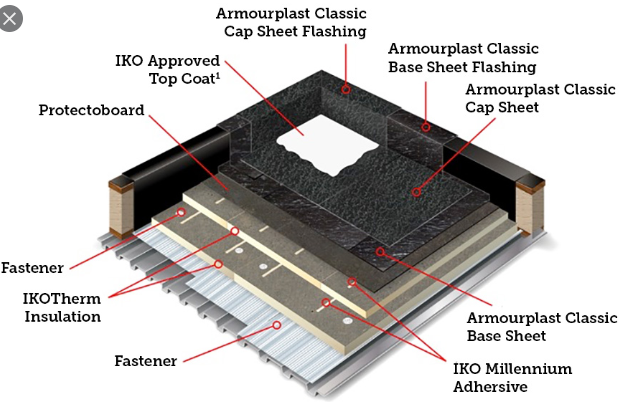

Built–up roofing, also called BUR, is the most common roofing material used on low-slope roofs. It is composed of alternating layers of reinforcing fabric and bitumen (asphalt) and is finished with a top layer of aggregate, such as stone or gravel.

Built-Up Roofing Types, Materials, and Installation

Base-Sheet Materials

Base sheet shall be ASTM D 4601, Type II, non perforated, asphalt-impregnated and -coated, glass-fiber sheet, dusted with fine mineral surfacing on both sides.

Roofing Membrane Plies

-

- Ply sheet shall be ASTM D 2178, Type VI, asphalt-impregnated, glass-fiber felt.

- Cap sheet shall be ASTM D 3909, asphalt-impregnated and -coated, glass-fiber cap sheet, with white coarse mineral-granule top surfacing and fine mineral surfacing on bottom surface.

Flashing Materials

Backer sheet shall be ASTM D 2178, Type VI, asphalt-impregnated, glass-fiber felt.

Flashing sheet shall be Type I or II, polyester-reinforced, APP-modified asphalt sheet, mineral-granule surfaced.

Asphalt Materials

Asphalt primer shall conform to ASTM D 41.

Roofing asphalt shall be ASTM D 312, Type III or IV as recommended by built-up roofing system manufacturer for application.

Miscellaneous Roofing Membrane Materials

-

- Miscellaneous accessories and materials shall be as recommended by roofing system manufacturer for intended use, and shall be compatible with built-up roofing.

- Asphalt roofing cement shall conform to ASTM D 4586, and shall be asbestos free, and of consistency required by roofing system manufacturer for application.

- Mastic sealant shall be polyisobutylene, plain or modified bitumen, nonhardening, nonmigrating, nonskinning, and nondrying.

- Fasteners shall be factory-coated steel fasteners, and metal or plastic, plates meeting corrosion-resistance requirements. They shall be designed for fastening roofing membrane components to substrate; tested by manufacturer for required pullout strength; and acceptable to roofing system manufacturer.

- Metal flashing sheet and trim shall conform to SES A12-S03.

- Aggregate surfacing shall be ASTM D 1863, No. 6 or No. 67, clean, dry, opaque, crushed stone, and free of sharp edges.

Roof Insulation

-

- Preformed roof insulation boards shall comply with requirements and referenced standards, and shall be selected from manufacturer’s standard sizes.

- Glass fiber board insulation shall conform to ASTM C 726, shall combine glass fibers with thermosetting resin binders, and shall be faced on one side with asphalt-coated fiberglass scrim and kraft paper. R-value and thickness shall be as indicated on the drawings.

- Factory-tapered insulation boards shall be fabricated to slope of 6 mm per 30 mm ( in per 12 in) (1:48), unless otherwise indicated on the drawings.

- Preformed saddles, crickets, tapered edge strips, and other insulation shapes shall be provided where indicated, for sloping to drain. They shall be fabricated to slopes indicated.

Insulation Accessories

-

- Roof insulation accessories shall be as recommended by insulation manufacturer for intended use, and shall be compatible with membrane roofing.

- Fasteners shall be factory-coated steel fasteners and metal or plastic plates, meeting corrosion-resistance requirements, designed for fastening roof insulation to substrate, and acceptable to roofing system manufacturer.

- Insulation cant strips shall be ASTM C 208, Type II, Grade 1, cellulosic-fiber insulation board.

- Tapered edge strips shall be ASTM C 726, glass-fiber insulation board. They shall be used at roof perimeter if there is no parapet or vertical wall.

Walkways

Walkway pads shall be mineral-granule-surfaced, reinforced asphaltic composition, slip-resisting pads, manufactured as a traffic pad for foot traffic and acceptable to roofing system manufacturer; 19 mm thick, minimum; sized 600 x 600 mm.

Walkway roof pavers shall be hydraulically pressed, concrete units, square edged with top edges beveled 5 mm, factory cast for use as roof pavers; absorption not greater than 5 percent; sized 600 x 600 mm; compressive strength 17 MPa (2500 psi); thickness 50 mm.