperature rated, and be suitable for operation in module enclosures with only internal natural draft air circulation.

{Main keywords for this article are Adjustable Frequency Drive for Low Voltage Motors, Variable Frequency Drive, VFD Circuit, Variable Frequency Drive for 3 Phase Motor, Types of VFD.}

Adjustable Frequency Drive Enclosure

- All drive components shall be factory mounted and wired in a dead front, grounded enclosure. The enclosure shall be a section of an MCC lineup or a stand-alone enclosure.

- Drive enclosure shall be in conformance with NEMA ICS 6, and suitable for installation in an indoor, unclassified area.

- All enclosure openings exceeding 6 mm in width shall be provided with stainless steel screens to prevent the entrance of, for example, snakes and rodents. The maximum screen mesh opening width shall be 6 mm.

- The enclosure shall be designed for front access only, and side by side and back to wall mounting.

- All field connections, control and power shall be made on terminal blocks external to the drive components inside the enclosure.

- The enclosure door shall be interlocked to prevent opening with the main disconnect in the closed position.

- The enclosure ventilation system shall meet the heat dissipation requirements of the drive at full load and at the ambient conditions specified. Drive enclosure may be naturally ventilated or forced ventilated as required by the design.

- For force ventilated enclosures, air filters shall be provided on ventilation intake, and shall be of a disposable type that can be easily replaced without shutting down the drive. Fan motors shall be individually fused.

- Each enclosure section shall be provided with space heaters. The space heaters shall be rated for 240 Vac, 1 phase, 60 Hz, and shall operate on 120 Vac, 1 phase, 60 Hz.

Adjustable Frequency Drive Operational Features

- Drive shall have a keypad and digital display that provide control functions and indications including the following: ‘Power On’, ‘Drive Fault’, ‘Run’, stop and start push buttons and a fault reset push button. A ‘Manual-Automatic’ selector switch, and a manual speed control potentiometer shall also be mounted on the door.

- Drive functions and parameter settings shall be software programmable. Drive shall be suitable for direct interface with industry standard communications systems and programmable logic controller (PLC) interface. An RS485 port and an RS232/422 serial port shall be provided for direct field access and remote communication.

- The digital keypad shall allow the operator to enter exact numerical settings. A plain English user menu shall be provided in software as a guide to parameter setting (rather than codes). Drive parameters shall be factory set electrically erasable programmable read-only memory (EEPROM) and resettable in the field through the keypad. Password security shall be available to protect drive parameters from unauthorized personnel.

- The digital display shall provide diagnostic messages and identify parameters in English language without the use of codes. The display shall be capable of simultaneously displaying:

a. Speed demand in percent

b. Output current in amperes

c. Frequency in Hertz

d. Control mode: manual/automatic

e. Total three-phase kW

f. Output voltage - The controller shall start, stop, accelerate, and decelerate the motor under adjustable controlled speed ramps. After ramp-down, ‘Stop’ shall remove power to the motor, not simply provide a zero speed setting.

- Programmable automatic restart after any trip resulting from over current, over voltage, or under voltage shall be provided. For safety, drive shall shut down and require manual reset and restart if the automatic reset/restart function is not successful after one attempt.

- Speed droop shall be provided to reduce the speed of the drive on transient overloads. Drive shall return to the set speed after the transient overload is removed.

- Individually adjustable settings for start, stop, entry, slope, and minimum and maximum speed setpoints shall be provided.

- Analog speed reference input (process control follower) shall be provided. A proportional and integral setpoint process controller with menu driven selection and programming via door-mounted keypad shall be provided.

- The controller shall be able to restart into a connected coasting motor (forward or reverse direction) without resultant damage to the controller, or causing nuisance tripping.

- Provisions for hard wired status indication shall be provided as follows: one Form C contact rated 120 Vac, 3 A for remote ‘Run’ indication; one Form C contact rated 120 Vac, 3 A for remote ‘Fault’ indication; analog outputs shall be provided.

- The acceleration rate shall be independently adjustable.

- The deceleration rate shall be independently adjustable.

- The motor current limit shall be adjustable from 20 to 135 percent of rated current.

- The motor overload trip shall be adjustable from 20 to 135 percent of rated current.

- The frequency shall be adjustable from 0.2 to 400 Hz.

https://www.se.com/ww/en/product-category/2900-variable-speed-drives-and-soft-starters/

Driver and Motor Protection

Drive shall have necessary components to protect itself and the motor against motor overload, motor or drive internal faults, and incoming ac line disturbances. The following shall be included:

a. Short circuit protection for single phase or 3 phase short circuit on drive output terminals

b. Static instantaneous over current and over voltage trip with inverse over current protection

c. Over speed (over frequency) protection

d. Line under voltage protection

e. Power unit over temperature protection

f. DC bus discharge circuit for protection of operator and service personnel

g. Electronic motor overload protection

h. High motor temperature alarm/shut down

Drive shall have a ground fault detection scheme on the output.

Alarms and Data Logging

- A microprocessor based diagnostic system, which includes self-check, shall be furnished to monitor the system and display faults and operating conditions.

- Microprocessor systems shall be products of the drive manufacturer. The system shall store, display and print the last 4 faults or alarms.

- The fault log record shall be accessible via an RS232/RS422 or RS 485 serial link, and line by line on the keypad display.

- Wiring and Terminations

- Terminal blocks shall be provided for connection of external wiring and shall be conveniently located, clearly numbered, and permanently identified.

- Terminal blocks for external power wiring terminations shall be designed to accommodate compression-type wire lugs for drives greater than 40 kW. Mechanical connections may be used for below 40 kW.

- Connection points for inputs and outputs of different voltage levels shall be segregated from each other. If necessary, this may be accomplished through the use of terminal barriers and covers.

- Where wiring is run through a metal sheet or barrier, bushings, grommets, or other mechanical protection shall be provided.

- All internal wiring shall be terminated with no more than two (2) conductors per terminal block point.

- Drive shall have an internal ground connection suitable for terminating a stranded copper ground conductor of the same size as the incoming phase conductors. Ground connections shall be near the incoming and outgoing

power cable termination points. - Minimum wire bending space shall conform to NFPA 70 Table 430-10(b) for termination of the power cable.

- Terminal blocks and each terminal shall be permanently marked with numbers shown on wiring diagrams. Sleeve type wire markers shall be provided on each end of each wire, showing the wire number assigned on wiring and

schematic diagrams.

Adjustable Frequency Drive Test and Inspection

- Each AFD shall be functionally tested with a motor sized for the maximum rating of the drive. As a minimum, the following tests shall be performed:

a. Demonstration of minimum and maximum speed adjustment

b. Demonstration of acceleration and deceleration rate limiting

c. Demonstration of manual speed control

d. Demonstration of speed control from an external signal. The external signal shall be provided from an instrumentation test set supplied by vendor.

e. Demonstration of V/Hz relationship from minimum to maximum speed for ac drives

f. Demonstration of armature and field voltage control over entire operating range

h. Demonstration of the accuracy of the front panel speed indicating meter by comparing its indication with the unit’s output frequency as read with a frequency counter

i. Demonstration of proper operation of all protective, indication, alarm, control and interlock circuits specified in this specification

j. Open input power circuit and immediately re-close

k. Open input power circuit and leave ‘Off’

l. Open drive output circuit

m. Overload drive to 115 percent for 30 minutes

n. Open input control signal circuit o. Reduce input voltage to 90 percent of nominal volts

- Control power shall be applied to microprocessors, printed circuit boards, diagnostic boards and similar devices, (including software) to test for proper operation, sequencing, logic and diagnostics.

- All wiring shall be checked for continuity, and against the wiring diagrams. The test shall be made with a buzzer or bell type continuity tester against a written checklist or drawing.

- Vendor shall determine the AFD efficiency by the summation of the segregated loss method at 1/2 load, 3/4 load, and full load. Table I lists the minimum allowable efficiencies of the AFD and typical efficiencies of a 30 HP motor and AFD/motor combination. The AFD efficiencies shall not be less than specified in Table I.

{Main keywords for this article are Adjustable Frequency Drive for Low Voltage Motors, Variable Frequency Drive, VFD Circuit, Variable Frequency Drive for 3 Phase Motor, Types of VFD.}

{Main keywords for this article are Adjustable Frequency Drive for Low Voltage Motors, Variable Frequency Drive, VFD Circuit, Variable Frequency Drive for 3 Phase Motor, Types of VFD.}