Intended as a reference to “Best Procedure for the Selection of Proportions for Regular, Heavyweight, and Mass Concrete (ACI 211.1-91).” Describes a method for the proportioning of concrete with slumps between zero and 1 in. For aggregates up to 3 in. and consistencies below this range. Maximum dimensions.

Appropriate equipment is described to measure such consistencies. ACI 211.3R-97 ACI Standards Guide for Selecting Proportions for No Slump Concrete.

Specific tables are given to those in ACI 211.1-91 which, together with laboratory tests on fine physical properties and course aggregate, provide details to obtain concrete proportions for a trial mixture.

ACI 211.3R-97 ACI Standards Guide for Selecting Proportions for No Slump Concrete

ACI 211.3R-97 ACI Standards Guide for Selecting Proportions for No Slump ConcreteFor drainage purposes, the new edition also includes chapters on proportioning mixes for roller-compacted concrete, concrete roof tiles, concrete maçonnery units and pervious concrete.

For these specialty applications, examples are provided as an aid in calculating the proportions.

“Basic Selection Practice for Regular, Heavyweight, and Mass Concrete Proportions (ACI 211.1)” includes methods for the proportioning of concrete with slumps greater than 1 in. According to ASTM C143. This guide is an ACI 211.1 extension addressing the proportioning of zero slump concrete.

This guide includes, in addition to the general discussion on the proportioning of no-slump concrete, proportioning procedures for these classes of no-slump concrete: roller-com- pacted concrete (Appendix 4); roof tiles (Appendix 5); concrete masonry units (Appendix 6); and pervious concrete (Appendix 7).

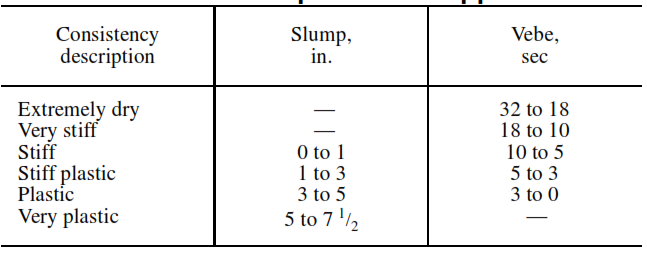

Comparison of consistency measurements for slump and Vebe apparatus

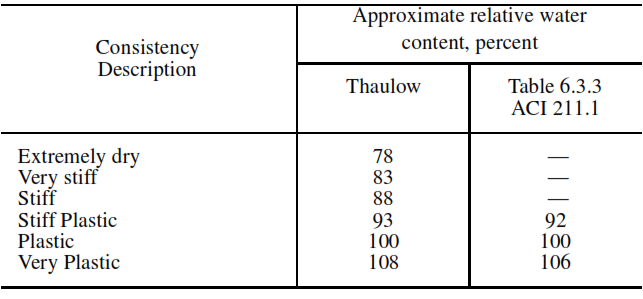

Approximate relative water content for different consistencies

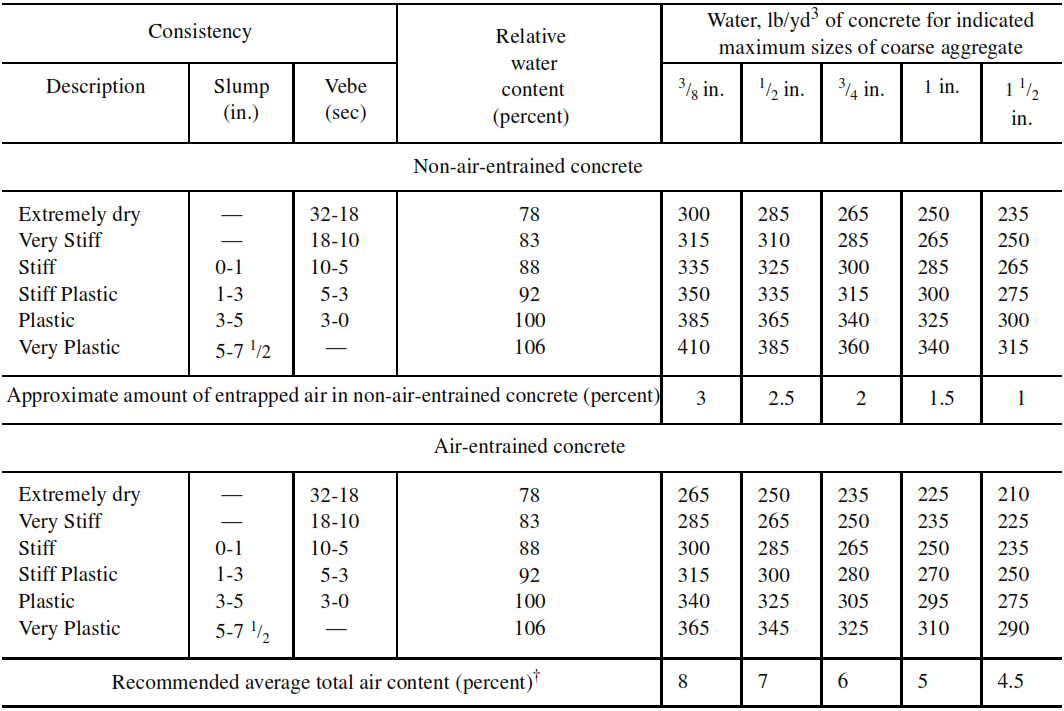

Approximate mixing water requirements for different consistencies and maximum sizes of aggregates

Adjustment of trial mixture

In discussing the calculation of total water requirements provided in Table 2.3.1(c), it was pointed out that in some cases more water may be needed than indicated and that, in such cases, the factor of cemented materials should be increased to preserve the ratio of water cemented materials, unless otherwise indicated by laboratory tests.

This modification will be explained by saying that the example concrete was located in the field requiring 240 lbs of mixing water instead of 225 lbs.

Accordingly, the content of cemented materials should be increased from 523 to (240/225)= 523= 558 lb per cubic yd and the quantities of the batch should be recommended accordingly.

Sometimes less water may be needed than shown in Table 2.3.1(c), but it is recommended that no change be made in the factor of cemented materials, except as indicated by laboratory tests. It is necessary to adjust the batch quantity to compensate for the volume loss due to the reduced water.